Optical disk, recording and reproducing apparatus for the same, and method for managing address information

A technology of address information and reproducing device, which is applied in the direction of recording information storage, optical recording/reproducing, disc-shaped record carrier, etc., and can solve the problems of bad influence of header signal, high energy density of beam center, influence characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] CD

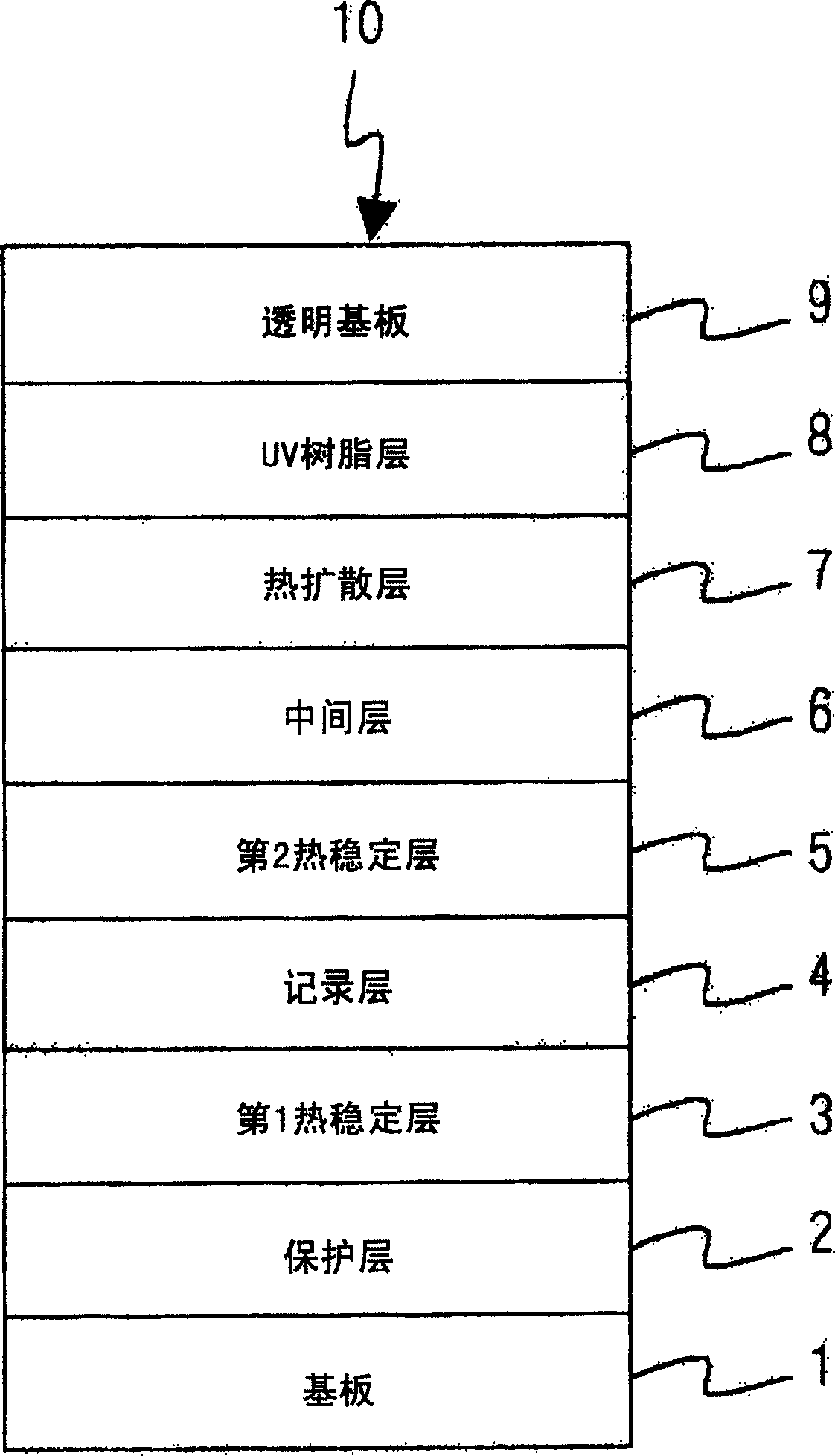

[0096] In Example 1, an optical disc of a phase change recording system was produced. FIG. 1 shows a schematic cross-sectional view of an optical disc produced in this example. As shown in FIG. 1 , the structure of the optical disc 10 produced in this example is that a protective layer 2 , a first thermally stable layer 3 , a recording layer 4 , a second thermally stable layer 5 , and an intermediate layer are sequentially laminated on a substrate 1 . 6. Thermal diffusion layer 7 , UV resin layer 8 and transparent substrate 9 . Next, a method for producing an optical disc of this example will be described.

[0097] First, a substrate 1 made of polycarbonate with a diameter of 120 mm and a thickness of 0.6 mm was produced by injection molding using a press molding machine. At this time, on the substrate 1, grooves (grooves) having a track pitch of 0.34 μm and a depth of 45 nm were formed in the recording area of the optical disc having a radius of 23.8 mm to 58...

