A scalable gear fatigue test bench and method for calculating the number of stress cycles

A fatigue test and scalability technology, applied in the field of gears, can solve the problems of fixed span or small adjustment range, not suitable for large gear fatigue test, not suitable for gear fatigue test, etc., to achieve a wide range of rotation speed, measurement and calculation Simple and convenient, fast test effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

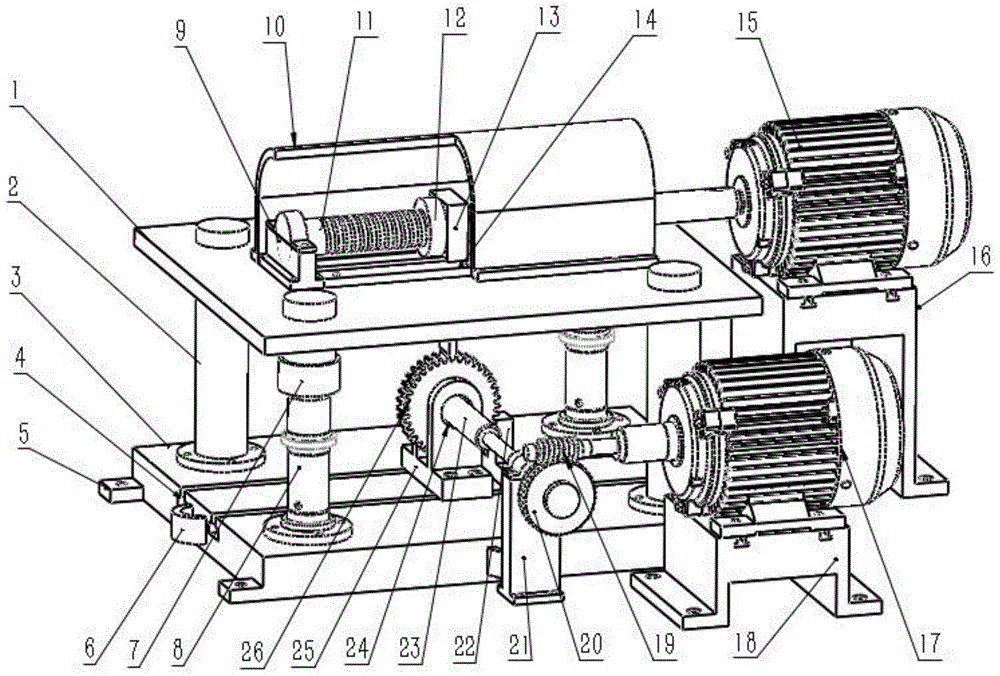

[0032] Such as figure 1 As shown, a scalable gear fatigue test bench includes: a loading part, a gear installation part and an upper top plate telescopic part;

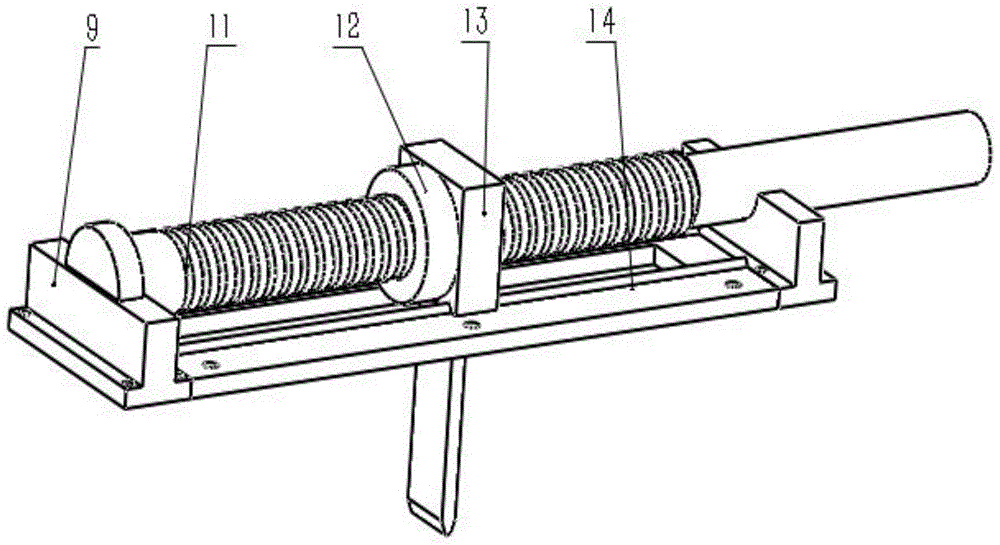

[0033] The loading part includes an upper top plate 1, a screw base 9, a dust cover 10, a screw 11, a nut 12, a V-shaped block test thimble 13, a guide rail 14, a loading motor 15 and a loading motor base 16;

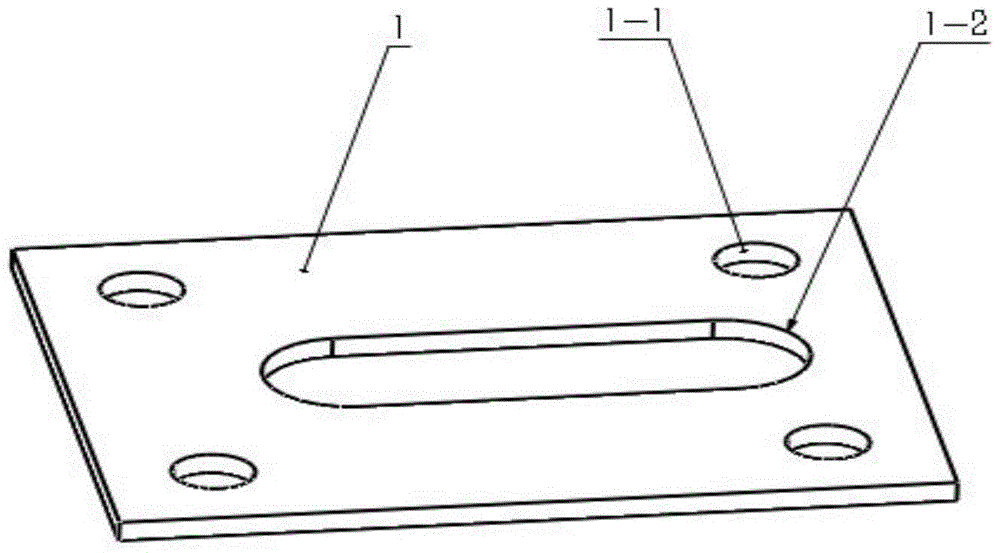

[0034] A guide rail 14 is provided on the upper top plate 1, and a lead screw base 9 is provided at both ends of the guide rail 14. In the lead screw base 9, a lead screw 11 is arranged above the guide rail 14, and is driven by a loading motor 15. The screw 11 is equipped with a nut 12 and a V-shaped block test thimble 13 on the nut 12; the material used for the V-shaped block test thimble 13 is hard alloy steel material, which has high hardness, wear resistance and impact resistance; the loading part The ball screw mechanism drives the screw 11 to rotate through the loading motor 15, the loading motor 15 is f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com