Loading control device and loading control method

A control method and loading technology, which is applied in the direction of program control, program control, and electrical program control in the sequence/logic controller, can solve the problems of low loading speed, complicated operation, and complex hydraulic cylinder structure, and achieve The effect of reliable loading force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below through specific embodiments in conjunction with the accompanying drawings.

[0034] Considering that the traditional weapon loading system is controlled by a hydraulic cylinder, resulting in complex loading technical structure and complex system design, the present invention provides a loading control device and a loading control method.

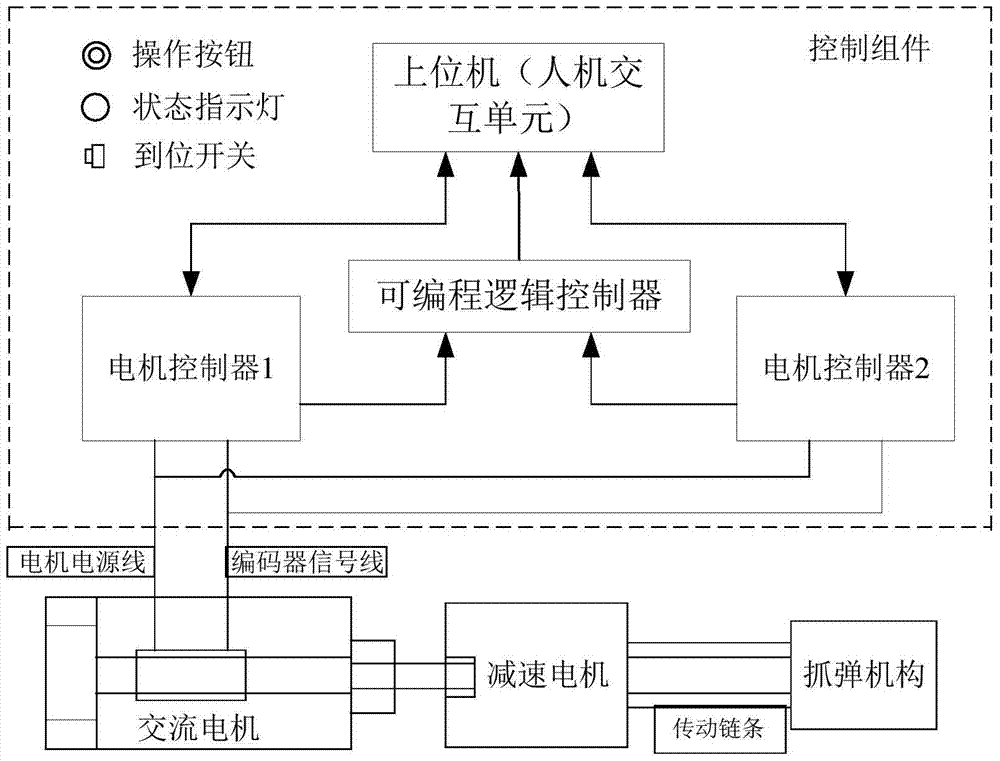

[0035] The loading control device includes: a motor unit, more than one sensor and a control assembly; wherein, the motor unit is connected to the loading mechanism through a transmission assembly, the control unit is connected to the motor unit through a signal line, and a sensor is arranged on the signal line.

