Dynamic simulation method for dozer blade inclined mechanism

A dynamic simulation and tilt mechanism technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as non-compliance with the force law of the hoisting cylinder, large errors, and inconsistency with the inclination principle of the bulldozer blade. Accurate effect of bulldozer tilt dynamics simulation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] Taking a certain type of bulldozing blade as an example, using the method of the present invention, the simulation analysis of the tilting dynamics of the bulldozing blade is carried out; by checking the displacement curve of the hinge point of the right lifting cylinder, it is proved that the method meets the kinematic requirements; The force of the lift cylinder, left and right trunnion hinge points proves that this method meets the mechanical requirements. The specific implementation process is as follows:

[0044] 1) According to the tilt mechanism of the bulldozer blade, a dynamic model of the tilt of the bulldozer blade is established, and the kinematics simulation is performed on the model. details as follows:

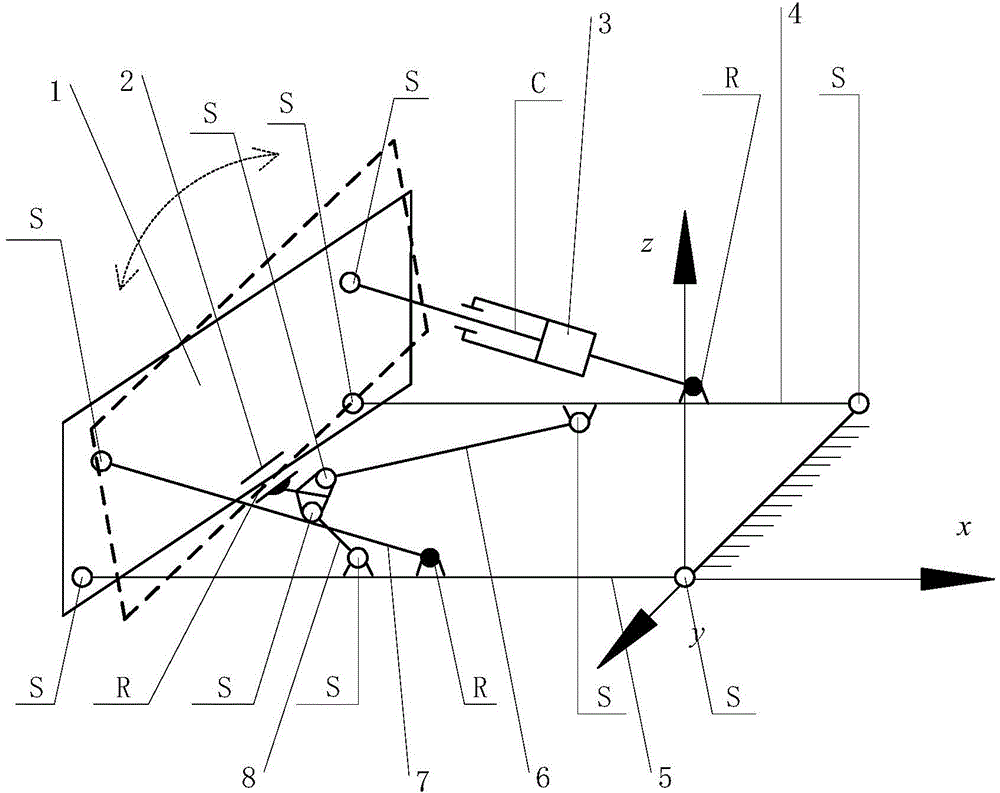

[0045] Such as figure 1 As shown, the established dynamic model includes cutter head 1, bracket 2, tilt cylinder 3, right push rod 4, left push rod 5, right diagonal support 6, diagonal support screw 7, left diagonal support 8 and left and right lifting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com