Two-way positioning small stress assembly structure and its assembly method

A technology of two-way positioning and assembly structure, applied to the rigid bracket of bearing components, manufacturing tools, mechanical equipment, etc., can solve the problems of poor reliability and stability, cracked shaft sleeve, limited application, etc., to improve reliability and assembly. Small stress, the effect of preventing relative sliding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

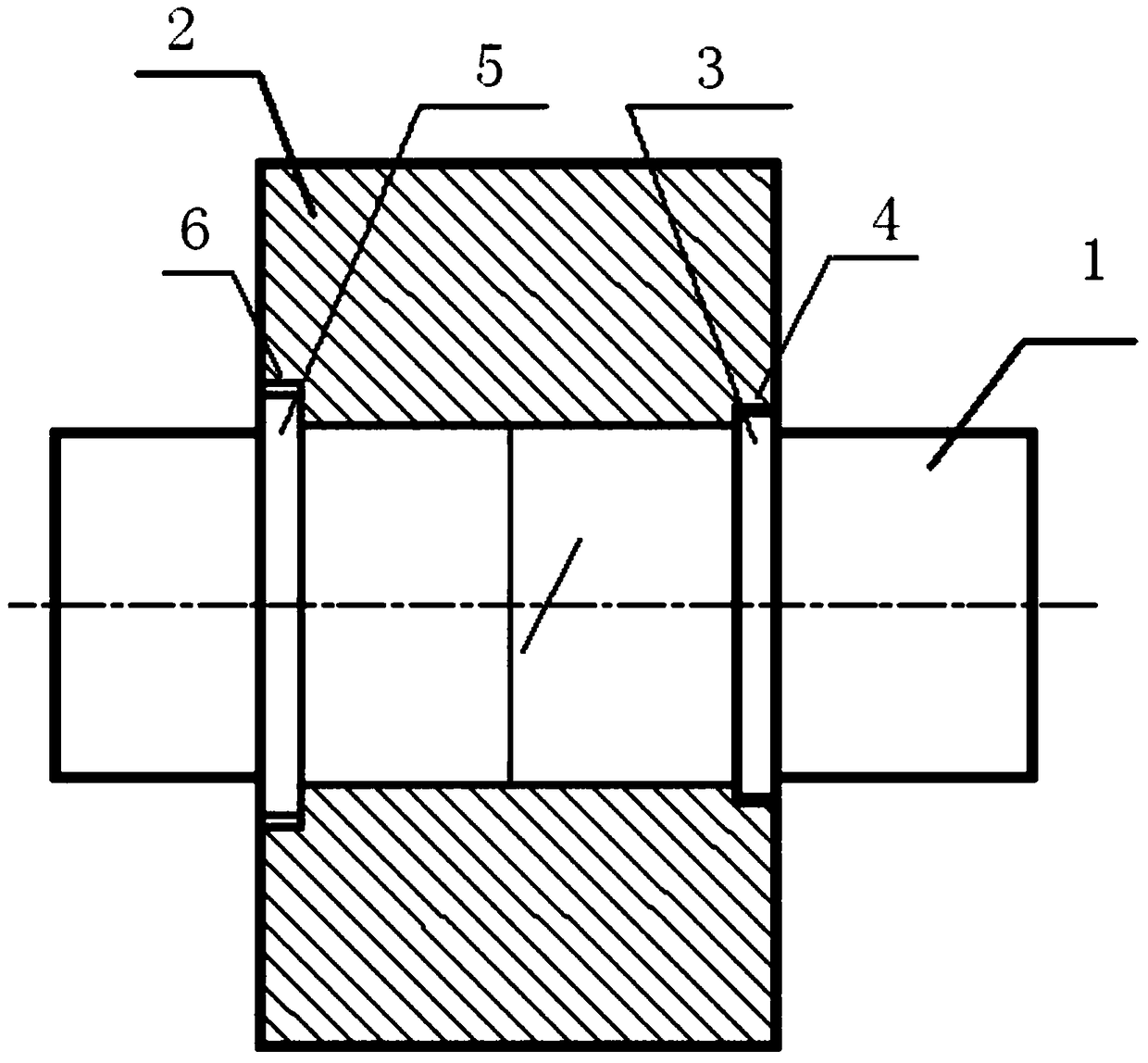

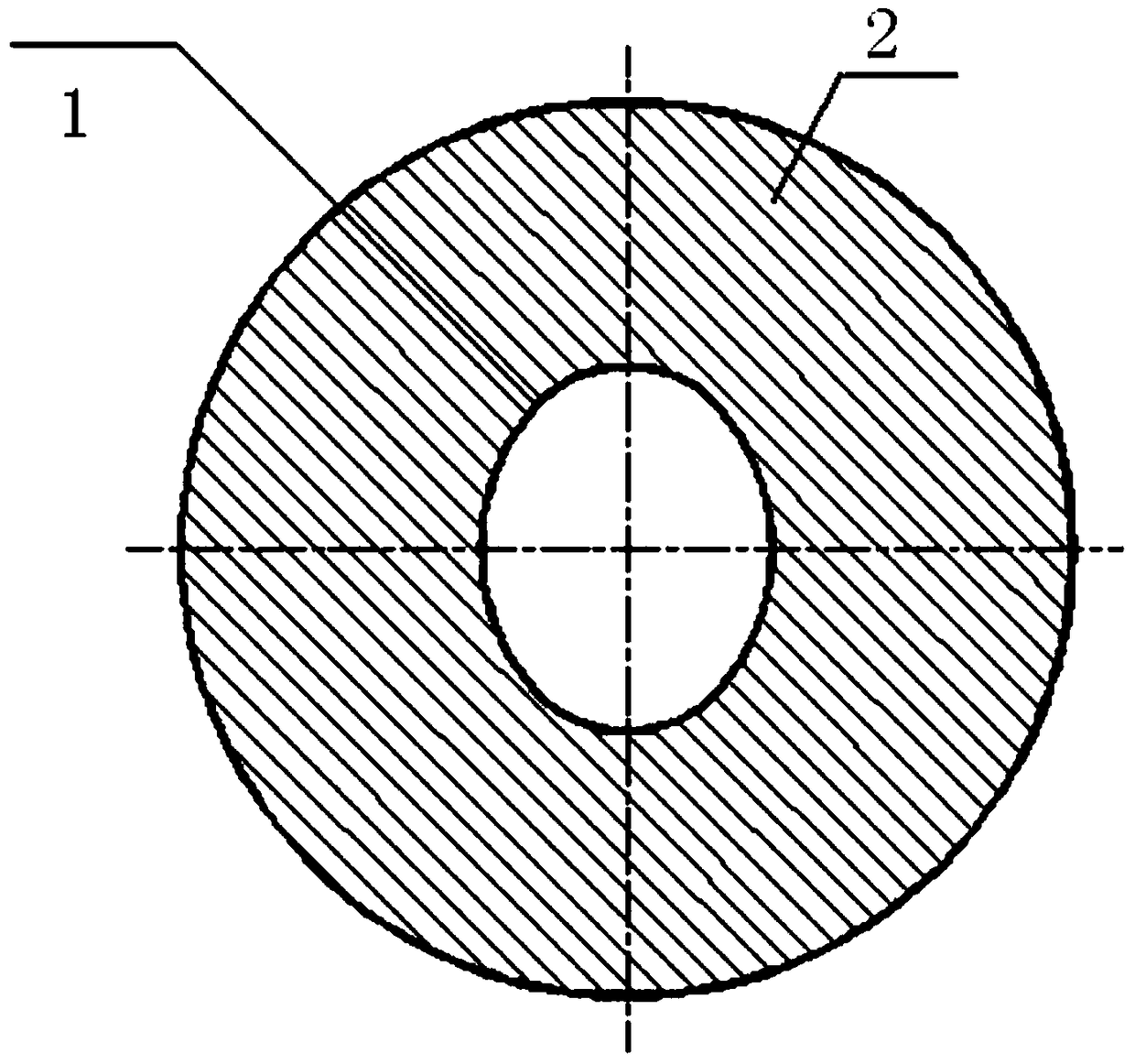

[0055] (1) Determine the fit curve form according to the transfer torque: preferably a standard elliptic curve. The major axis of the ellipse is 1003mm, and the minor axis is 1000mm;

[0056] (2) Determine and calculate the interference amount according to the assembly datum: the interference amount is 0.25mm, the section curve of the shaft is also a standard ellipse curve, the tolerance range: 0~+0.05, the section curve of the shaft sleeve is the same as the standard ellipse in step 1 Curve, tolerance range: -0.05~0;

[0057](3) Determine the diameter and length of the stop step on the shaft. The diameter of the stop step is 1.2mm offset from the major axis of the elliptic curve, that is, 1004.2mm, and the length of the stop step is 100mm;

[0058] (4) Determine the diameter and length of the anti-retraction groove in the inner hole of the shaft sleeve that matches the anti-retreat step. Among them, the diameter of the stop groove is 1004.5mm and the length is 104mm;

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com