A kind of manufacturing method of light conductive wear-resistant material

A technology of wear-resistant material and production method, which is applied in current collectors, electric vehicles, power collectors, etc., can solve the problems of unsatisfactory use and order, and achieve the effects of inhibiting arc ablation resistance, light weight, and high thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

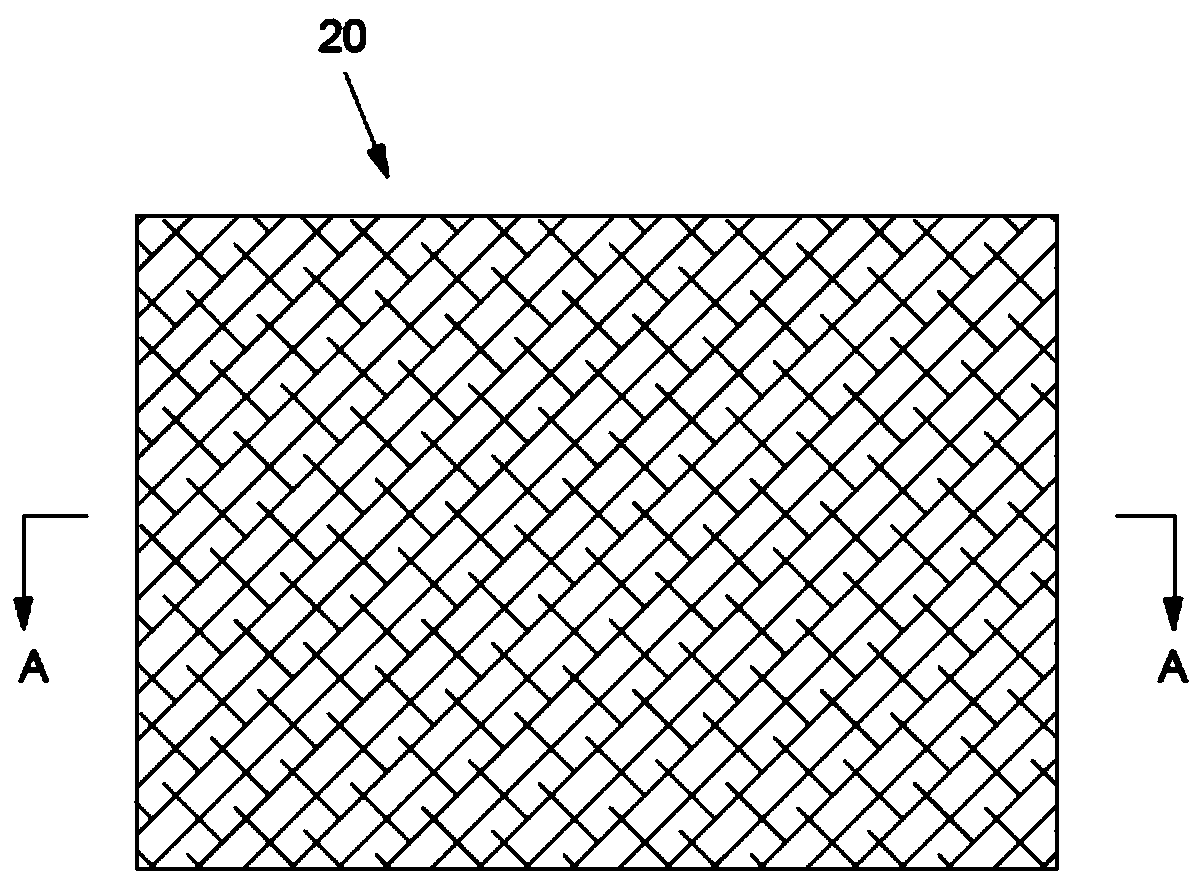

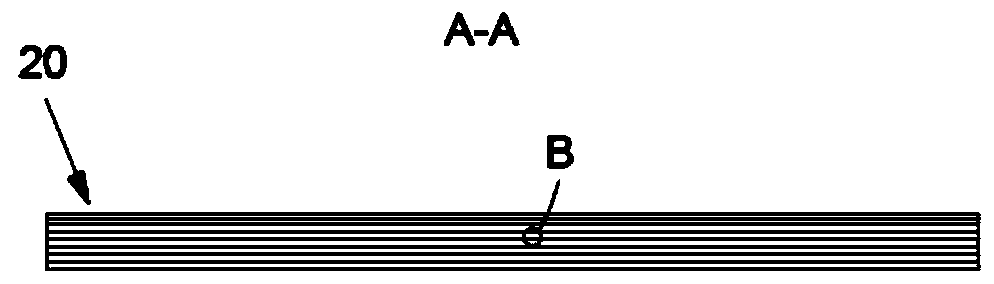

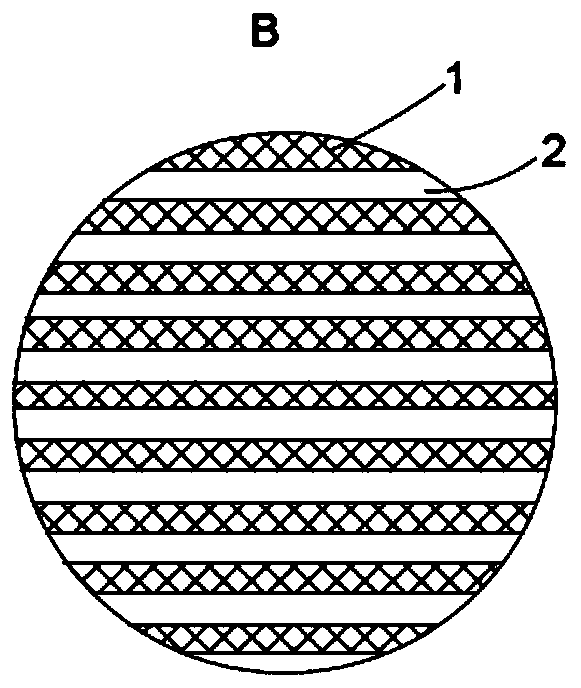

Image

Examples

Embodiment 1

[0030] Taking the production of electrical equipment for electric traction locomotives to obtain electrical energy from the catenary—the pantograph slider as an example, the specific production process is described in detail as follows:

[0031] The first step, making graphene carbon fiber cloth

[0032] In a clean environment, select monomer graphene with a microchip thickness from 0.3nm to 3nm, deposit copper with a particle size of 2nm on the surface of monomer graphene to obtain copper-modified graphene, and the prepared copper-modified graphene Ensure that the mass content of copper is between 0.02% and 3%, and dissolve the prepared copper-modified graphene with a copper content of 0.02%-3% into the raw silk liquid for carbon fiber, and the copper-modified graphene The mass percentage content is between 0.1% and 5%. After conventional spinning and continuous carbon fiber production line processing, carbon fiber short filaments containing copper-modified graphene are obtai...

Embodiment 2

[0039] A method for making a light conductive wear-resistant bar, the specific steps are as follows:

[0040] The first step, making graphene carbon fiber filaments

[0041]In a clean environment, single graphene with a microchip thickness ranging from 0.5nm to 6nm is selected, and a copper / silver alloy with a particle size of 2nm is deposited on the surface of the single graphene to obtain copper / silver alloy modified graphene. The copper / silver alloy modified graphene ensures that the mass content of copper is between 0.1% and 3%, and the mass content of silver is between 0.05% and 1.5%, and the content of the prepared copper / silver alloy is between 0.05% and 4% copper / silver alloy modified graphene is dissolved in the carbon fiber sizing agent, and after conventional spinning and continuous carbon fiber production line processing, a carbon fiber filament containing copper / silver alloy metal modified graphene is obtained, ready for use .

[0042] The second step is to prep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap