Method for determining stripping parameters for stripping cables

A de-insulation and cable technology, applied in the field of at least one de-insulation parameter of cable de-insulation, can solve the problems of unreliability, time-consuming and laborious, and achieve the effect of improving production safety again.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

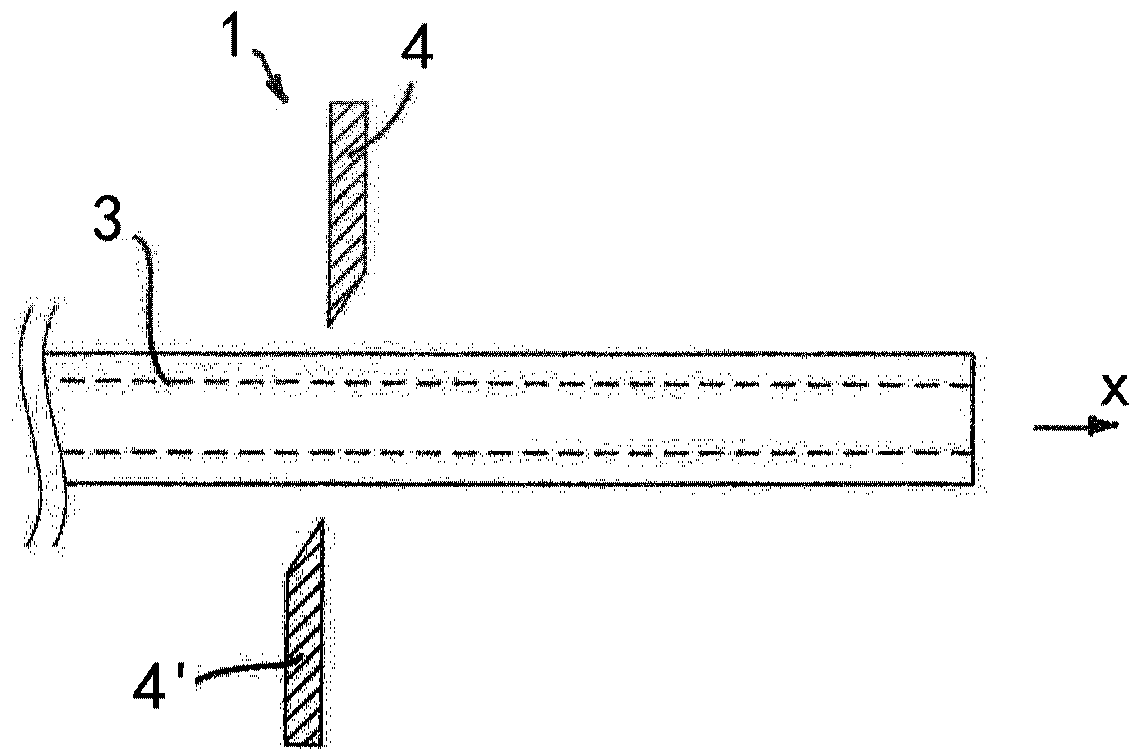

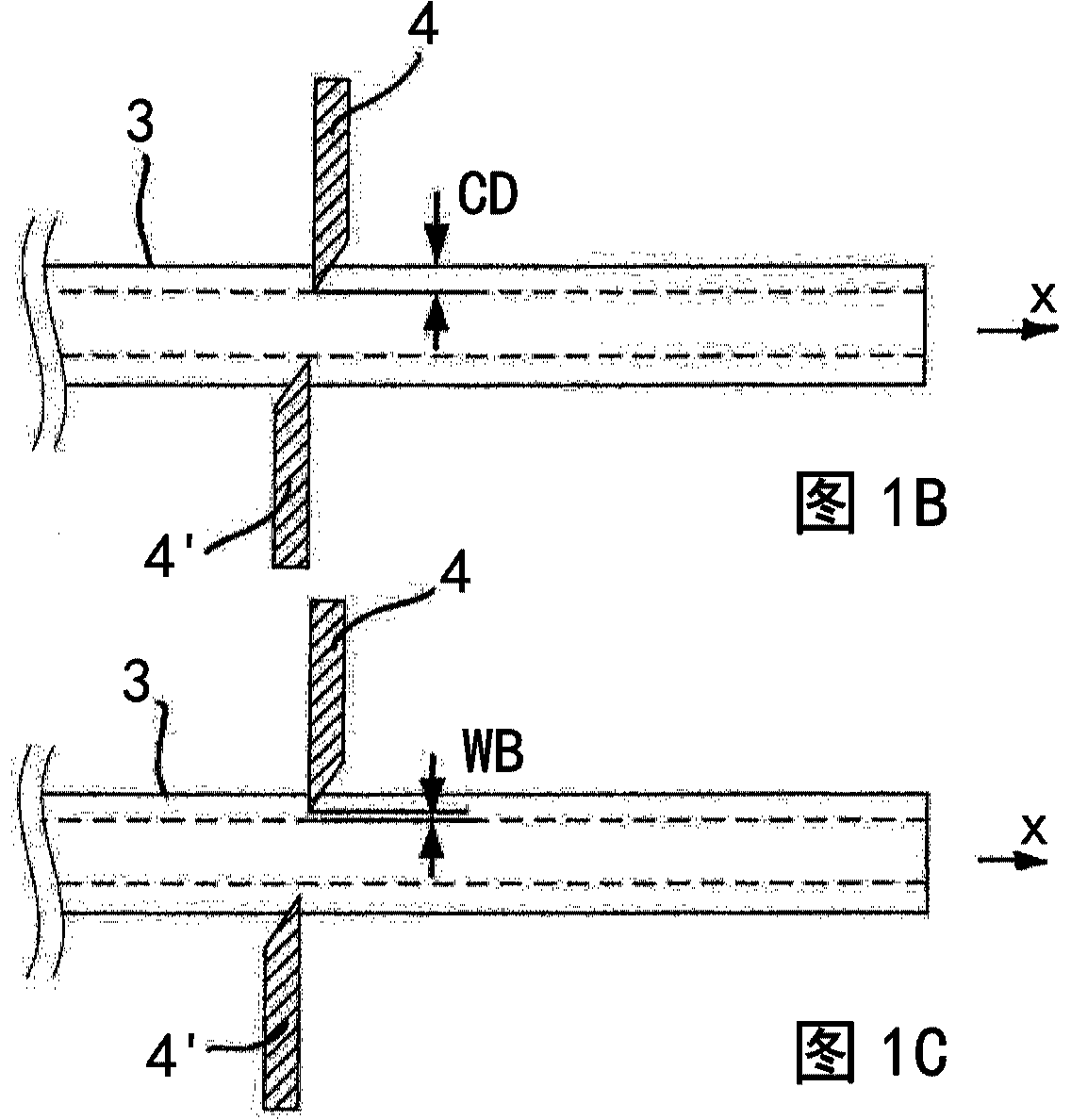

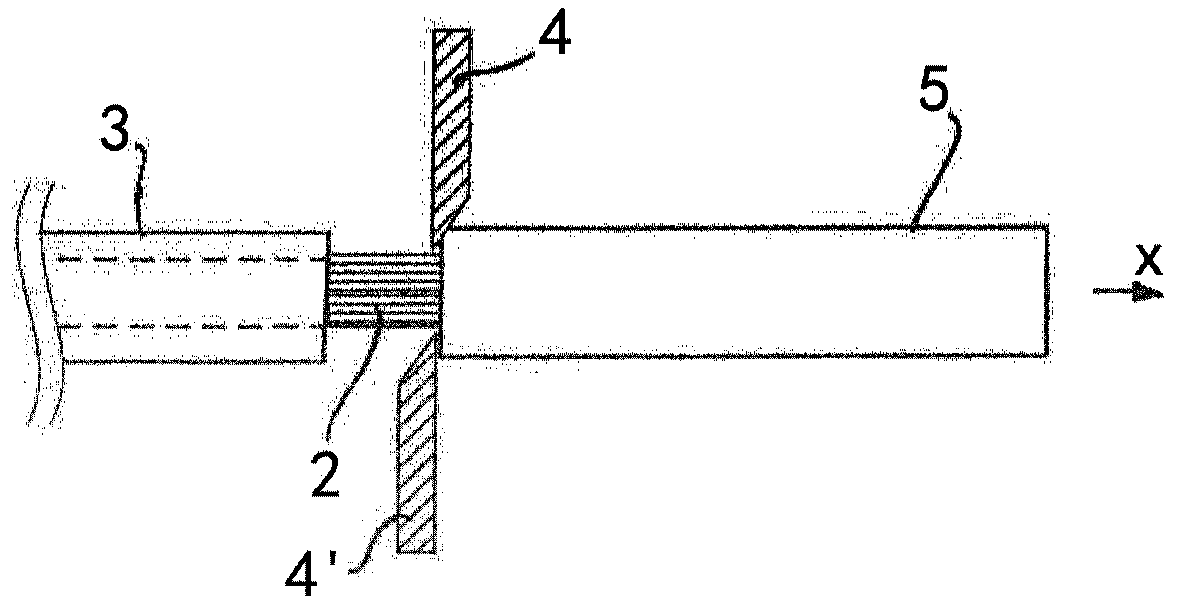

[0025] The device with a unit for stripping an electrical cable 3 , which is generally designated 1 in FIG. 1 , comprises a knife pair with two stripping knives 4 and 4' that can move toward each other. To cut the insulation, the knife can be moved radially towards the conductor 2 of the cable 3 . FIG. 1 shows the individual method steps known for stripping cables. When cutting in with a stripping knife, the depth of penetration of the knife should be set in such a way that the insulation 5 is cut in as deeply as possible without leaving one or more cores of the conductor 3 made of, for example, copper material or aluminum. nick. When pulling off, the penetration depth is usually slightly reduced, so that on the one hand the knife does not scratch the core. On the other hand, the stripping knife overlaps the insulation to the greatest extent possible: so that the insulating sheath can be reliably pulled off. Touching of the wires during the pull-out process can result in: d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com