Process For Production Of Knitted Articles

A product and knitting machine technology, applied in warp knitting, textiles, papermaking, knitting, etc., can solve problems such as low resolution, dissatisfaction, and half resolution of knitting design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

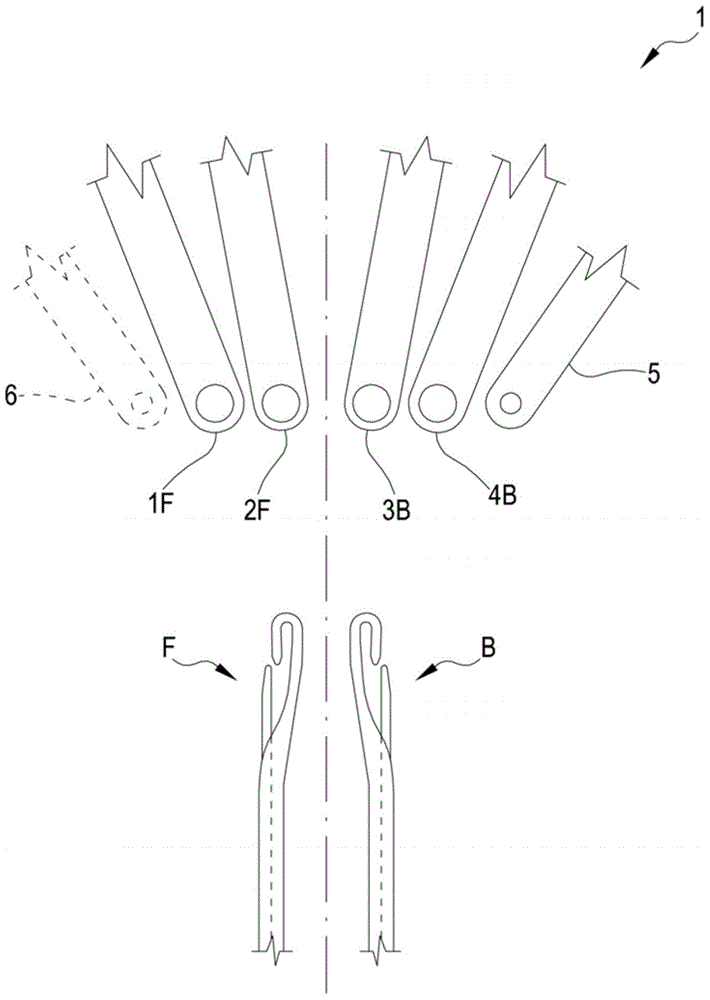

[0203] Referring to the drawings, the reference numeral 1 as a whole designates a linear knitting machine for implementing the method according to the present invention. In general, the same reference signs may be used for the same or similar elements in its modified embodiments.

[0204] figure 1 A part of a linear knitting machine for warp knitting is schematically shown, in particular a needle bed and a thread guide rod are schematically illustrated.

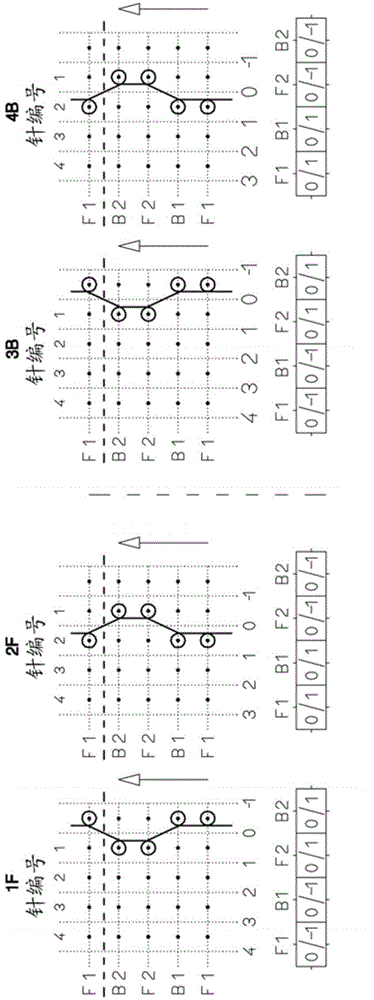

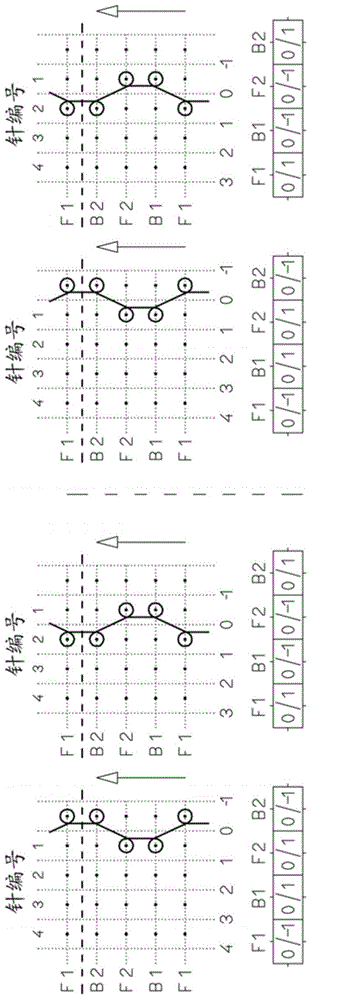

[0205] Some parts of the braiding machine, such as the frame, control unit, rod activation device, etc., are not shown in detail in the figure because they are known per se and are of conventional type: the schematic diagram of the braiding machine focuses on Understand the part of the knitting method of the present invention, especially the content that explains the knitting diagram of the following figures ( Figure 2 to Figure 26 , Figure 34 to Figure 40 ).

[0206] From the point of view of knitting technology, the operation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com