Power socket

A power socket and socket panel technology, applied in the direction of circuits, electrical components, coupling devices, etc., can solve the problems of increased space pressure, different sizes, shapes, and inability to use three holes, etc., to achieve extended service life, reasonable structure, The effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

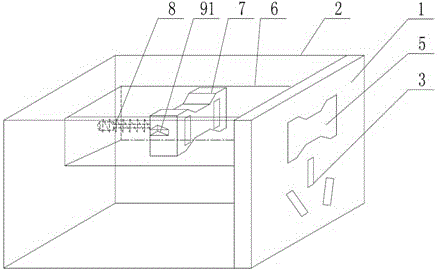

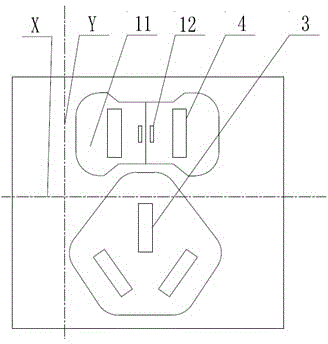

Embodiment 1

[0027] A power socket disclosed in this embodiment, as attached Figure 1-2 As shown, it includes a socket panel 1 and a matching slot 2. The socket panel 1 is provided with three holes 3 and two holes 4. The socket panel 1 corresponding to the two holes 4 can slide to both sides to form an opening. 5. Specifically, the backs of the socket panels 1 on both sides of the opening 5 are respectively provided with transverse chutes, that is, in the X-axis direction, and a slidable and automatic resettable panel 11 is respectively clamped in the chutes, and the two The panels 11 are respectively provided with a jack, and when the two panels 11 are in the closed state, the jacks on both constitute the two holes 4; in order to facilitate the sliding of the panels 11, the panels 11 The upper surface is also provided with protrusions 12 or anti-slip sheets matching with fingers, preferably in this embodiment, the protrusions 12 are arranged on the panels, and the protrusions 12 are loca...

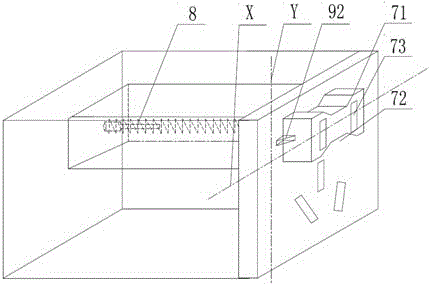

Embodiment 2

[0034] This embodiment is similar to the overall structure and working process of Embodiment 1, and its difference is: as attached Figure 4 As shown, the telescopic mechanism 8 only includes a telescopic spring with one end fixed at the bottom of the concave conversion head 7 and the other end fixed at the bottom of the fixed groove 6, and the telescopic spring is fixed in the fixed groove 6 It is in a compressed state, and the magnetic touch switch is subtracted; at the same time, the limit mechanism includes limit grooves 93 respectively arranged at the ends of the two side walls of the concave conversion head 7, and the limit grooves 93 and The slidable panels 11 match.

[0035] When using the power socket in this embodiment, the user opens the panel 11 in the same way. When the user opens the panel 11, the concave conversion head 7 protrudes upwards under the reaction force of the telescopic spring in the compressed state, until When the height of the limiting groove 93 ...

Embodiment 3

[0037] The concave conversion head 6 described in this implementation is a device independent of the socket, and its internal structure is consistent with all kinds of socket conversion heads in the known prior art, but its specific shape is the same as that in Embodiments 1 and 2. The description is the same; when in use, you can directly insert the concave-shaped rotating head 6 into the two holes of the socket, and then plug in the two-hole plug of the electrical equipment to use; when not in use, unplug it from the socket for storage That's it.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com