Lubricant passage way of diesel engine suitable for solving scuffing of cylinder bore of engine and working method of lubricant passage way

A lubricating oil circuit, diesel engine technology, applied in the direction of engine lubrication, engine components, machines/engines, etc., can solve the problems of engine pulling, cylinder pulling, slow oil, etc., and achieve the effect of pulling the cylinder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

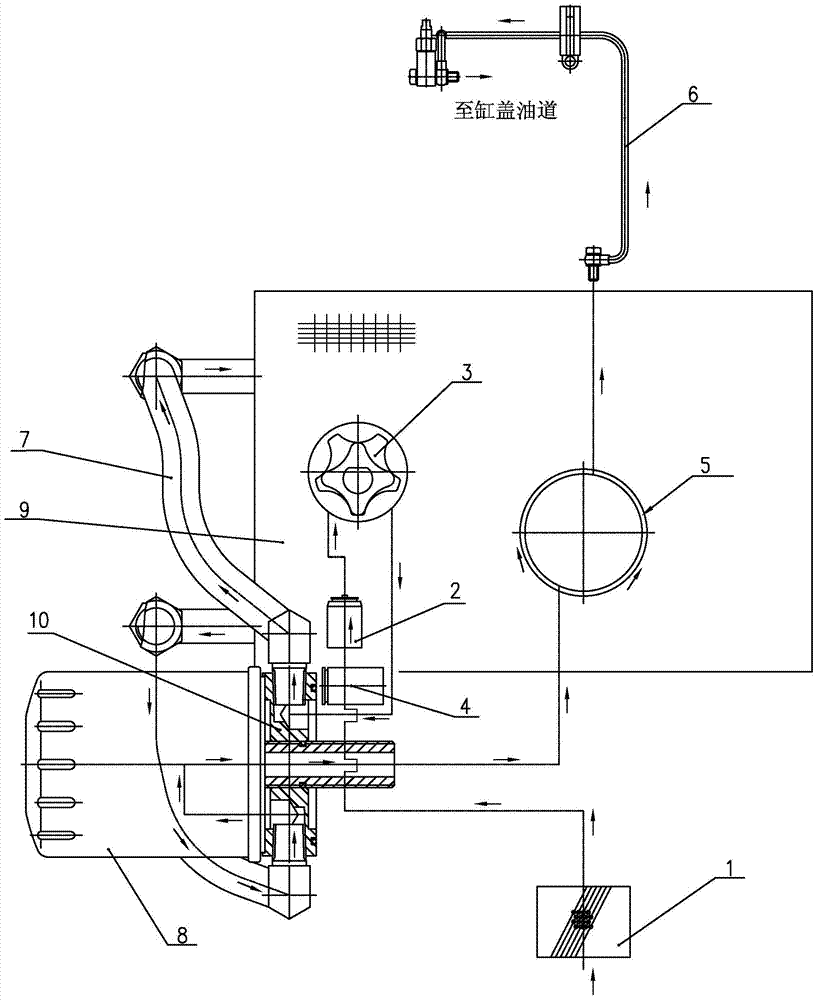

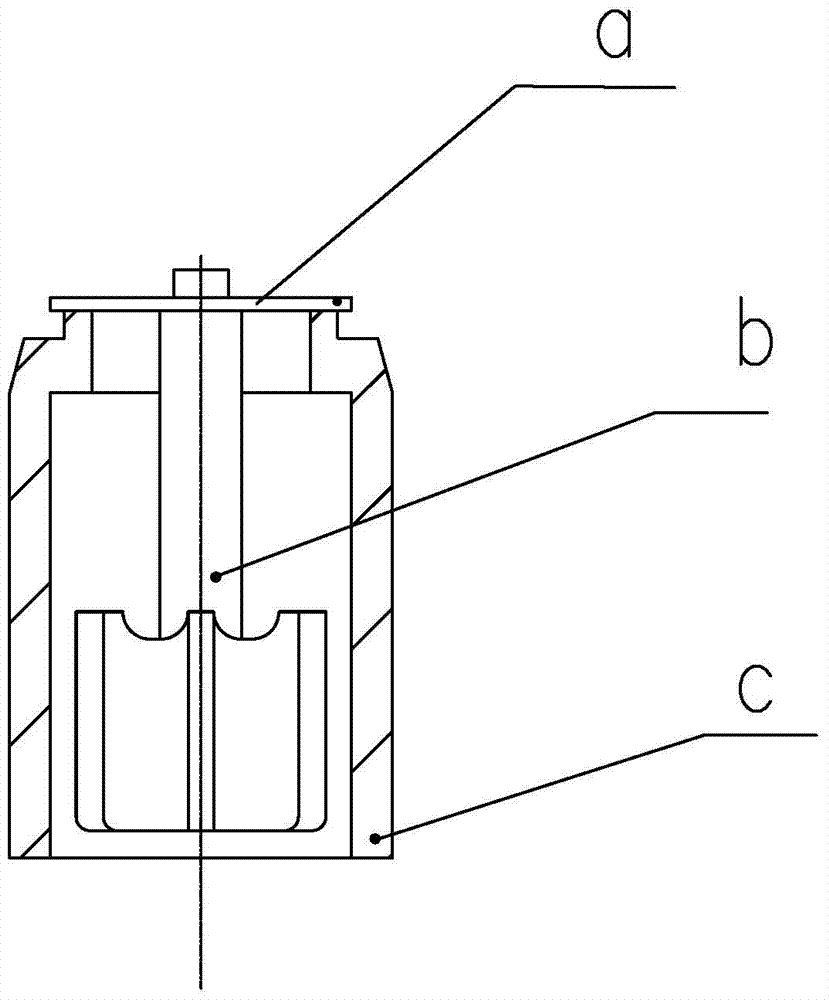

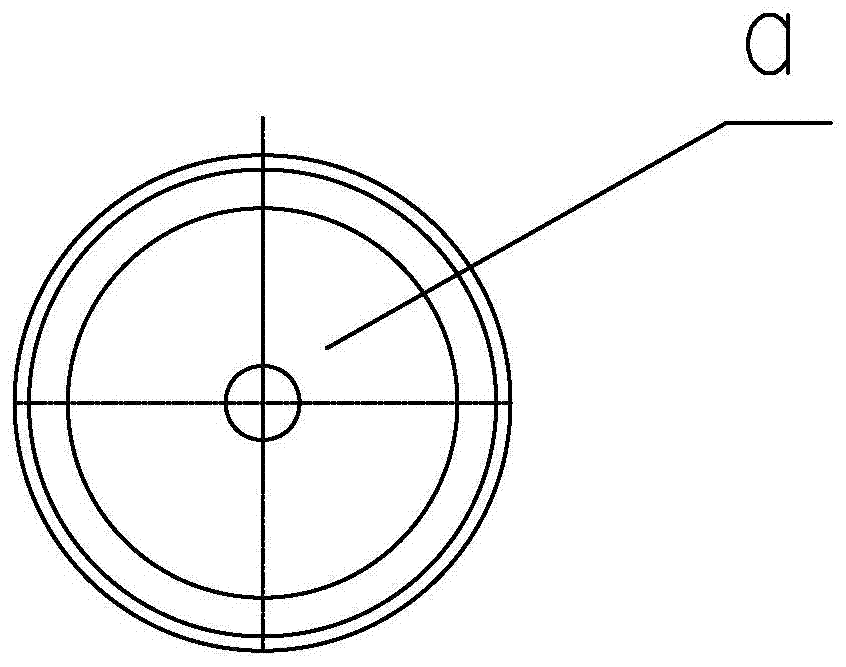

[0021] See Figures 1 to 6 , the lubricating oil path of the diesel engine of the present embodiment comprises: an oil sump, a vertical oil inlet passage connected to the oil sump arranged in the diesel engine block, and a machine oil in the vertical oil inlet passage prevented from entering the vertical oil passage at the bottom of the vertical oil inlet passage. The one-way valve 2 that returns to the oil pool, the coarse filter 1 (the coarse filter 1 is a fine mesh plate) located at the bottom of the one-way valve 2, and the machine connected to the top of the vertical oil inlet. oil pump 3. A one-way valve 2 is arranged between the oil pump 3 and the oil pool, which can prevent all the oil in the vertical oil inlet passage from flowing back into the oil pool after the machine stops, that is, after the machine is stopped, the machine oil is sealed in the oil pool by using the one-way valve. The above vertical oil inlet passage, when restarting, the oil pump can quickly pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com