Method of overprinting color mark on gravure printing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The method for overprinting a color mark with a gravure printing machine of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] The invention discloses a method for overprinting a color mark on a gravure printing machine, the specific steps of which are as follows:

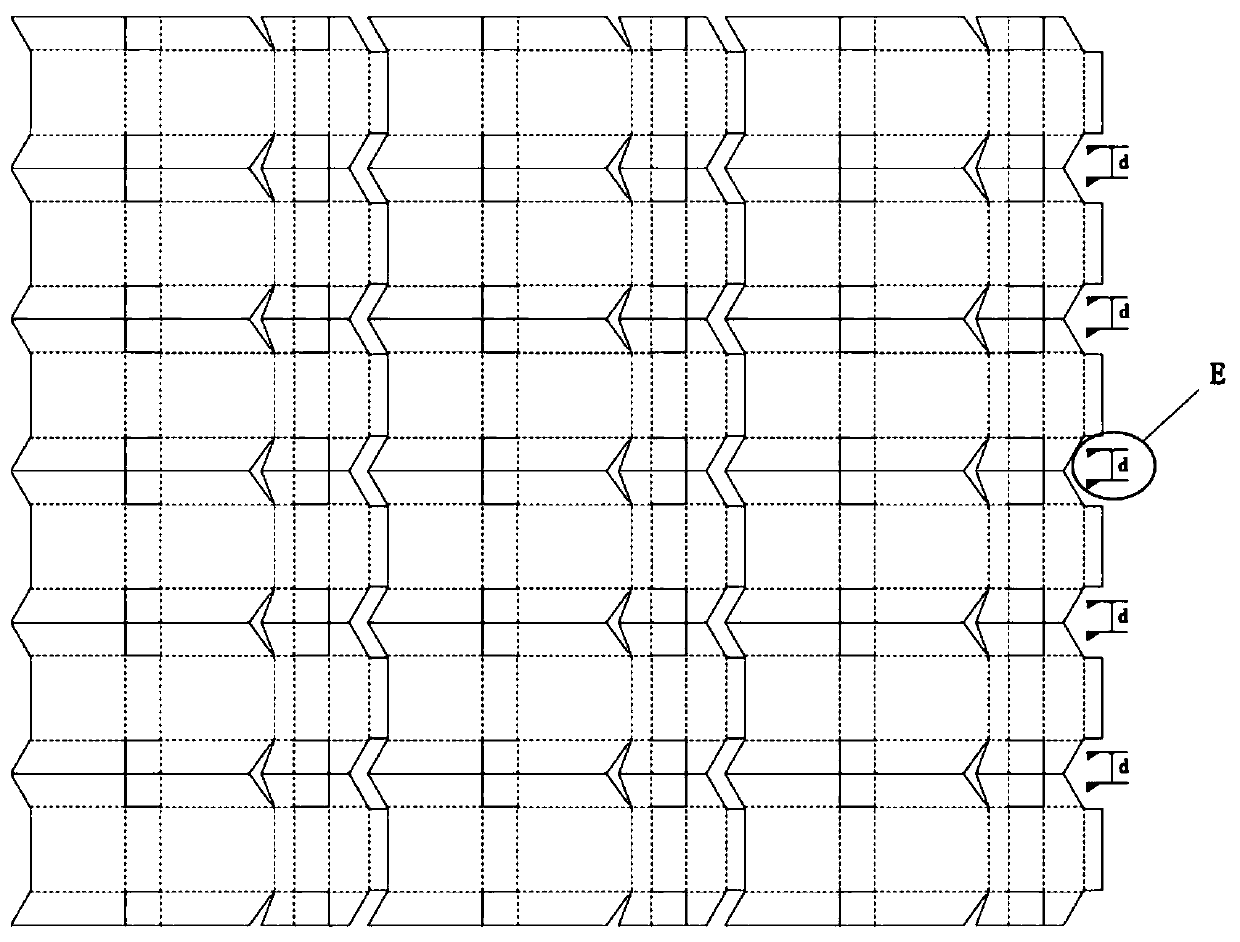

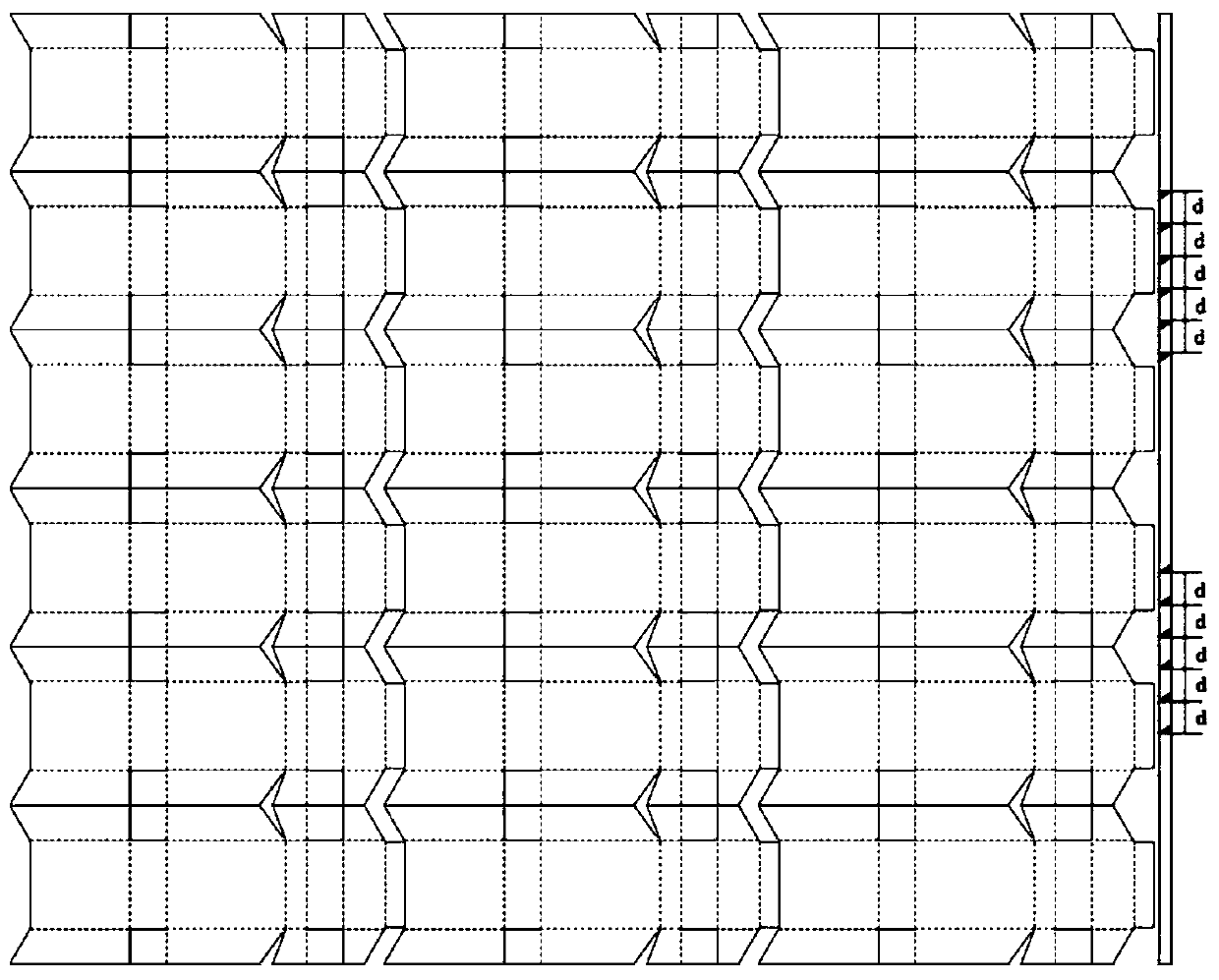

[0030] (1) The selected product, the product in this example is a small box of eighteen packs of cigarettes, and the number of printing colors is