Positive displacement pump assembly with movable end plate for rotor face clearance control

A positive displacement pump and end plate technology, applied in the components of the pumping device for elastic fluid, rotary piston type/swing piston type pump components, pump components, etc., can solve the inefficiency of positive displacement air pump , air leaks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

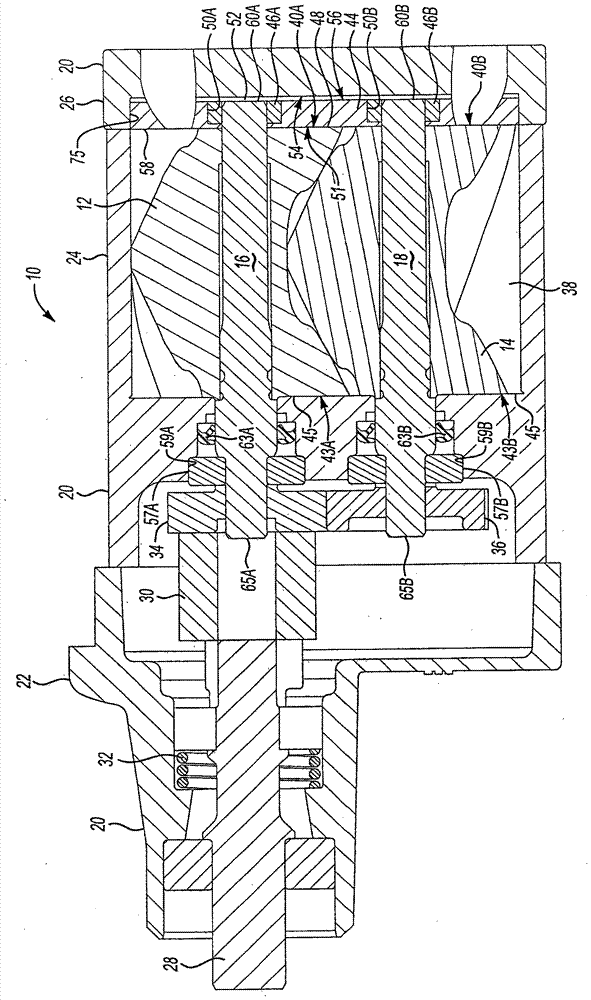

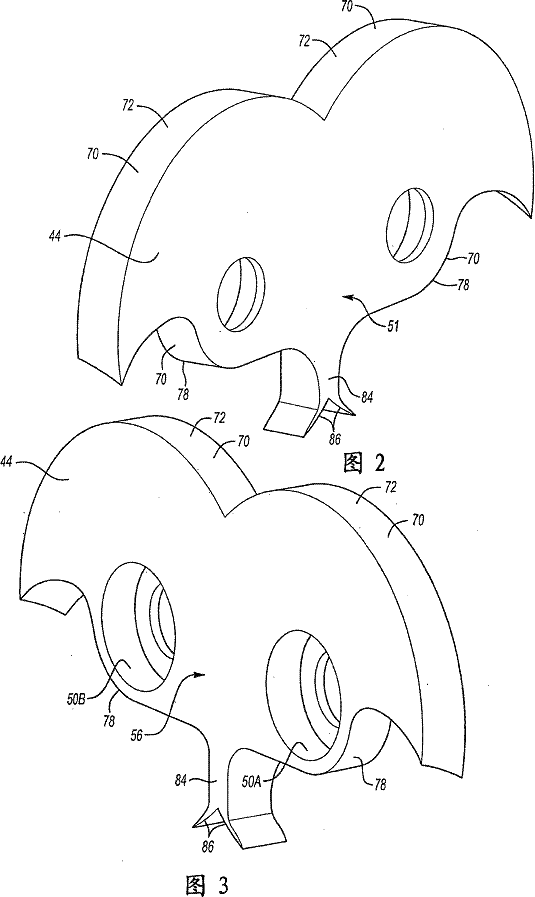

[0014] Referring to the drawings, wherein like reference numerals indicate like components throughout the views, figure 1 A positive displacement pump assembly 10 is shown. In this embodiment, the positive displacement pump assembly 10 is a supercharger assembly for an engine, but the positive displacement pump assembly 10 may be used for pumping other fluids and in other applications. The positive displacement pump assembly 10 has a first rotor 12 meshing with a second rotor 14 . Each rotor 12, 14 has a plurality of lobes. The first rotor 12 is mounted on and rotates with the first rotor shaft 16 . The second rotor 14 is mounted on and rotates with a second rotor shaft 18 , which is generally parallel to the first rotor shaft 16 .

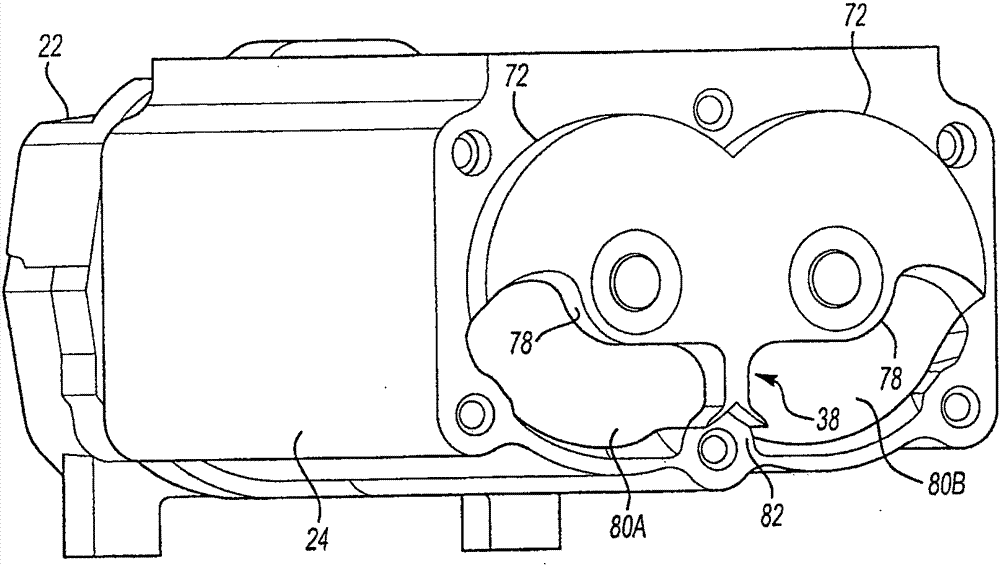

[0015] The rotors 12 , 14 and rotor shafts 16 , 18 are housed within a multi-component positive displacement pump housing 20 . The housing 20 includes a front cover 22 , a middle portion 24 , which may be referred to as a rotor housing portion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com