A lock cylinder with a limit post

A technology of limit posts and lock cylinders, which is applied to locks with rotating keys, construction locks, cylinder pin locks, etc., can solve the problems of poor anti-theft performance, high cost, and unsuitability for popularization and use of A-level anti-theft locks. The production cost is low, the effect of improving the anti-theft level and avoiding financial loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

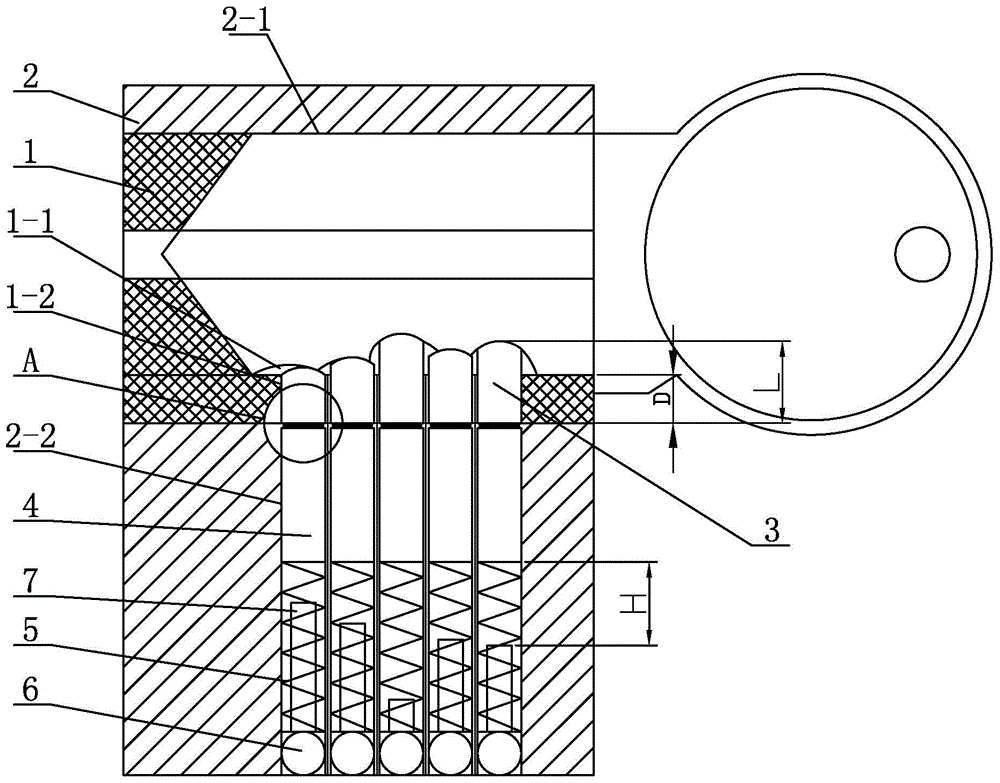

[0007] Specific implementation mode one: combine figure 1 and figure 2 Describe this embodiment, a lock cylinder with a limit post described in this embodiment includes an inner lock cylinder 1 and an outer lock cylinder 2, and the inner lock cylinder 1 is inserted into the jack 2-1 on the upper part of the outer lock cylinder 2. The embodiment also includes a plurality of upper cylinders 3, a plurality of lower cylinders 4, a plurality of springs 5, a plurality of sealing beads 6 and a plurality of limit posts 7, and the lower hole wall of the keyhole 1-1 of the inner lock core 1 A plurality of first through holes 1-2 are arranged side by side from left to right on the top, and a plurality of second through holes 2-2 are arranged side by side from left to right on the lower hole wall of the socket 2-1 of the lock cylinder 2. , a plurality of first through holes 1-2 communicate with a plurality of second through holes 2-2 in one-to-one correspondence, each first through hole...

