Reverse jacking mechanism

A technology of reverse jacking mechanism and ejector rod, which is applied in the field of die-casting molds, can solve the problems that the mold without seat plate cannot realize the function of the reverse jacking mechanism, the thickness of the seat plate is large, and affects the strength of the mold, so as to reduce the structure of the fixed mold seat plate, The effect of stable mechanism and convenient design and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

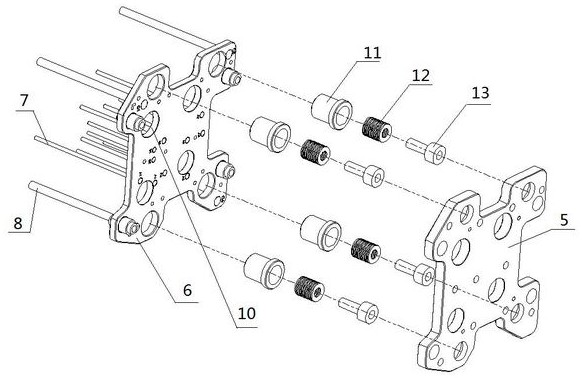

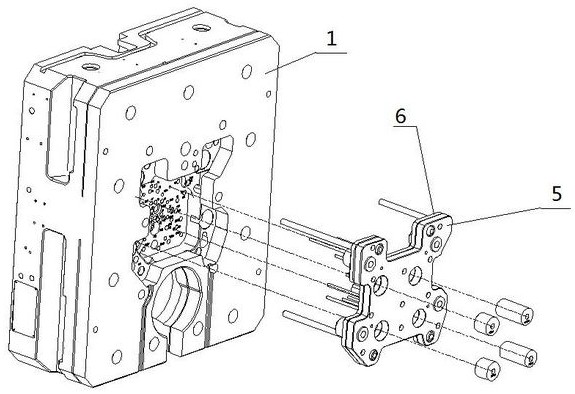

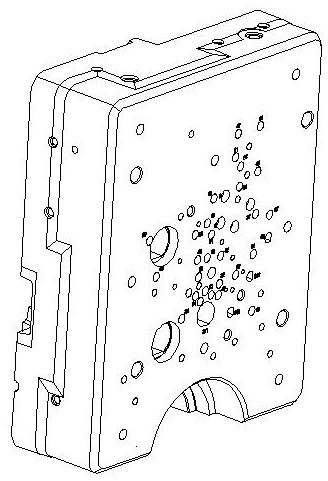

[0048] Such as Figure 1-7As shown, the reverse ejection mechanism is characterized in that it includes: reverse ejector push plate 5, reverse ejector rod fixed plate 6, reverse ejector rod 7, reverse ejector assembly, guide assembly, reset rod 8, fixed mold frame 1 and fixed mold Core 2, the upper end surface of the reverse ejector rod fixing plate 6 is provided with an anti ejector push plate 5, and the corresponding position of the reverse ejector push plate 5 and the reverse ejector rod fixed plate 6 is provided with a mounting hole for installing the reverse ejector assembly, The anti-jack assembly is arranged in the installation hole; the anti-jack push plate 5 and the anti-jack rod fixed plate 6 corresponding positions within the installation hole are provided with a guide hole for installing the guide assembly, and the guide assembly is arranged in the guide hole; the described The reverse ejector rod fixed plate 6 middle area is provided with the reverse ejector rod 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com