Modularized combined-type lifting device for transformer bell cover

A combined transformer and hoisting device technology, applied in the direction of hoisting device, lifting frame, etc., can solve the problems of unsatisfactory work performance and great influence of operator skills.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

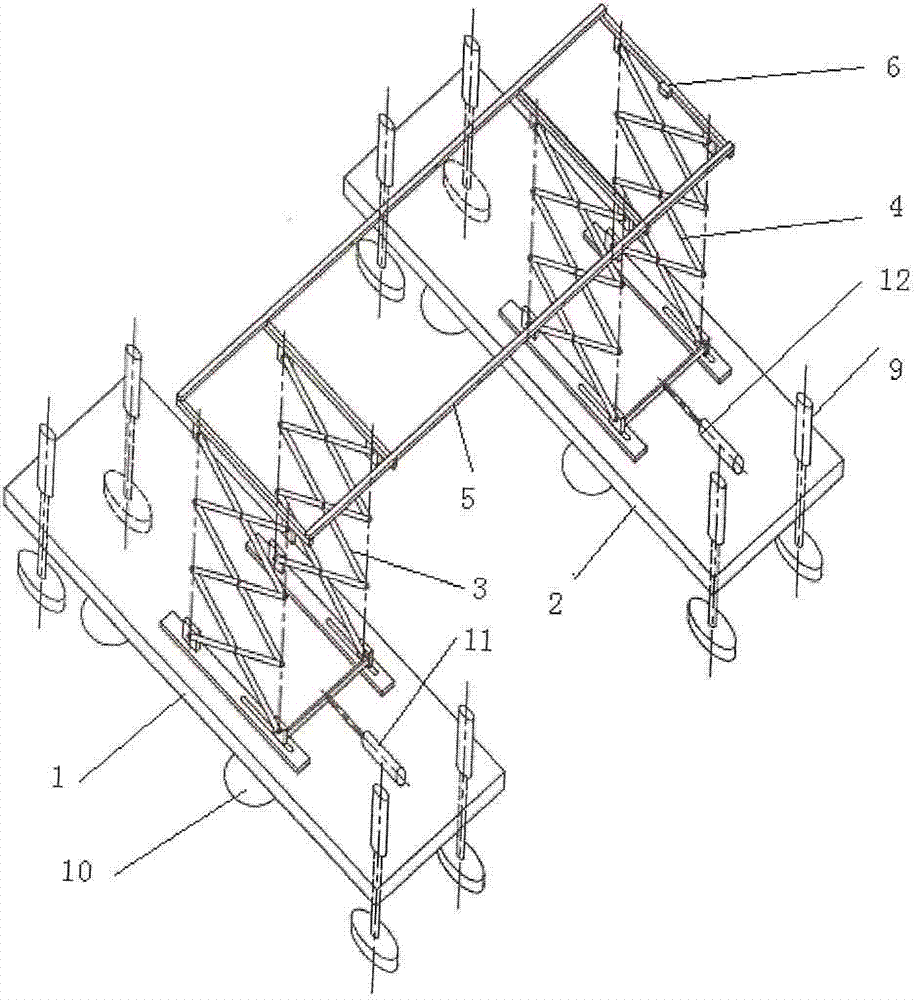

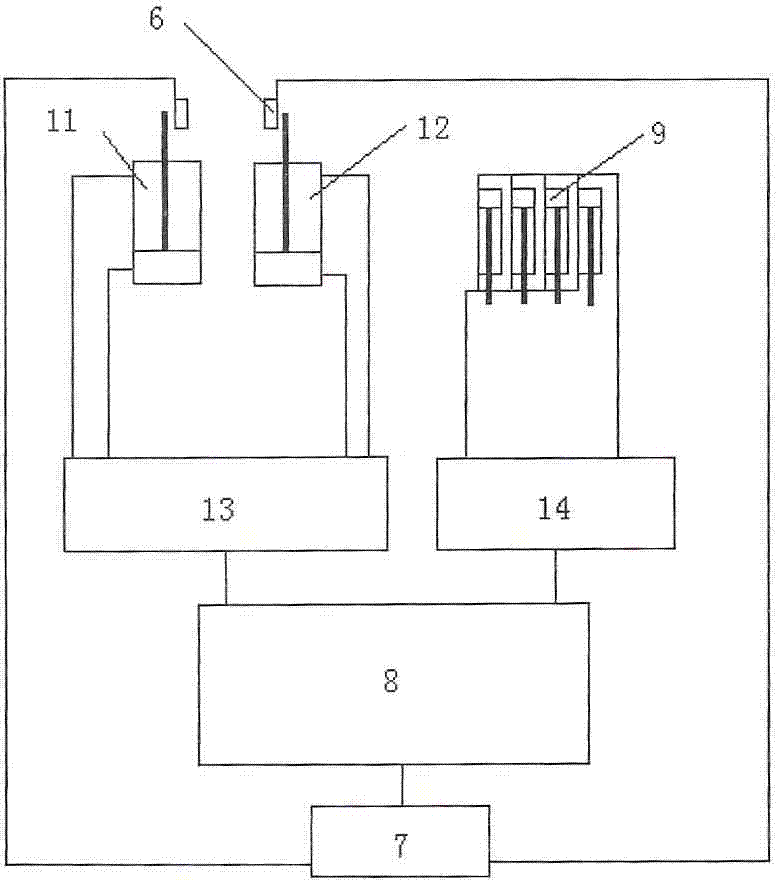

[0013] A modularized combined transformer bell hoisting device, comprising left and right base modules 1, 2, left and right double scissor lifting modules 3, 4 respectively installed on the left and right base modules to be lifted and lowered by left and right hydraulic cylinders , the top of the left and right double scissor lifting modules is equipped with a crossbeam module 5, and the crossbeam module is equipped with a hook for lifting the transformer hanging bell; a displacement sensor 6 is installed on the crossbeam module to detect whether the lifting height of the left and right double scissor lifting modules is consistent The displacement sensor is connected with the control module 7, and the main frame 8 of the control module is connected with the synchronous control device 13 that controls the synchronous movement of the left and right hydraulic cylinders 11, 12;

[0014] When working, the host computer of the control system issues instructions, the left and right hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com