specific Embodiment approach 2

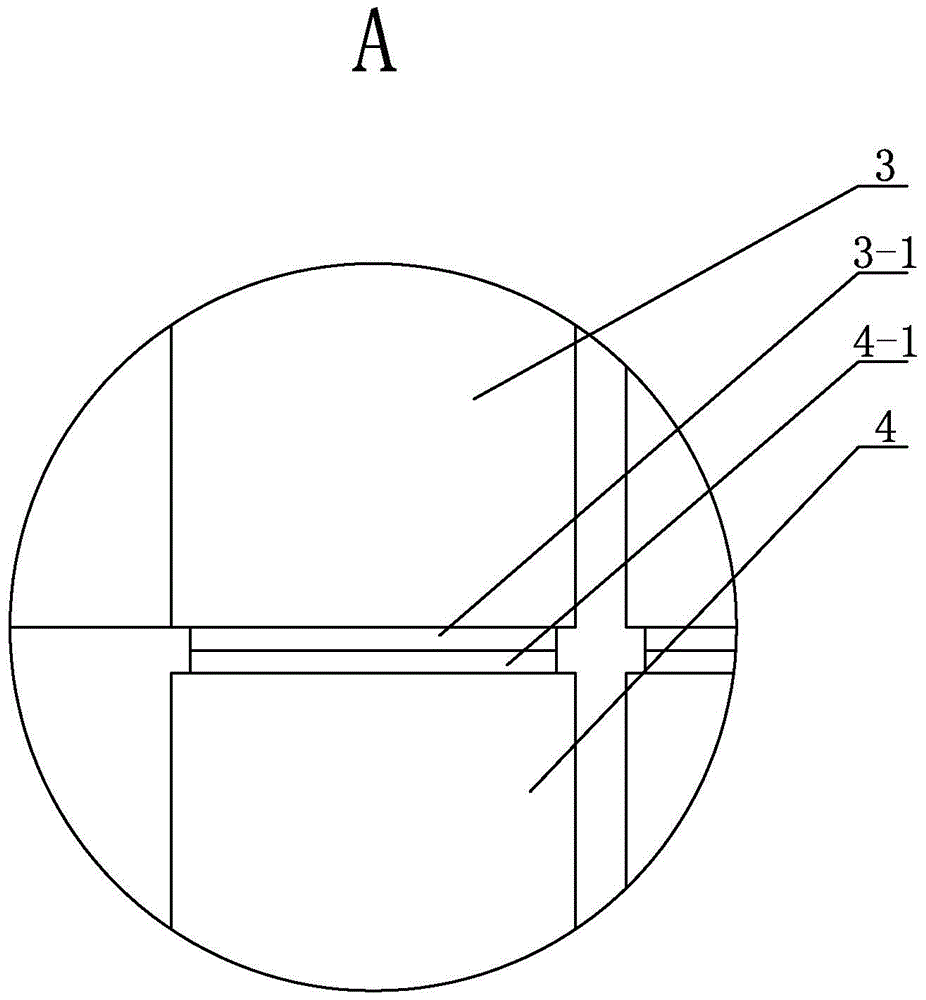

[0008] Specific implementation mode two: combination figure 1 and figure 2 To illustrate this embodiment, the lower end surface of each upper cylinder 3 of the lock core with a limit cylinder described in this embodiment is provided with a first boss 3-1, and the upper end surface of each lower cylinder 4 is provided with a The second bosses 4-1, each first boss 3-1 is in contact with a corresponding second boss 4-1.

[0009] The technical effect of this embodiment is: so set up, when the thief picks the lock, there will be misalignment between the upper cylinder 3 and the lower cylinder 4, and they will be separated from each other. Misalignment, the first boss 3-1 and the second boss 4-1 are mutually locked, preventing the upper cylinder 3 from detaching from the first through hole 1-2, effectively preventing the thief from picking the lock successfully. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0010] Specific implementation mode three: combination figure 1 and figure 2 Describe this embodiment, each upper cylinder 3 of a lock core with a limit cylinder described in this embodiment is an upper cylinder 3 made of a magnet, and each lower cylinder 4 is a lower cylinder made of ferrous metal 4.

[0011] The technical effect of this embodiment is: such arrangement prevents the upper cylinder 3 from being separated from the lower cylinder 4 when the thief picks the lock by the pop-off method, and effectively improves the anti-theft level of the lock cylinder. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com