Embodiment 2

[0156] In Example 2, various optical discs were produced in the same manner as in Example 1 except that the information recording and reproducing apparatus for measuring the bit error rate was changed, and quality evaluation of address signals and data signals was performed.

[0157] Information recording and reproducing device

[0158] FIG. 5 shows a schematic configuration diagram of an information recording and reproducing apparatus for recording and reproducing information on the optical disc produced in this example. The information recording and reproducing apparatus 200 used in this example is as shown in FIG. The / G servo circuit 13, the reproduction signal processing system 24, and the recording signal processing system 17 are constituted. As can be seen from FIG. 5, the structure of the information recording and reproducing apparatus 200 shown in FIG. 5 is the same as that of the information recording and reproducing apparatus 100 shown in FIG. Configuration of the...

Embodiment 3

[0165] In embodiment 3, except changing the recording format of address information and data information of the optical disc, all the other are produced various optical discs in the same manner as in embodiment 1, and use the information recording and reproducing device shown in Figure 5 to measure the bit error rate as in embodiment 2, and carry out Quality evaluation of address signals and data signals.

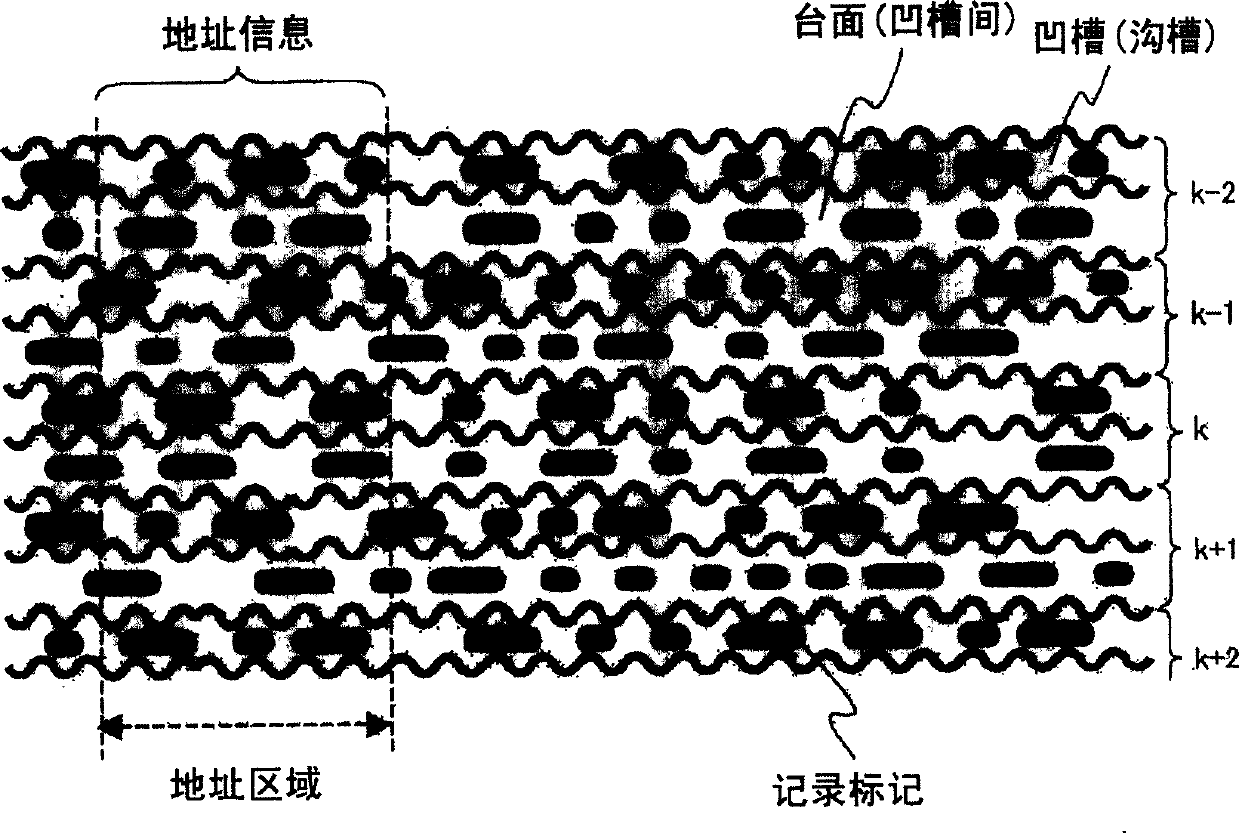

[0166] CD

[0167] FIG. 6 is a schematic diagram showing the recording format of address information and data information of the optical disc produced in this example. In the optical disc of FIG. 6 , data information (recording marks) are recorded on the land, and address information of the track is formed by radially wobbling the groove. In the optical disk of FIG. 6, a set of adjacent grooves and lands is regarded as one track, and the same track number is assigned to the grooves and lands. That is, the address information formed in the groove in the optical disc of FIG...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com