A two-degree-of-freedom flexible parallel alignment device with a remote center of rotation

A technology of alignment device and degrees of freedom, applied in manufacturing tools, program-controlled manipulators, manipulators, etc., can solve the problems of poor system dynamic performance and cumulative error of the mechanism.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

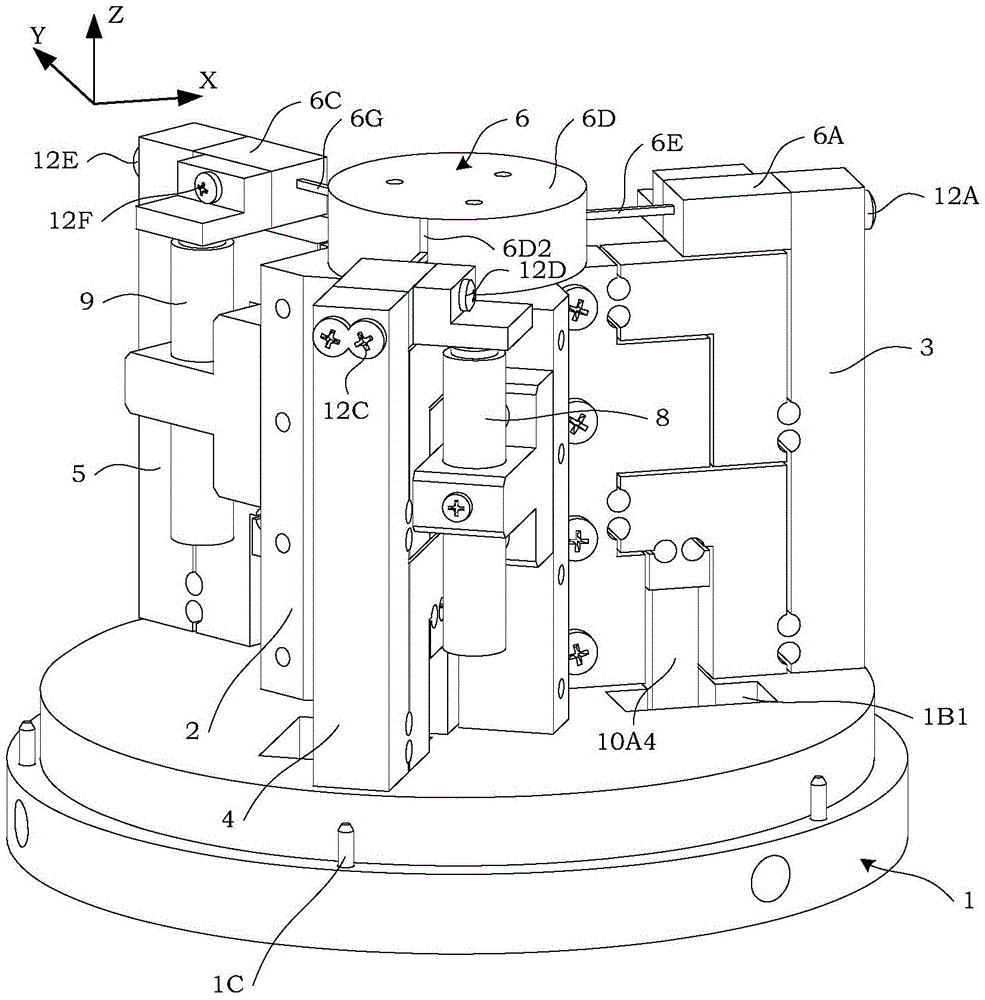

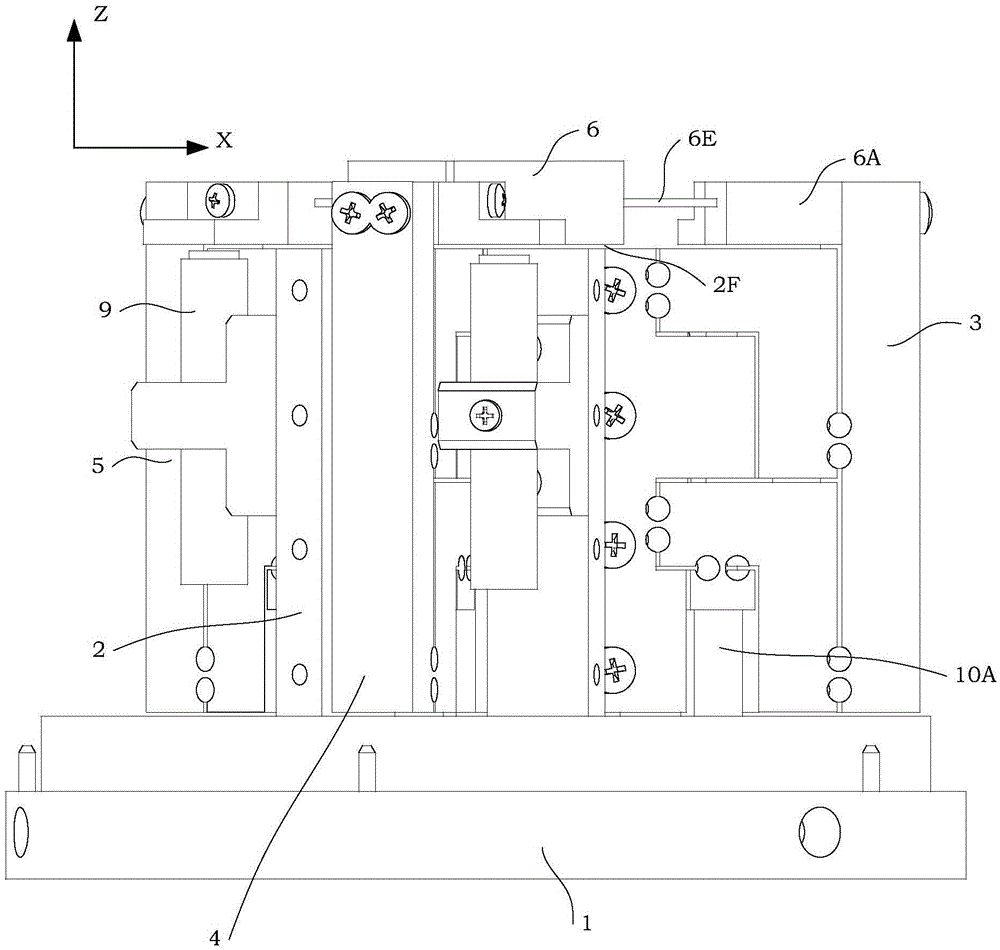

[0081] The present invention will be further described in detail below in conjunction with the accompanying drawings.

[0082] see figure 1 , Figure 1A , Figure 1B , Figure 1C , Figure 1DAs shown, the present invention designs a two-degree-of-freedom flexible parallel alignment device with a remote center of rotation. The two-degree-of-freedom flexible parallel alignment device includes a base 1, an outer sleeve 11, a support seat 2, a first movement Transmission mechanism 3, second motion transmission mechanism 4, third motion transmission mechanism 5, force output platform 6, first measurement component 7, second measurement component 8, third measurement component 9, first drive component 10A, second drive assembly 10B and a third drive assembly 10C.

[0083] Wherein, the structure of the first motion transmission mechanism 3, the second motion transmission mechanism 4 and the third motion transmission mechanism 5 is the same, and the first motion transmission mech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com