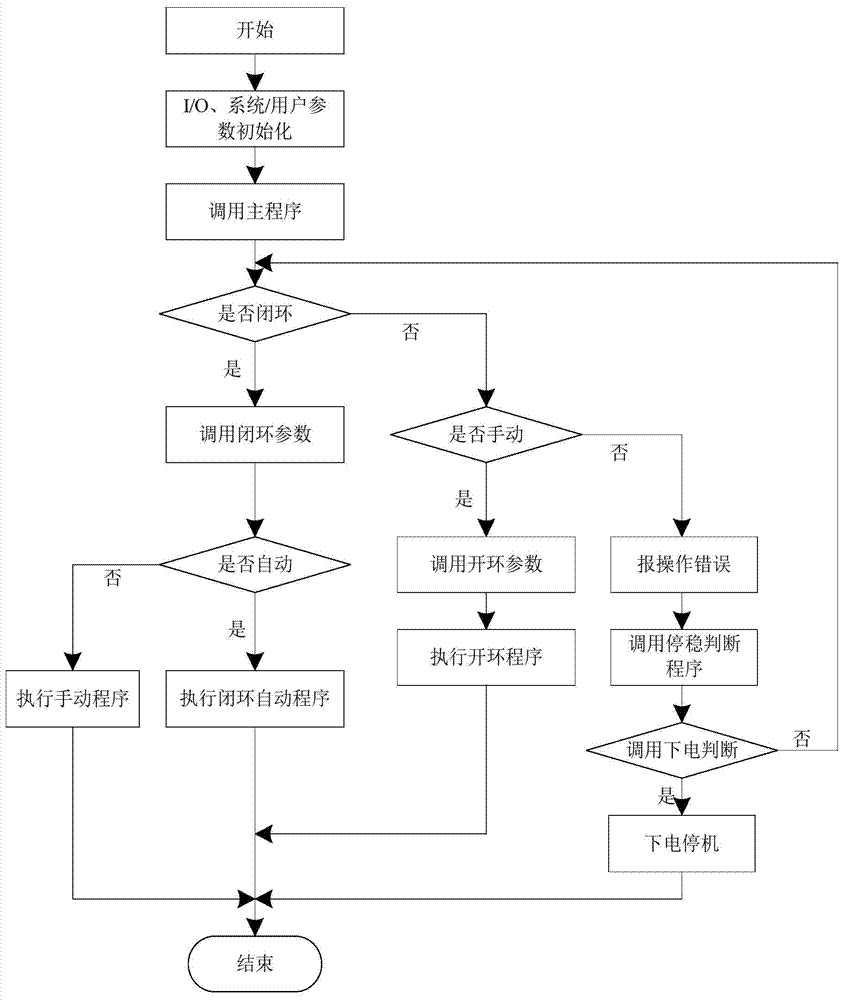

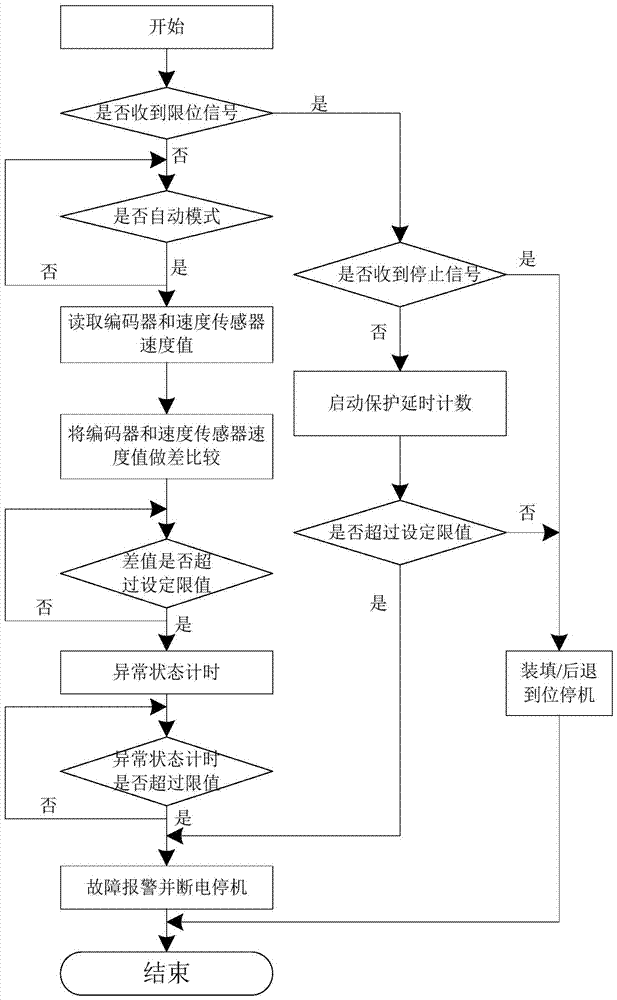

[0036] The control method for executing the above-mentioned loading control device includes:

[0037] Step 1, power on, perform initialization processing, and the motor controller of the control component receives the data of the sensor;

[0038] Step 2, the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com