A Method for Determining the Maximum Deflection of Large Corner Round Thin Films under Uniform Loads

A technology of uniform load and maximum deflection, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of determining the maximum deflection of the round film, the transverse load q cannot be too large, and the design and application of precision measuring instruments cannot be used. , to achieve the effect of eliminating calculation errors and convenient design and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

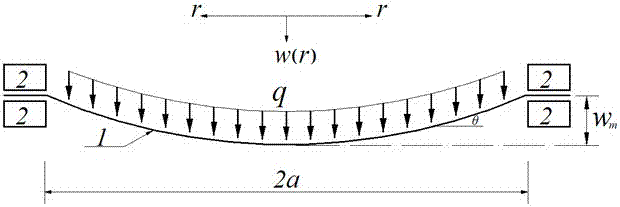

[0017] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0018] like figure 1 As shown, use a clamping device with an inner radius a=20mm to fix and clamp the rubber film without prestress with Young's elastic modulus E=7.84MPa, Poisson's ratio ν=0.47, and thickness h=0.06mm to form A circular film structure with a radius a=20mm fixed and clamped around the periphery, applies a uniform load q to the circular film laterally, and allows the applied uniform load q to slowly increase from 0.01MPa to 0.1MPa, using the method provided by the present invention method, the maximum deflection w of the circular rubber film under the action of transverse uniform load q can be determined m ,As shown in Table 1.

[0019] In table 1, the data of rotation angle θ is the film rotation angle value (degree) at r=10mm place, in addition, in order to reflect the error that adopts the small rotation angle hypothesis of fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com