Automatic tuning method and system for cavity filter

A cavity filter and automatic tuning technology, which is applied in the field of filters, can solve problems such as difficult automation system implementation, time-consuming and labor-intensive work, and high requirements for worker experience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

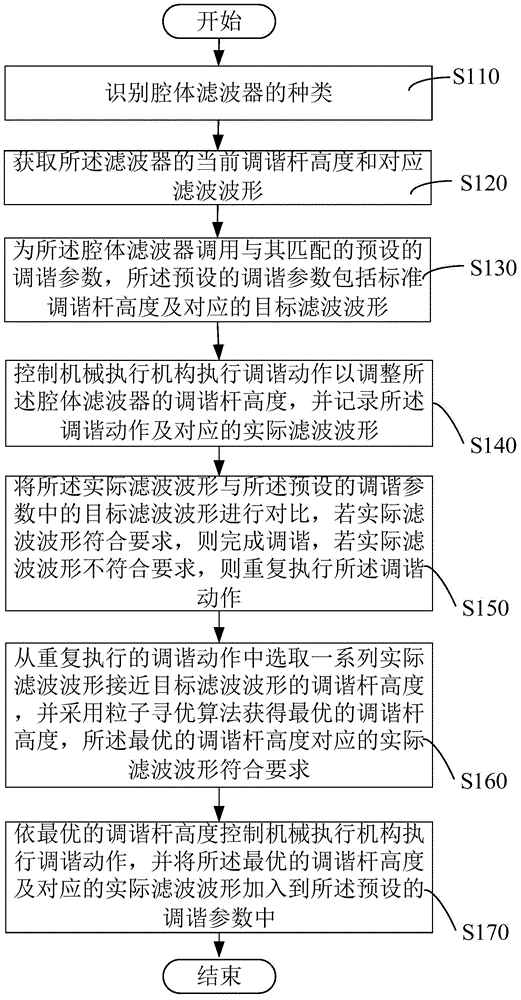

[0026] A preferred implementation of an automatic tuning method for a cavity filter will be described below with reference to the accompanying drawings.

[0027] Please refer to figure 1 , an automatic tuning method for a cavity filter, comprising the following steps:

[0028] S110, detecting the type of the cavity filter. In this step, the marks provided on the cavity filter can be recognized by means of machine vision, so as to identify different types of cavity filters, so as to facilitate subsequent calling of unused tuning parameters, and then perform tuning actions.

[0029] S120. Acquire the current tuning rod height and the filter waveform of the filter. The current height of the tuning rods is obtained by manual input, and the filtered waveform corresponding to the current height of each tuning rod is detected by a vector network analyzer.

[0030] S130. Invoke preset tuning parameters matched with the cavity filter, where the preset tuning parameters include a sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com