A briquetting mechanism of an abrasive belt grinder

A grinding machine and pressing mechanism technology, applied in abrasive belt grinders, grinders, grinding/polishing equipment, etc., can solve the problems of reducing the friction effect of the abrasive belt, loosening the tension of the abrasive belt, affecting the grinding effect, etc., and achieves a simple structure. , Improve the pressing friction, improve the effect of grinding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

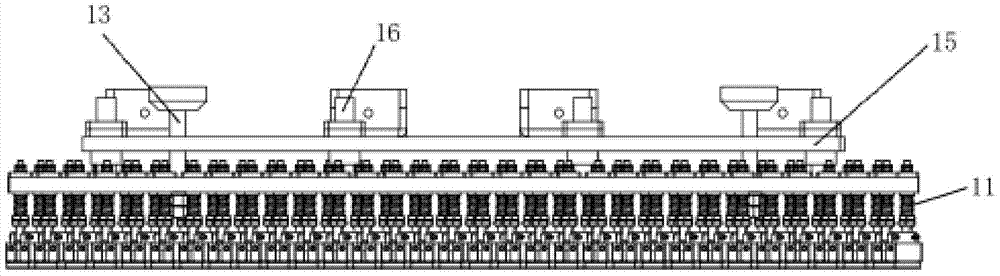

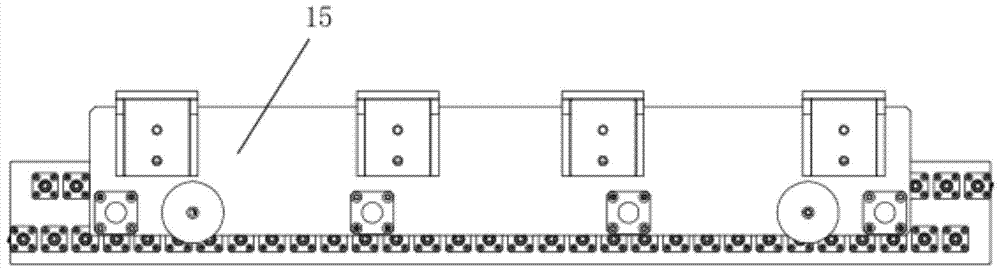

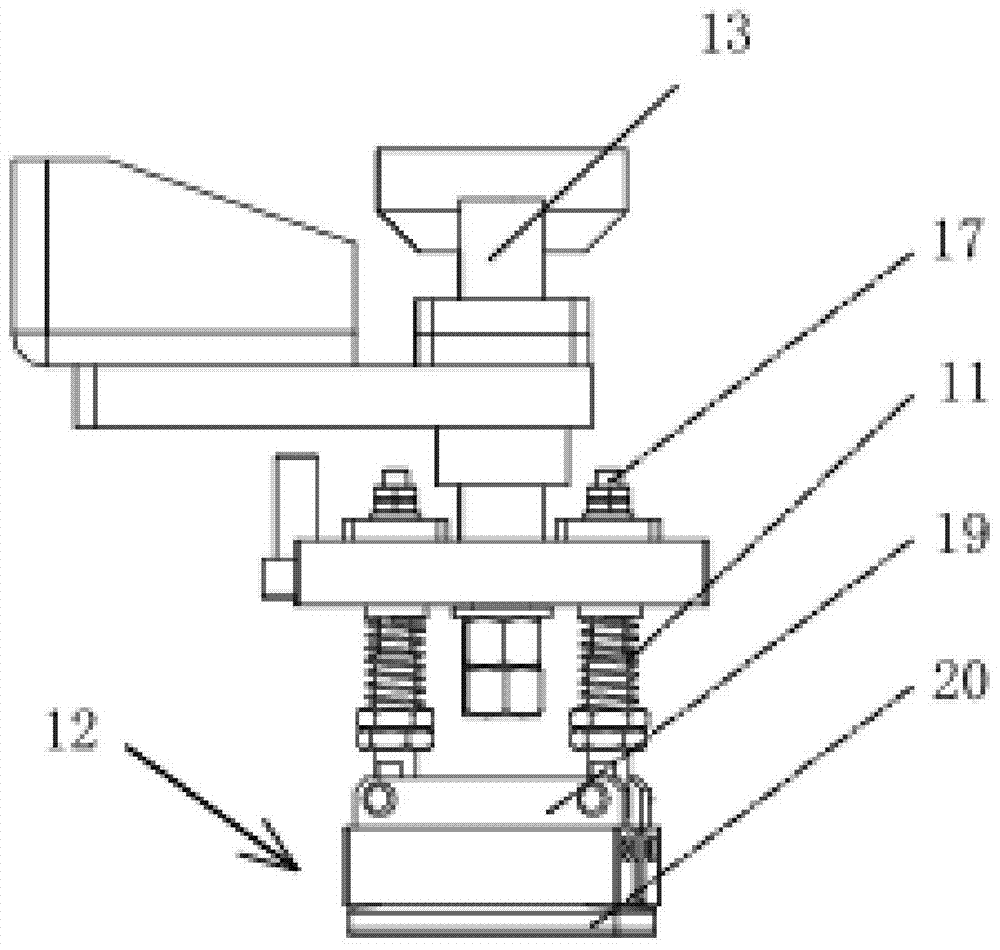

[0017] Example: see Figure 1-6 As shown, a briquetting mechanism of an abrasive belt grinder, the abrasive belt grinder includes a bracket 1 and an abrasive belt grinding driving wheel 2 arranged on the bracket 1, an abrasive belt grinding driven wheel 3, and an abrasive belt grinding deviation adjustment Wheel 4, abrasive belt tensioning cylinder 5 and abrasive belt lifting stepper motor 6, described abrasive belt grinding driving wheel 2 is driven to rotate through a motor 7, and an abrasive belt 8 is wound around the described abrasive belt grinding driving wheel 2, abrasive belt On the belt grinding driven wheel 3 and the abrasive belt grinding deflection wheel 4, the output end of the abrasive belt tensioning cylinder 5 acts on the abrasive belt 8 to tension the abrasive belt 8, and the abrasive belt lifting stepping motor 6 The output end of the output end acts on the abrasive belt 8 to lift and lower the abrasive belt 8 as a whole. The briquetting mechanism includes a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com