ten colors (specifically as figure 1 As shown), the imposition plate of this product has a blank space on the paper with the same number of printing colors as the printed color of the product;

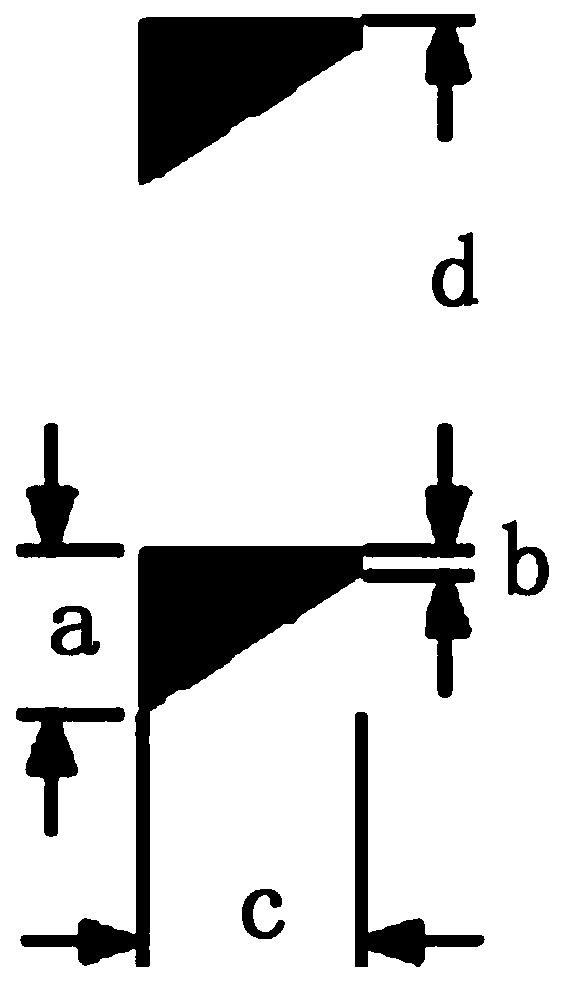

[0031] (2) Make the original manuscript in the computer, add all the above color codes to the blank space of the paper in the imposition core of the product, such as figure 1 Between the right edges of the two rows of cigarette packs in the box, five groups of small gray right-angled trapezoids in pairs are the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com