A PTFE rubber-plastic composite self-lubricating O-ring

A teflon, O-ring technology, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of easy wear, high friction coefficient of pure rubber elastomer, difficult to withstand the dynamic sealing requirements of moving shafts, etc. , to maintain the balance of elasticity index, elasticity and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

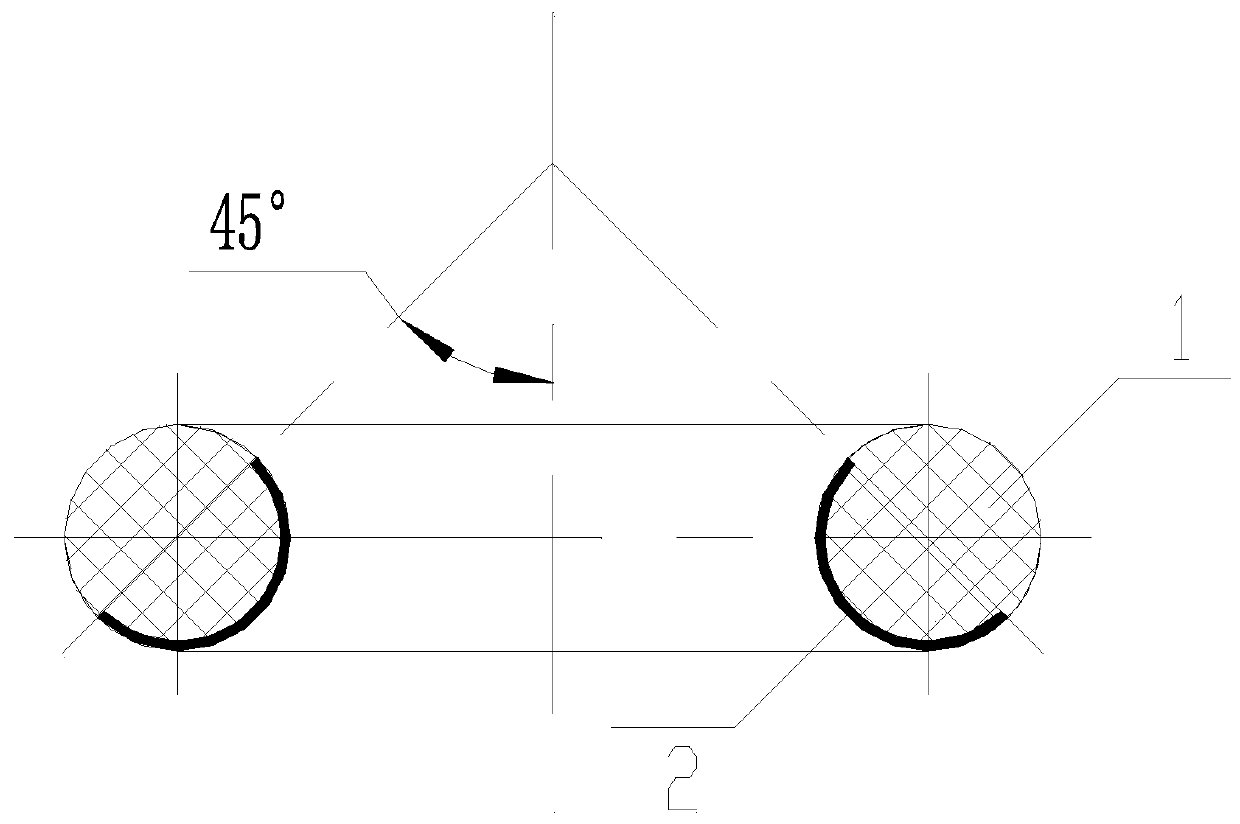

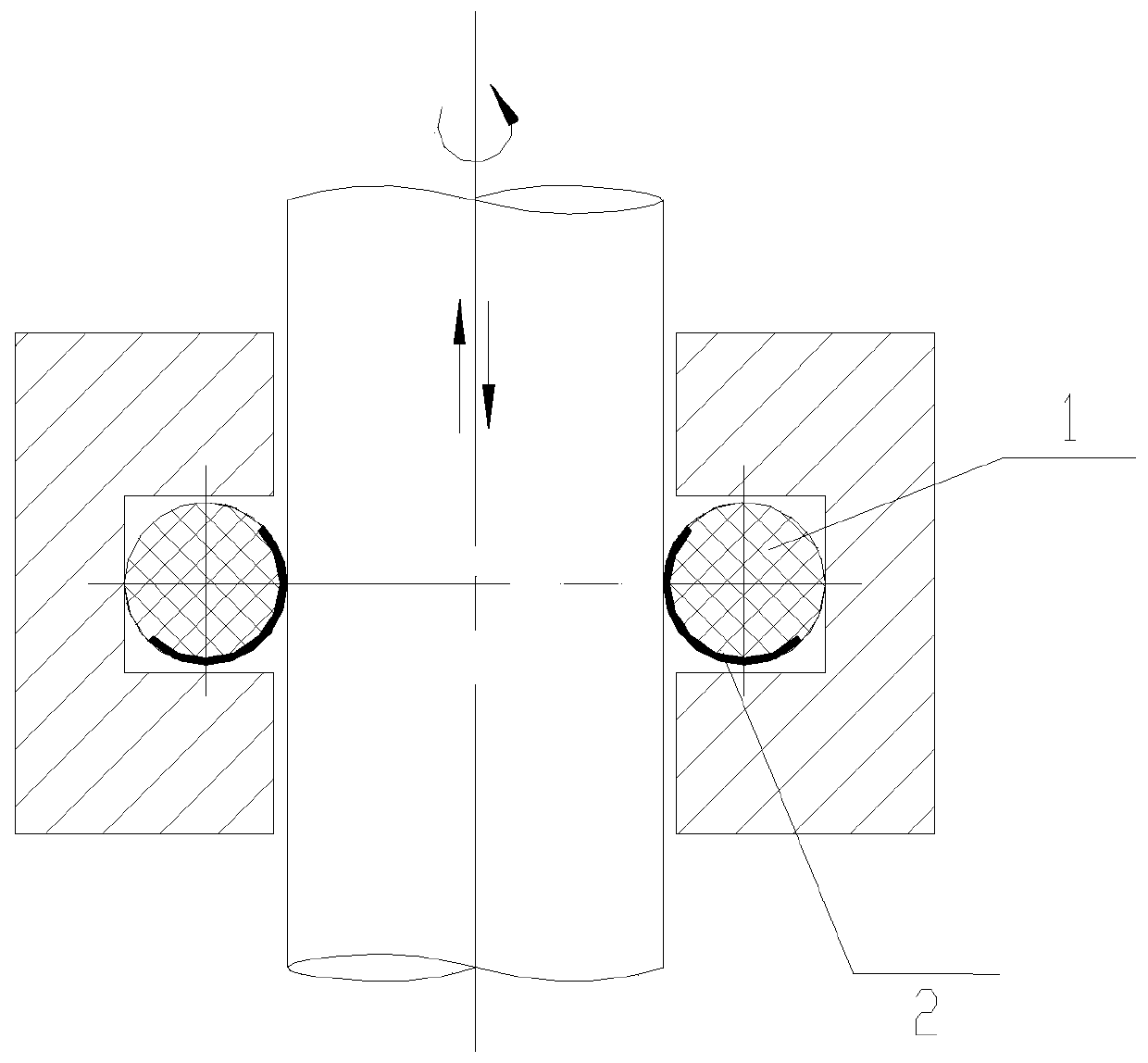

[0017] Such as figure 1 and figure 2 As shown, it is a polytetrafluoroethylene rubber-plastic composite self-lubricating O-ring used as a shaft, which includes a ring-shaped sealing ring body, which is composed of rubber elastic body 1 and compounded on the rubber elastic body 1 The ring-shaped polytetrafluoroethylene covering body 2 on the ring-shaped working surface is composed of. The thickness of the polytetrafluoroethylene covering body 2 is 0.05mm-2mm, the inner diameter specification of the polytetrafluoroethylene rubber-plastic composite self-lubricating O-ring is Φ3mm-Φ1000mm, and the section specification is Φ2mm-Φ100mm. The polytetrafluoroethylene covering body 2 has a semicircular cross section and is a layer of semicircular thin slices. On the cross section of the sealing ring body, the line between the two ends of the polytetrafluoroethylene covering body 2 forms an included angle of 45° with the plumb line. The polytetrafluoroethylene covering body 2 is loca...

