Model pile internal force rating device and method

A calibration device and model pile technology, applied in the field of model pile internal force measurement device, can solve problems such as increasing the test cost, and achieve the effects of easy disassembly, low center of gravity and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

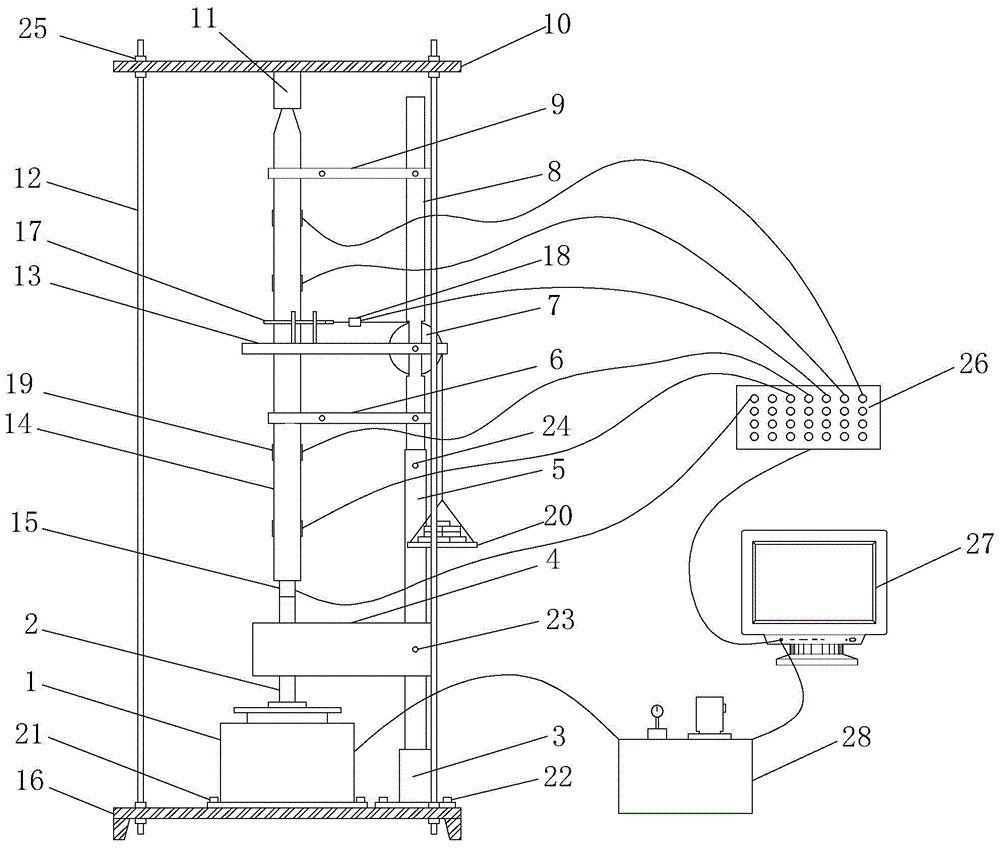

[0046] Such as figure 1 As shown, a device for calibrating the internal force of a model pile body of the present invention includes a small hydraulic jack 1, a force transmission chassis 2, a support rod fixing base 3, a guide block 4, a lower support rod 5, and a lower direction support 6 , pulley 7, upper support rod 8, upper direction support 9, pressure-bearing top plate 10, pile tip pad 11, force transmission pull rod 12, horizontal force direction support 13, model pile 14, pressure sensor 15, base 16, horizontal Force transmission frame 17, tension sensor 18, strain gauge 19, load plate 20, jack fixing bolt 21, base fixing bolt 22, bracket fixing bolt 23, support rod adjusting bolt 24, tie rod fixing bolt 25, strain acquisition instrument 26, computer 27. Hydraulic pump 28. The small hydraulic jack 1 is fixed on the center of the base 16 by the jack fixing bolt 21; the force transmission chassis 2 is overlapped directly above the small hydraulic jack 1, and the beari...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com