A kind of aromatic polyester containing triphenylamine and its preparation method and application

A technology of aromatic polyester and triphenylamine, which is applied in the direction of chemical instruments and methods, color-changing fluorescent materials, etc., can solve the problems of easy crystallization and low solubility of polyester, and achieve a good reversible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

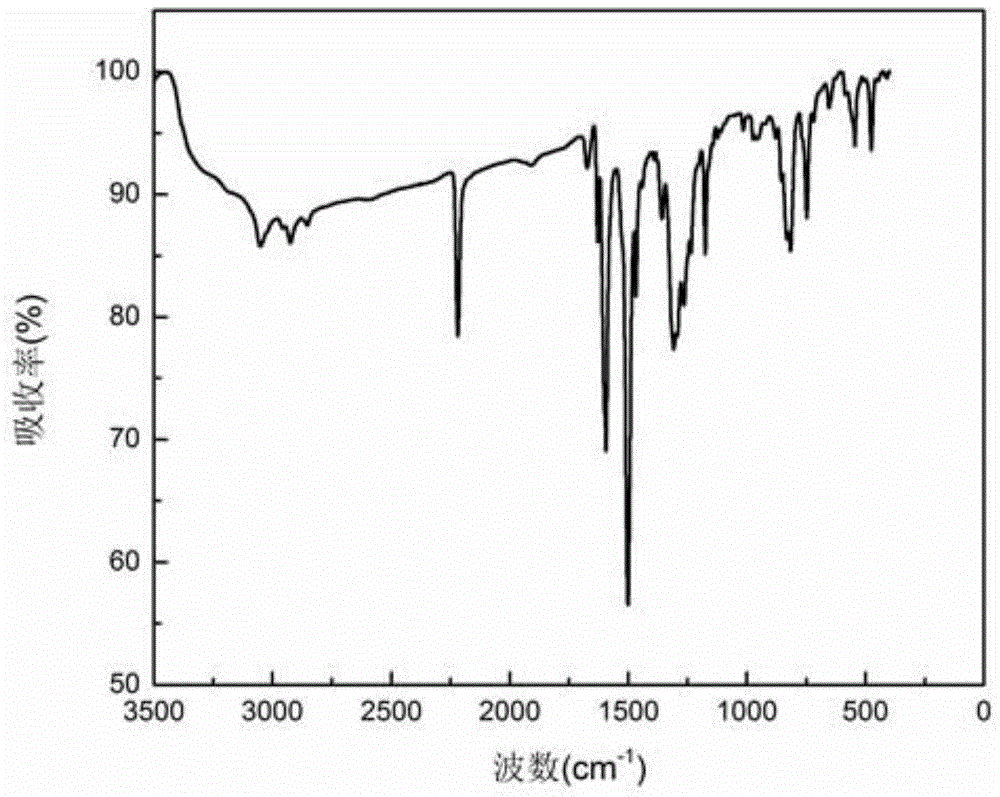

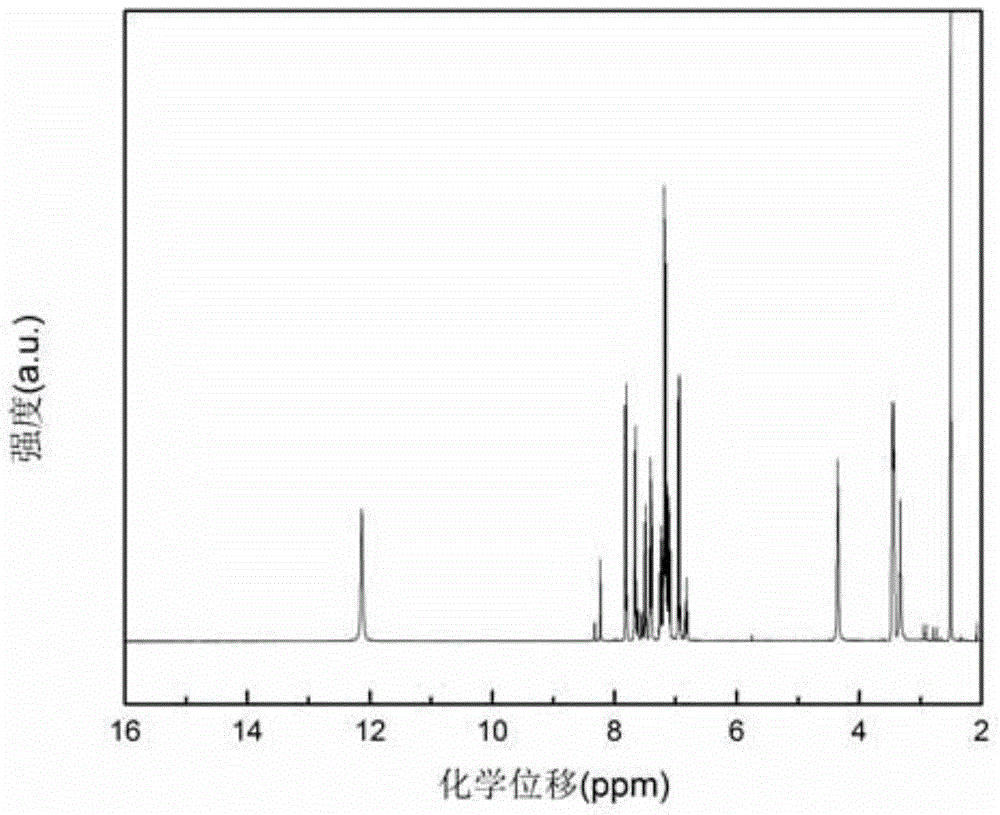

[0052] Specific implementation mode one: the present implementation mode is a structural formula of an aromatic polyester containing triphenylamine: Wherein, the R is The value of n is 1≤n≤100, and n is an integer.

[0053] The advantage of this implementation mode:

[0054] 1. The aromatic polyester containing triphenylamine prepared in this embodiment overcomes the shortcomings that polyarylates were difficult to dissolve in general organic solvents;

[0055] 2. Dissolving the aromatic polyester containing triphenylamine in this embodiment in N,N'-dimethylacetamide, N,N'-dimethylformamide, N-methylpyrrolidone and dimethylmethylene in sulfone; the aromatic polyester solution containing triphenylamine was dissolved in dimethyl sulfoxide to obtain the aromatic polyester solution containing triphenylamine; the aromatic polyester solution containing triphenylamine was spin-coated on ITO glass as Working electrode, saturated calomel electrode as reference electrode, platinu...

specific Embodiment approach 2

[0058] Specific embodiment two: the present embodiment is a kind of preparation method of the aromatic polyester containing triphenylamine is completed according to the following steps:

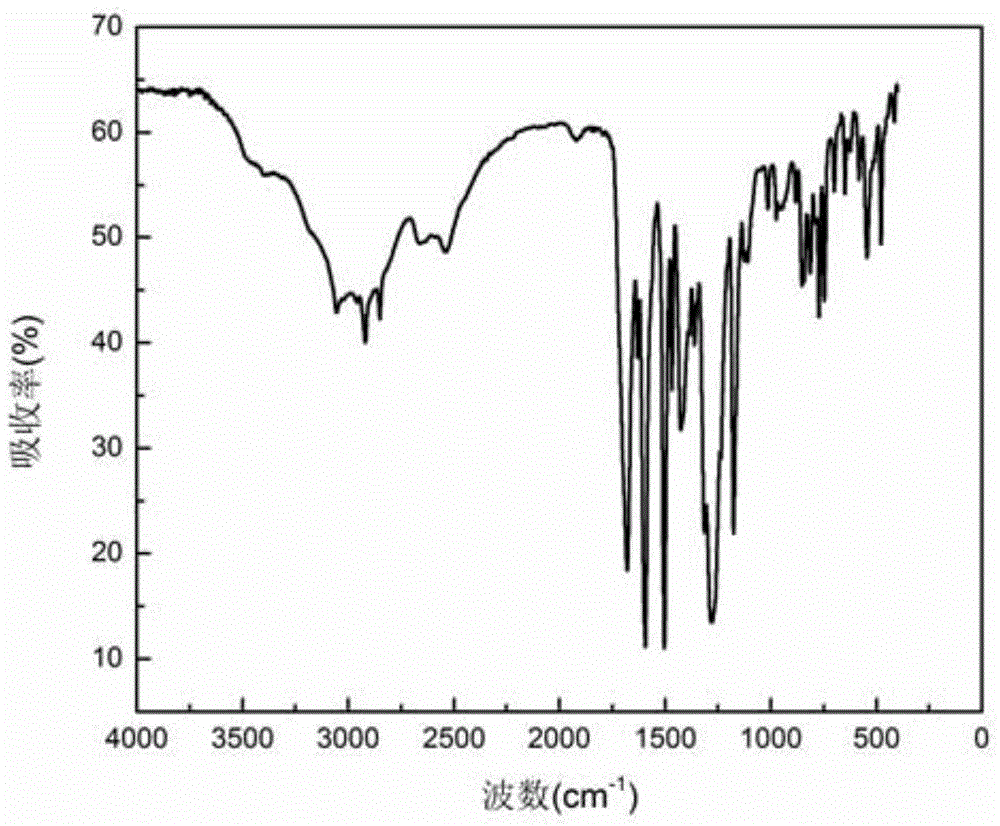

[0059] 1. Preparation of N,N'-bis(β-naphthyl)-N,N'-bis(4-carboxybenzene)-p-phenylenediamine monomer:

[0060] ①. Under a nitrogen atmosphere, dissolve N,N′-bis(β-naphthyl)-p-phenylenediamine in anhydrous N,N-dimethylformamide, then add p-fluorobenzonitrile and sodium hydride, and then React at a temperature of 120°C to 130°C for 15h to 20h, then use distilled water at a temperature of 0°C to 5°C to precipitate the reactant A, then perform suction filtration on the reactant A, discard the filtrate, and then filter the reactant A at a temperature of 30°C Dry at ~35°C for 24h to 30h to obtain the dried reactant A; use acetone to recrystallize the dried reactant A, and then dry at a temperature of 30°C to 35°C for 6h to 8h to obtain the dinitrile group monomer;

[0061] The volume ratio of the ...

specific Embodiment approach 3

[0081] Specific embodiment three: the difference between this embodiment and specific embodiment two is: N,N'-bis(β-naphthyl)-N,N'-bis(4-carboxybenzene) described in step ② The structural formula of p-phenylenediamine monomer is Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com