Automatic bamboo chip threading machine

A technology for automatic threading and bamboo strips, which is applied in the field of needle threading machines and can solve problems such as not being able to thread bamboo strips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

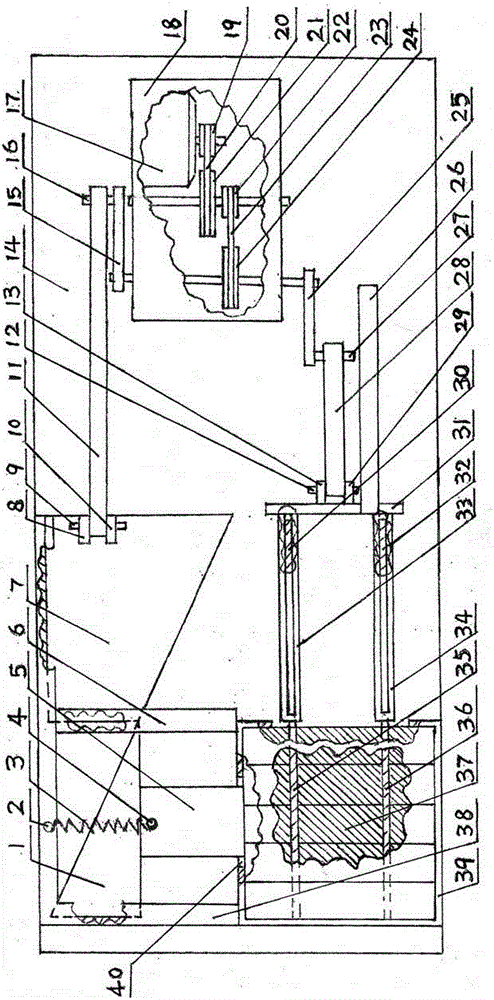

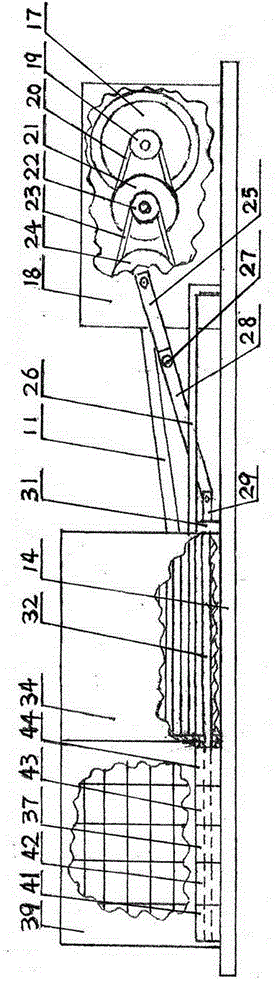

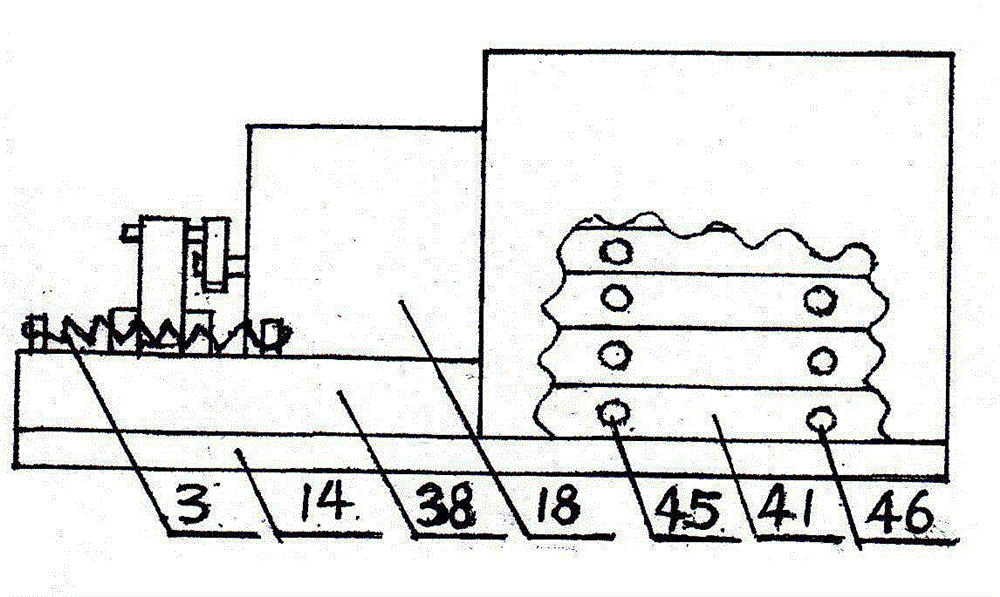

[0012] refer to Figure 1~4 , the bamboo needle threading machine consists of a triangular movable top plate 1, a first helical spring fixing nail 2, a second helical spring fixing nail 4, a helical spring 3, a first top plate 5, a second top plate 31, a bar-shaped pressing plate 6, and a trapezoidal movable Top plate 7, first splint 8, second splint 10, third splint 13, fourth splint 29, first link shaft 9, second link shaft 12, first link 11, second link 28, bottom plate 14, the first lever 15, the second lever 25, the first lever shaft 16, the second lever shaft 27, the motor 17, the pulley box 18, the first pulley 19, the second pulley 21, the third pulley 22, The fourth belt pulley 24, the first belt 20, the second belt 23, the L-shaped stop plate 26, the first push rod 30, the second push rod 32, the first bamboo chip needle case 33, the second bamboo chip needle case 34, The first pierces the bamboo slice needle 35, the second pierces the bamboo slice needle 36, the L-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com