Wind energy facility with drive train

A technology for wind power generation equipment and drive trains, which is applied to wind power generation, wind turbines, mechanical equipment, etc., and can solve problems such as high consumption and unfavorable connections.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

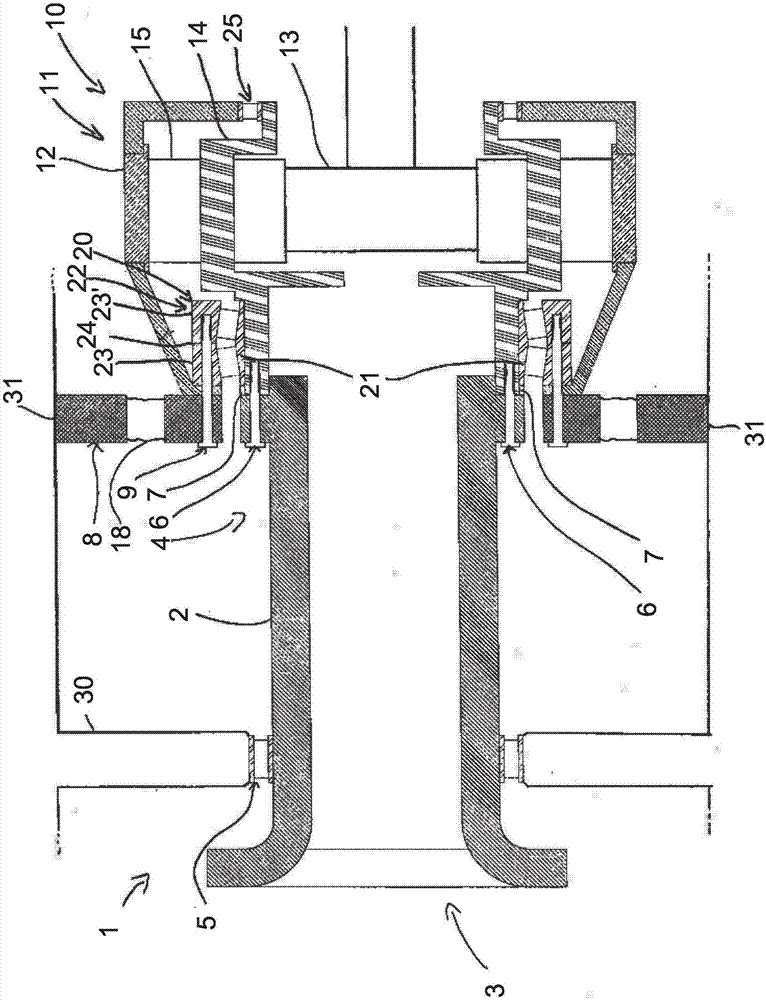

[0028] figure 1 A drive train 1 of a wind power plant according to the invention with components relevant to the invention is schematically shown in .

[0029] The drive train 1 comprises a rotor shaft 2 to which a rotor of the wind power plant can be fastened at an end 3 . A planet gear 10 is arranged at the other end 4 of the rotor shaft. Only the first gear stage 11 of the gear transmission 10 is shown.

[0030] The first gear stage 11 comprises an internally toothed hollow gear 12, an externally toothed sun gear 13 and a planet carrier 14 with orbiting gears 15 arranged thereon as gear parts, which are engaged to the In the toothing of the hollow wheel 12 and in the toothing of the sun wheel 13 . The ring gear 12 is fixedly connected to the gear housing 16 , while the sun gear 13 is mounted rotatably relative to the gear housing 16 via rolling bearings (not shown for the sake of clarity). The support of the planetary carrier 14 in the gear housing 16 via the double-row...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com