Embodiment 2

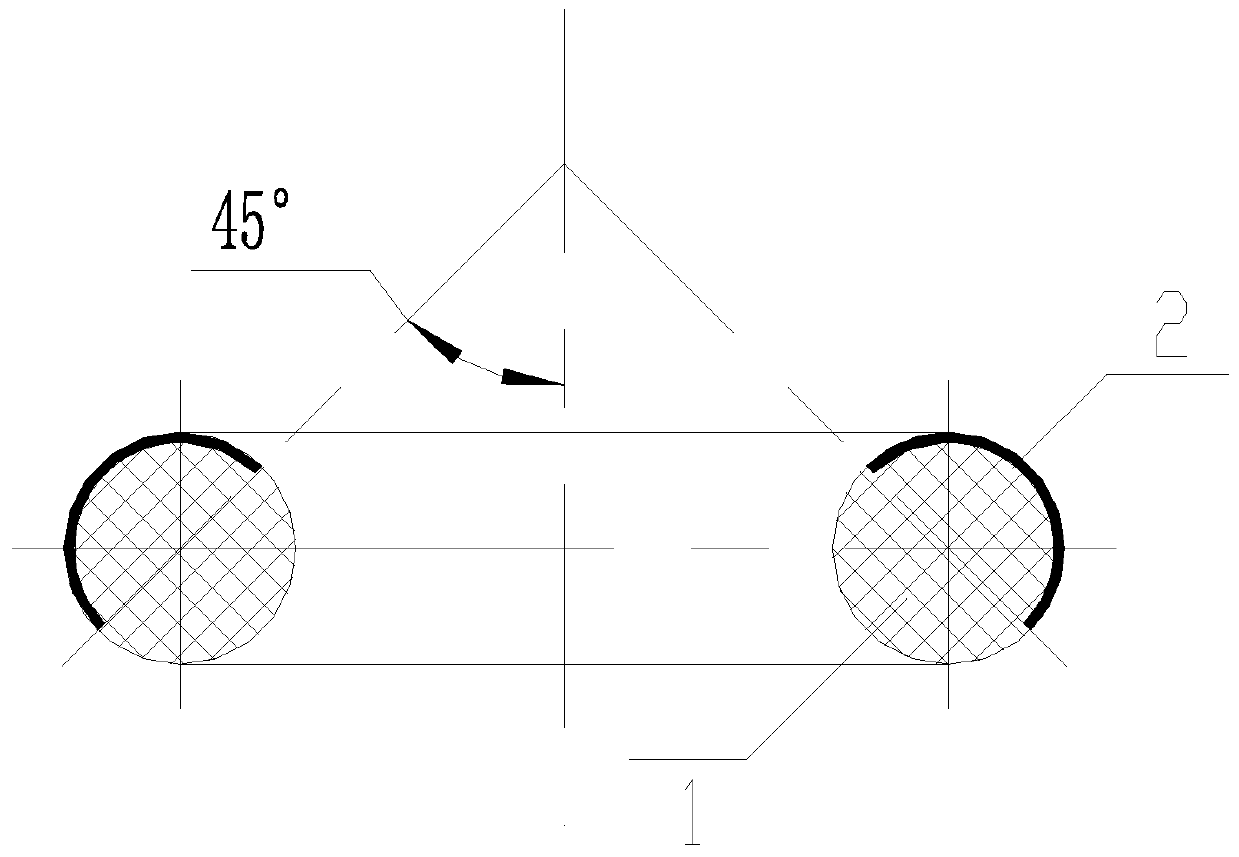

[0019] Such as image 3 and Figure 4 As shown, it is a polytetrafluoroethylene rubber-plastic composite self-lubricating O-ring used as a hole, which includes a ring-shaped sealing ring body, which is composed of rubber elastic body 1 and compounded on the rubber elastic body 1 The ring-shaped polytetrafluoroethylene covering body 2 on the ring-shaped working surface is composed of. The thickness of the polytetrafluoroethylene covering body 2 is 0.05mm-2mm, the inner diameter specification of the polytetrafluoroethylene rubber-plastic composite self-lubricating O-ring is Φ3mm-Φ1000mm, and the section specification is Φ2mm-Φ100mm. The polytetrafluoroethylene covering body 2 has a semicircular cross section and is a layer of semicircular thin slices. On the cross section of the sealing ring body, the line between the two ends of the polytetrafluoroethylene covering body 2 forms an included angle of 45° with the plumb line. The polytetrafluoroethylene covering body 2 is locat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap