An adjustable self-stabilizing flow speed reducer for pipelines

An adjustable and self-stabilizing technology, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of pipeline occupation, rising product cost, influence, etc., and achieve the effect of achieving a stable flow rate range and realizing flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

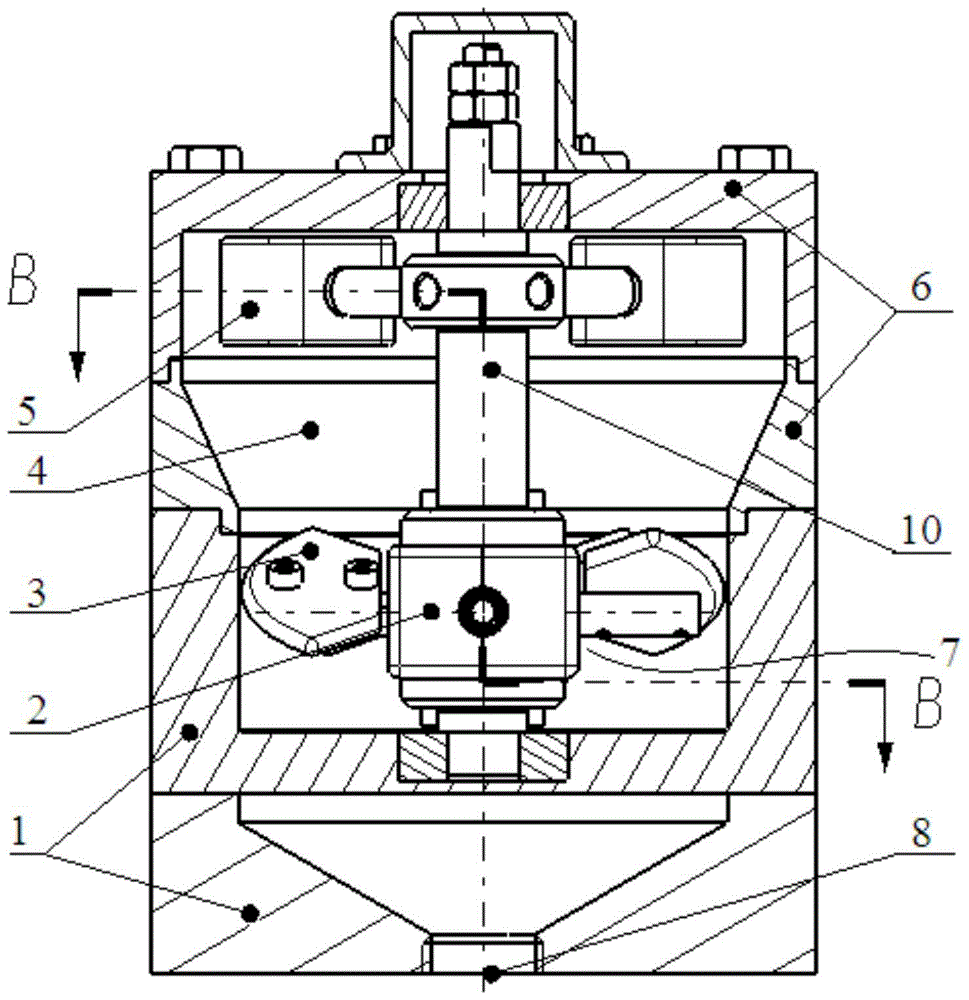

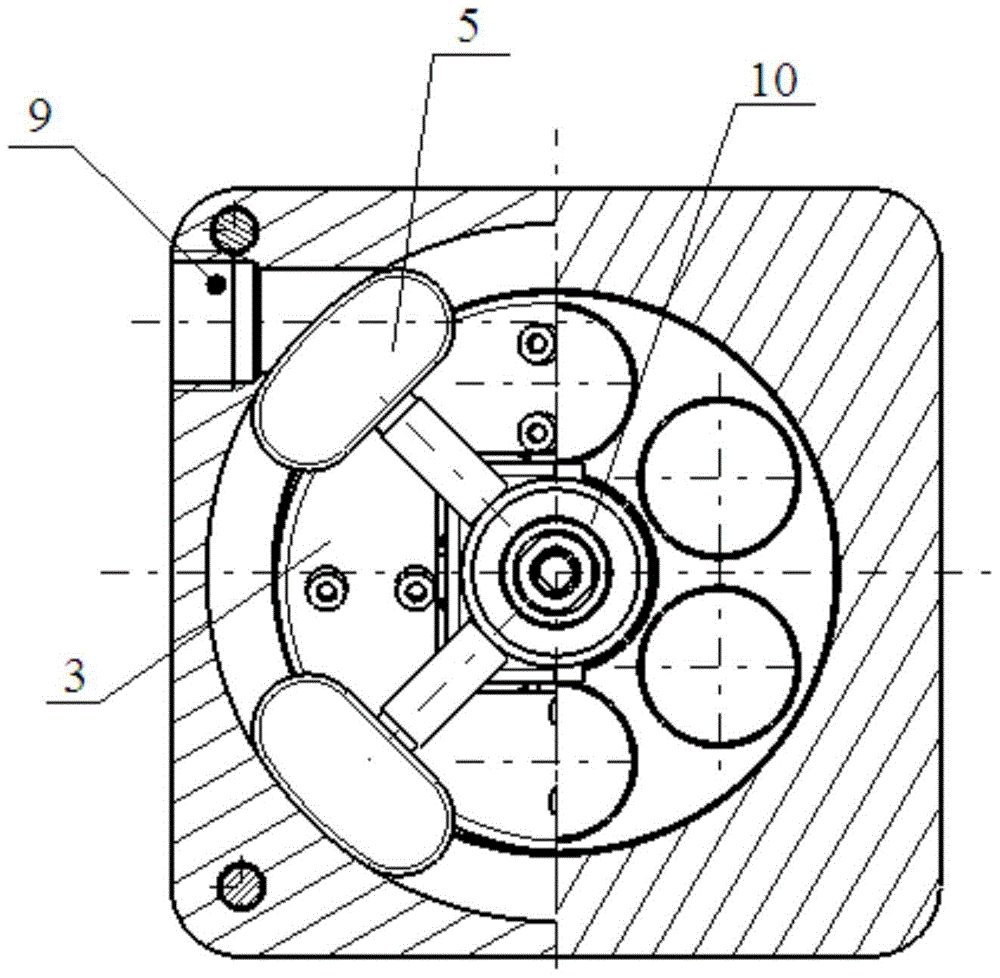

[0021] An adjustable and self-stabilizing flow rate reducer for pipelines, such as Figure 1 ~ Figure 2 As shown, the input mechanism 6 and the output mechanism 1 are included. After the input mechanism 6 is connected with the output mechanism 1, a cavity 4 is formed inside. The input mechanism 6 is provided with an inlet 