Rotatablely positioning cable insulating layer color matching material supply equipment

An insulating layer and color matching technology, applied in the field of color matching material supply equipment, can solve the problems of inability to accurately locate the extrusion head, inconvenience, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

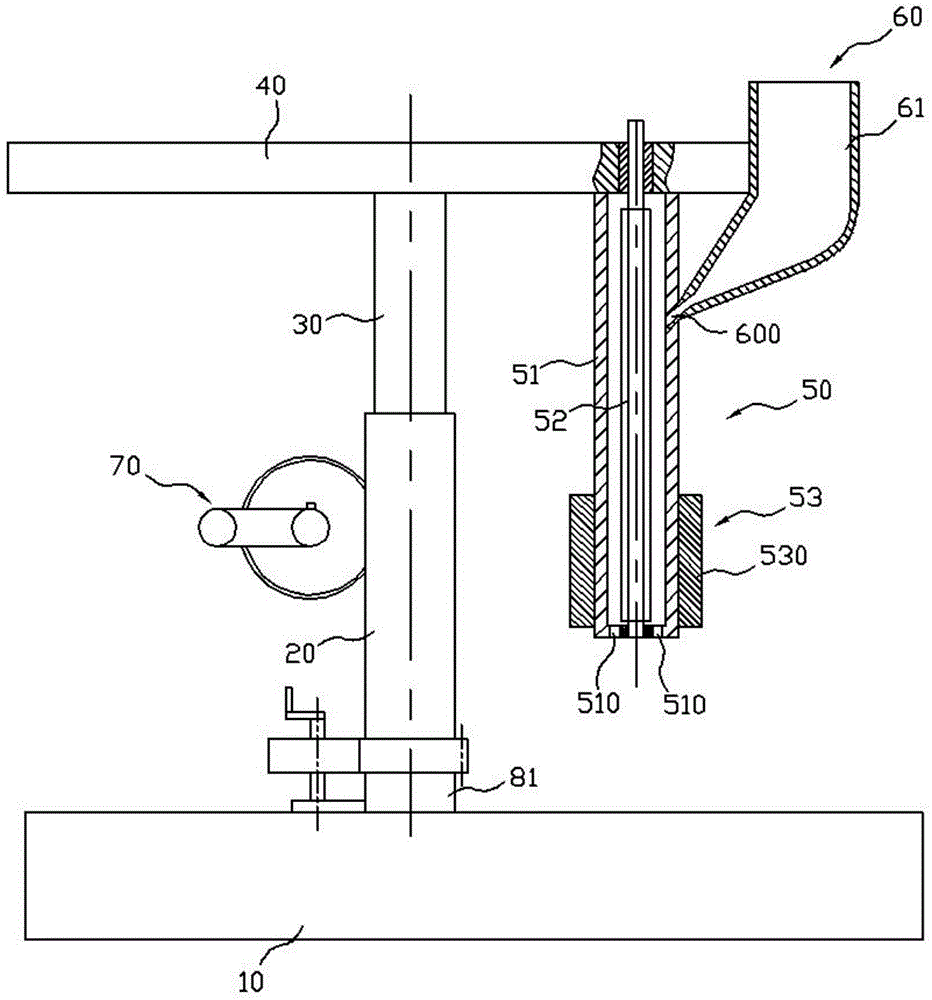

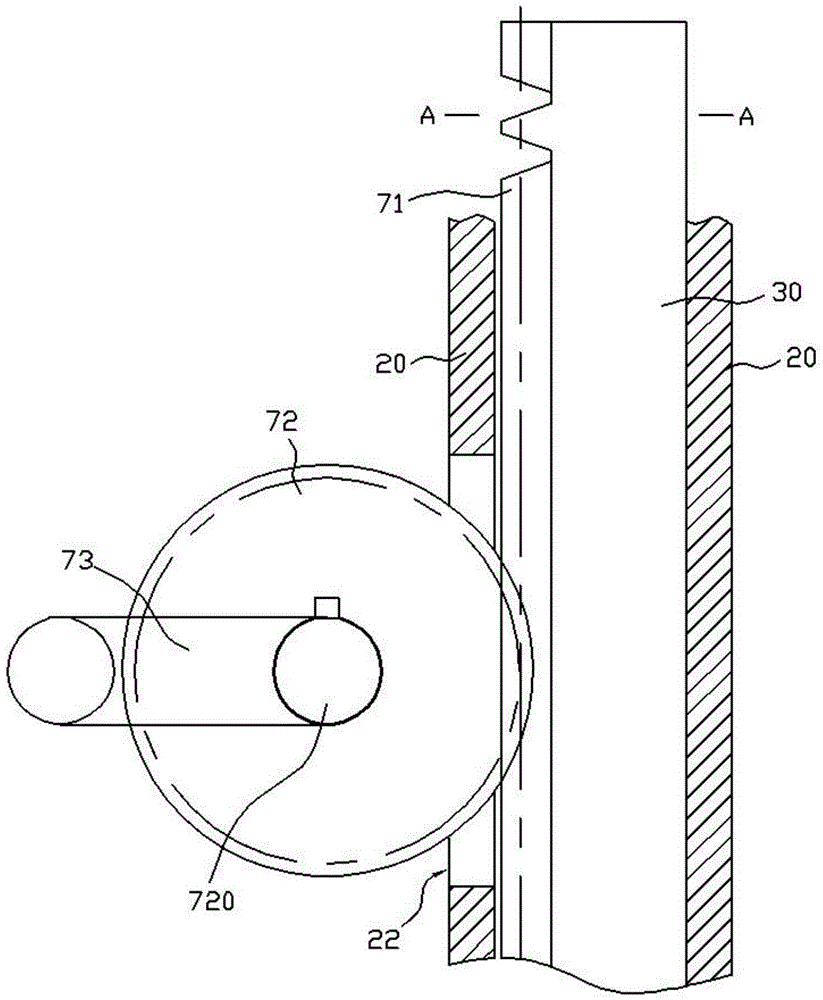

[0036] like figure 1 , a rotatably positioned cable insulation layer coloring material supply equipment, including a base 10, a column 20, a lifting column 30, a beam 40, a paint extrusion device 50, and a paint supply device 60.

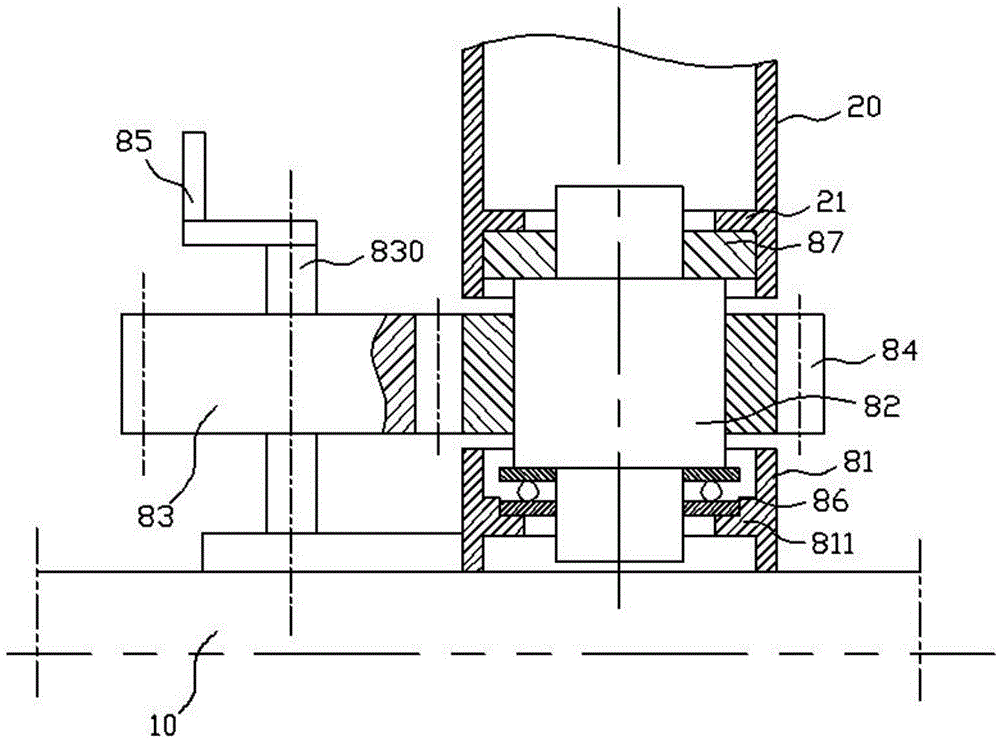

[0037] combine figure 1 , figure 2 , the base 10 is fixed with a mounting seat 81, the mounting seat 81 is pivotally connected with a rotating shaft 82, the axis line of the rotating shaft 82 is vertical, and the bottom end of the rotating shaft 82 is pivotally connected to the installation On the seat 81 , the top end of the rotating shaft 82 is fixedly connected with the bottom end of the column 20 .

[0038] Among them, such as figure 2 , the mounting seat 81 is hollow, the hollow part of the mounting seat 81 has a circular cross section, and the inner side wall of the mounting seat 81 is provided with an inwardly protruding flange 811; the bottom end of the rotating shaft 82 passes through a thrust ball bearing 86 is pivotally connected to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com