Liquefied gas storage tank and application method thereof

A gas and storage tank technology, applied in the field of gas liquefied storage tanks, can solve the problems of gas liquefied loss, waste, and system inability to start, etc., and achieve the effect of strong cold storage capacity and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

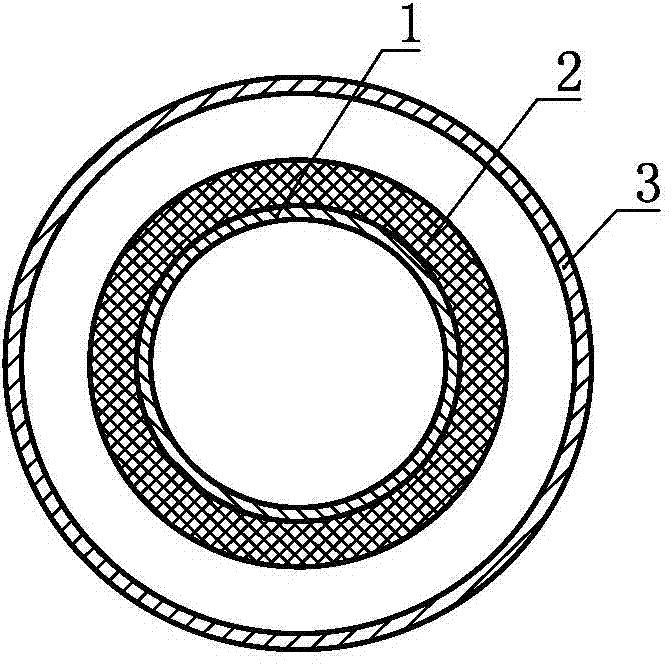

[0034] A gas liquefied storage tank, such as figure 1 As shown, it includes an inner cavity body 1, a heat insulation layer 2 and an outer cavity body 3, the heat insulation layer 2 is arranged on the outside of the inner cavity body 1, and the outer cavity body 3 is arranged on the heat insulation layer 2 The space inside the inner cavity 1 is a gas liquefied storage space, and the inner cavity 1 communicates with the outer cavity 3 .

[0035] As an alternative embodiment, on the basis of Example 1, the inner cavity 1 , the heat insulation layer 2 and the outer cavity 3 are further nested and arranged sequentially from the inside to the outside.

Embodiment 2

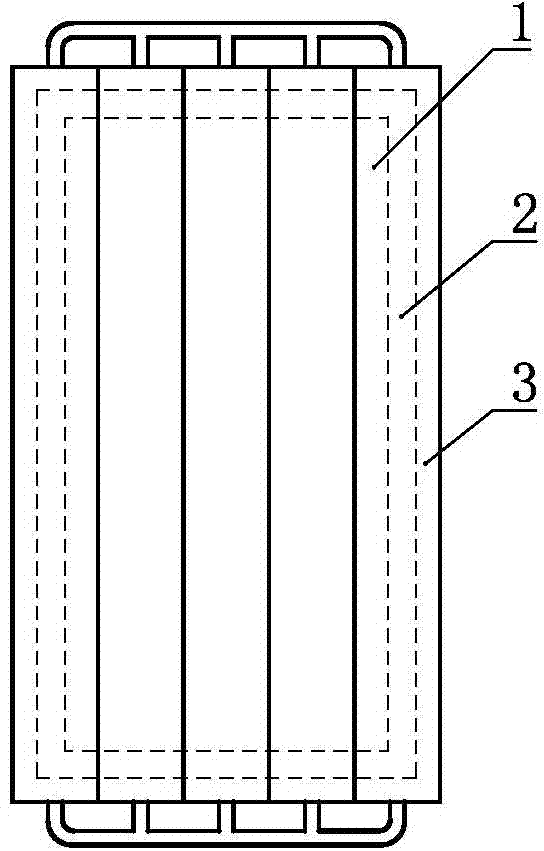

[0037] A gas liquefied substance storage tank, on the basis of Embodiment 1, the outer cavity 3 can be further set as a parallel tubular outer cavity with multiple tubes connected in parallel (such as figure 2 shown).

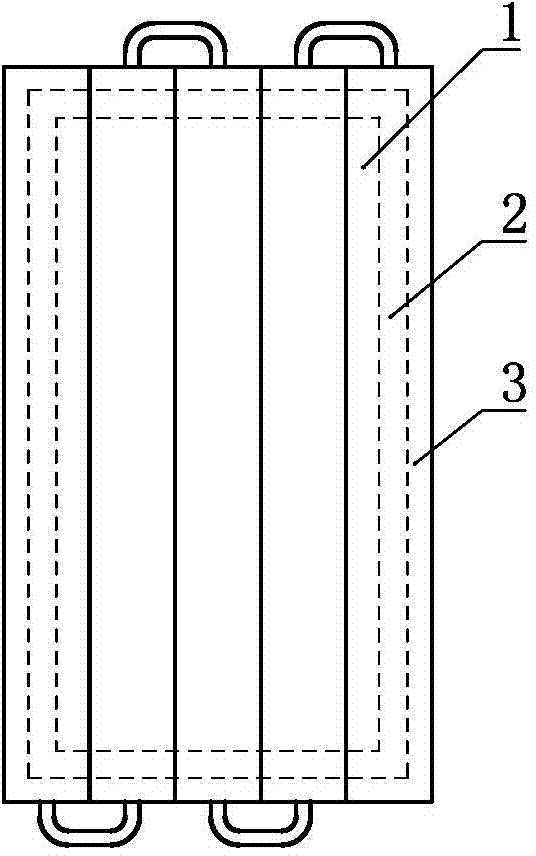

[0038] As a changeable embodiment, on the basis of Example 1, the outer cavity 3 can be further set as a series tubular outer cavity with multiple tubes connected in series (such as image 3 shown).

Embodiment 3

[0040] A gas liquefied storage tank, such as Figure 4 As shown, on the basis of Embodiment 1, the gas liquefied substance storage tank further includes an auxiliary heat insulation layer 21 , and the auxiliary heat insulation layer 21 is arranged on the outside of the outer cavity 3 .

[0041] As a changeable implementation manner, both Embodiment 1 and Embodiment 2 and their changeable implementation manners can further make the gas liquefied substance storage tank further include an auxiliary heat insulation layer 21, and the auxiliary heat insulation layer 21 is arranged on the The outside of the outer cavity 3 is described.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com