9 and the output mechanism 1 is provided with an outlet 8, and the inlet The port 9 and the outflow port 8 are respectively connected to the pipeline, and a deceleration mechanism 7 is provided in the cavity 4.

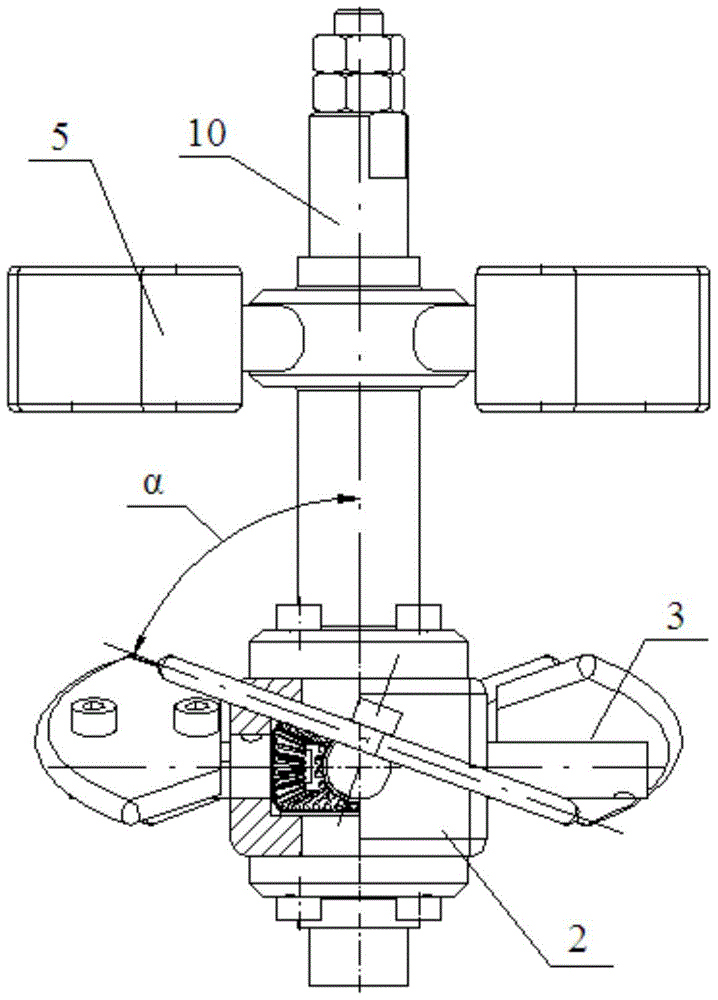

[0022] Such as image 3 As shown, the speed reduction mechanism 7 includes a main shaft 10, a plurality of blocking blocks 5 arranged on the upper end of the main shaft 10, a runner 2 arranged on the lower end of the main shaft 10, and a blade 3 arranged on the runner 2, and the upper end of the main shaft 10 passes The bearing is connected to the input mechanism 6, and the lower end is connected to the output mechanism 1 through the bearing. The runne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com