Treatment method for sewage

A treatment method and technology for wastewater, which can be applied in the directions of oxidized water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

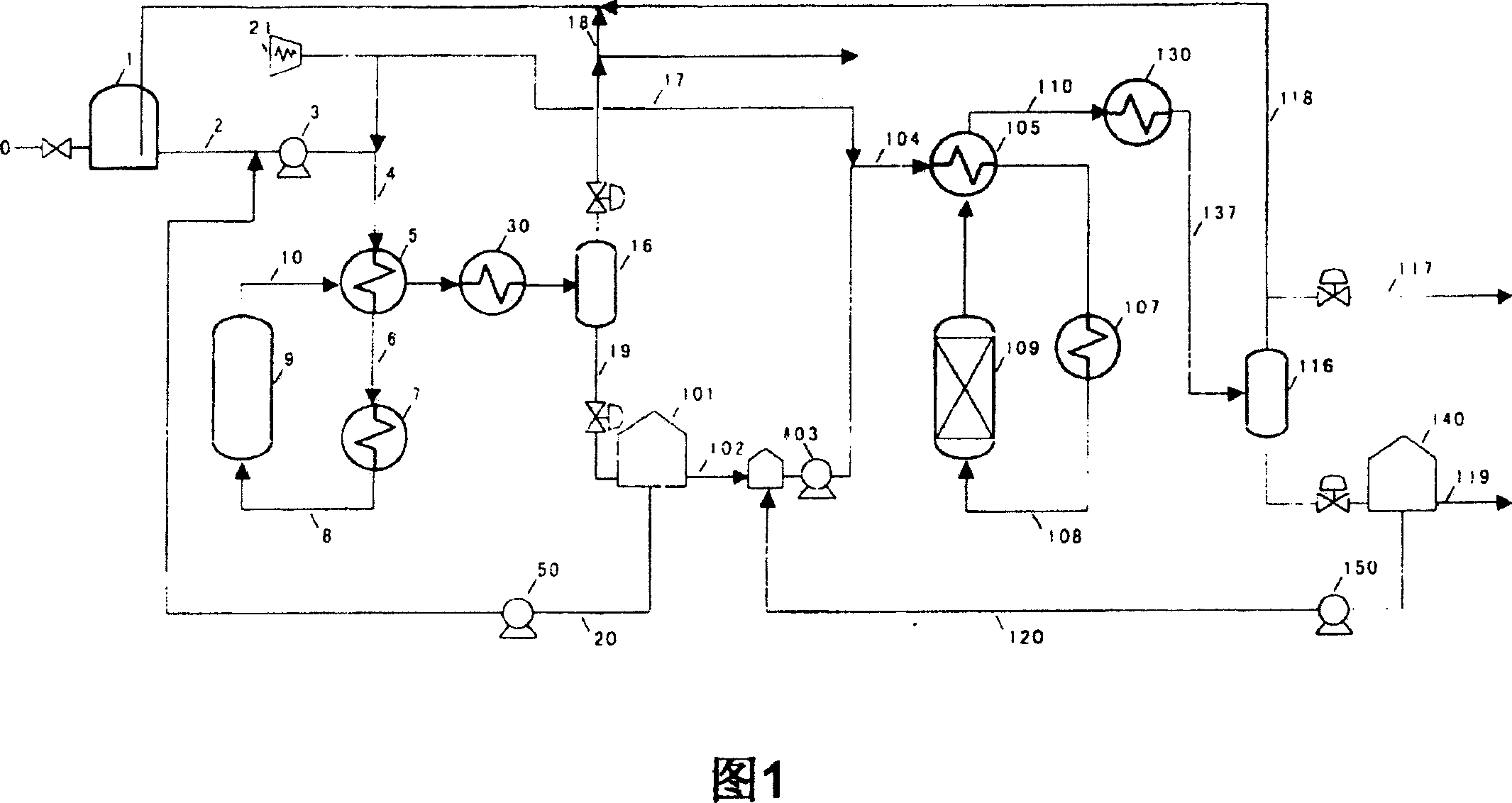

[0094] Wastewater (alkaline wastewater containing nitrogen-containing compounds, organic substances, and inorganic substances in high concentrations) generated in petroleum refineries having the properties shown in Table 1 was treated according to the flow shown in FIG. 1 .

[0095] pH

14.5

BOD

12.6g / L

CODcr

275g / L

TOC

100g / L

NH 3 -N

52mg / L

54g / L

S(SO 4 )

10g / L (30g / L)

CL

5.4g / L

[0096] The CODcr concentration of the raw wastewater is 275g / L, the raw wastewater treatment capacity is 105kg / hr, and the air volume is 125Nm 3 / hr. From the treatment water tank 101, the wet oxidation treatment water and the raw waste water were circulated and mixed at a circulation rate of 347 kg / hr. This circulation amount is equivalent to about 3.3 times of the original wastewater treatment amount.

[0097] The outlet temperature of the wet oxidation reactor 9 is 275° C., and the press...

