A belt grinder

A grinding machine and abrasive belt technology, which is applied in the direction of abrasive belt grinders, grinding machines, grinding/polishing equipment, etc., can solve the problems of reduced abrasive belt friction effect, affecting grinding effect, loosening of abrasive belt tension, etc., and achieves simple structure, Improve the grinding effect and improve the effect of pressing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

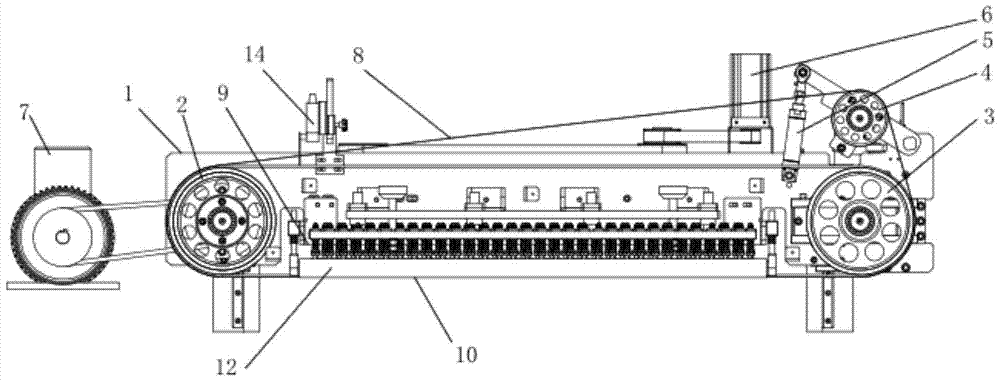

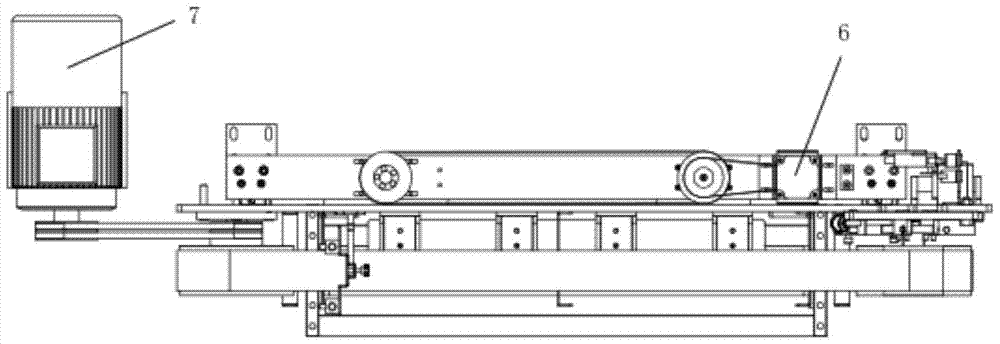

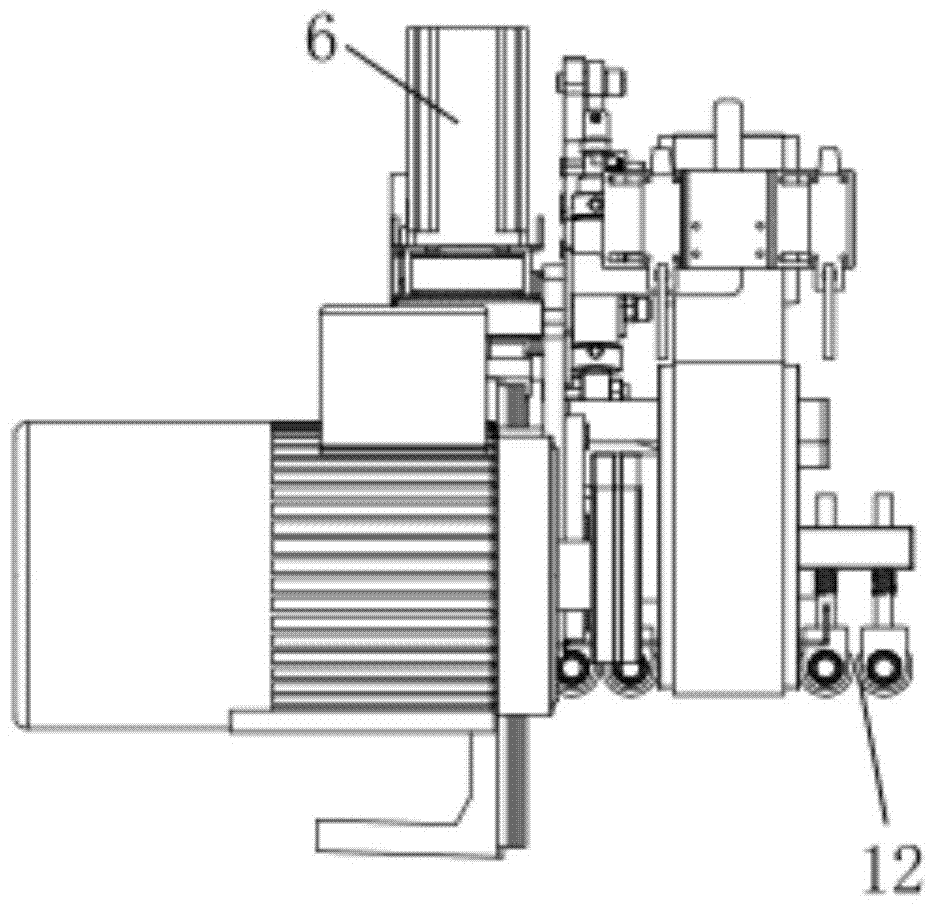

[0017] Example: see Figure 1-3 As shown, an abrasive belt grinder includes a bracket 1 and an abrasive belt grinding driving wheel 2 located on the bracket 1, an abrasive belt grinding driven wheel 3, an abrasive belt grinding deflection wheel 4, an abrasive belt tensioning cylinder 5 and Abrasive belt lifting stepping motor 6, described abrasive belt grinding driving wheel 2 drives rotation through a motor 7, and an abrasive belt 8 is wound around described abrasive belt grinding driving wheel 2, abrasive belt grinding driven wheel 3 and abrasive belt grinding adjustment On the bias wheel 4, the output end of the abrasive belt tensioning cylinder 5 acts on the abrasive belt 8 to tension the abrasive belt 8, and the output end of the abrasive belt lifting stepping motor 6 acts on the abrasive belt 8, In order to lift and lower the abrasive belt 8 as a whole, a horizontal plate 9 is fixedly connected to the support 1, and the abrasive belt 8 has a friction belt 10 for rubbing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com