Embodiment 2

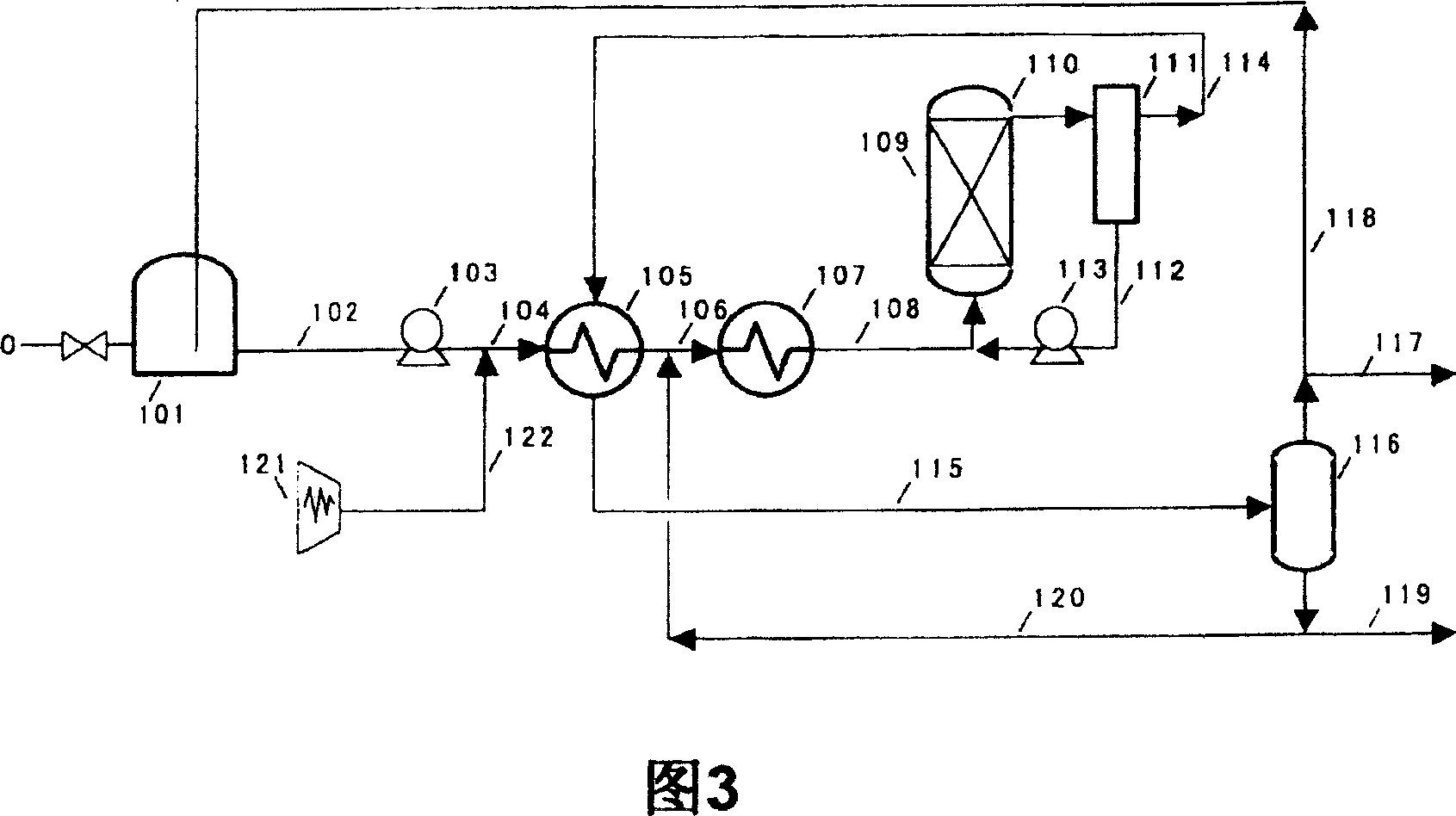

[0107] The waste water (alkaline waste water containing nitrogen-containing compounds, organic matter and inorganic matter in a high concentration) produced in a petroleum refining plant used in Example 1 was diluted so that the CODcr concentration was 100 g / L and the TOC concentration was 36 g / L. L, add ammonia water to the wastewater to make NH 3 -N concentration is 3000mg / L. According to the process shown in Figure 3, the waste water was treated.

[0108] The raw wastewater treatment capacity is 20.8kg / hr, and the air volume is 7.7Nm 3 / hr. With a circulation rate of 31kg / hr, the wet catalytic oxidation treatment water from the treatment water tank is circulated and mixed with the raw wastewater. This circulation amount is equivalent to about 1.5 times of the original wastewater treatment amount. The reaction time is 0.75hr.

[0109] The treated water quality is, CODcr: 100mg / L, TOC: 35mg / L, NH 3 -N: <1 mg / L.

[0110] A spherical catalyst (approximately 5 mm in diame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com