Friction stir welding fixture and temperature field feedback control method

A friction stir welding and feedback control technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of large thermal deformation and vibration of welded parts, and achieve the effect of negative feedback adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

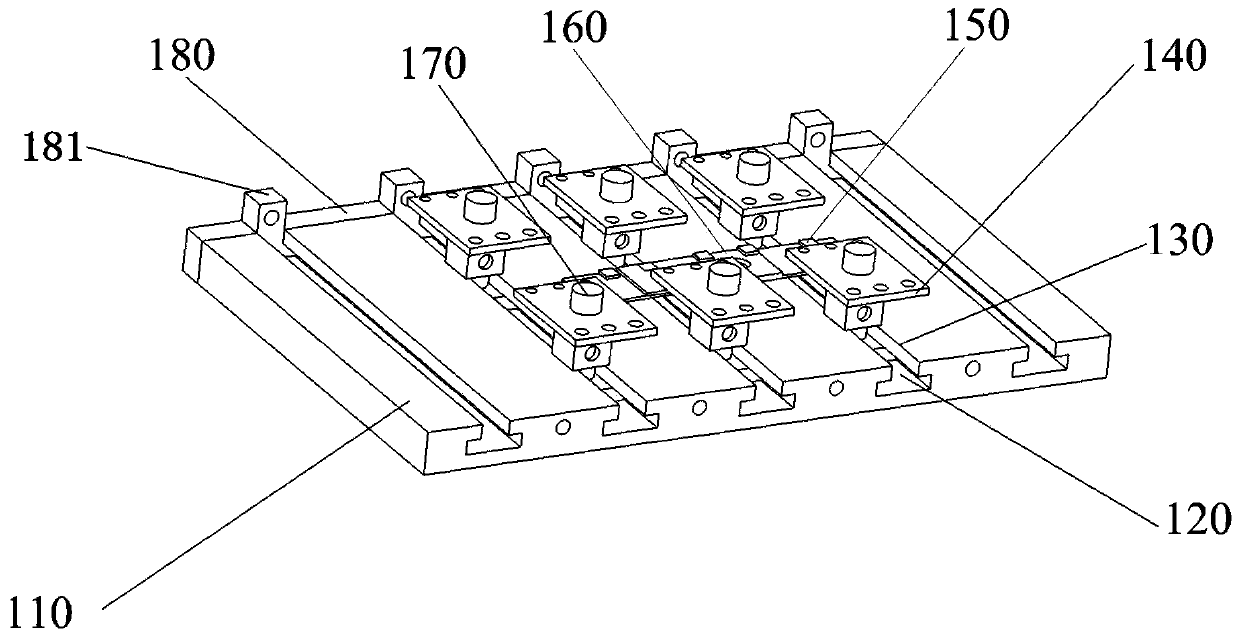

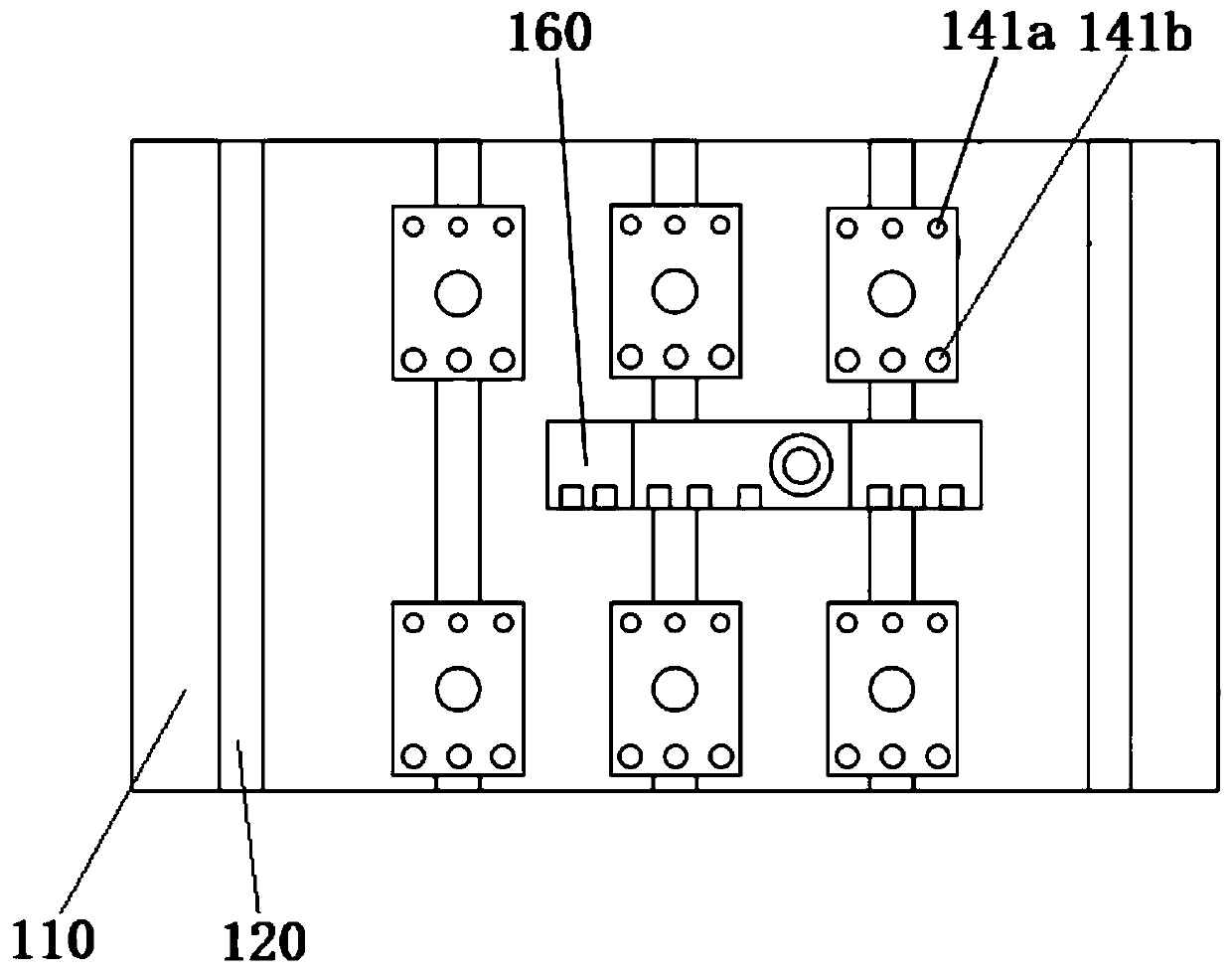

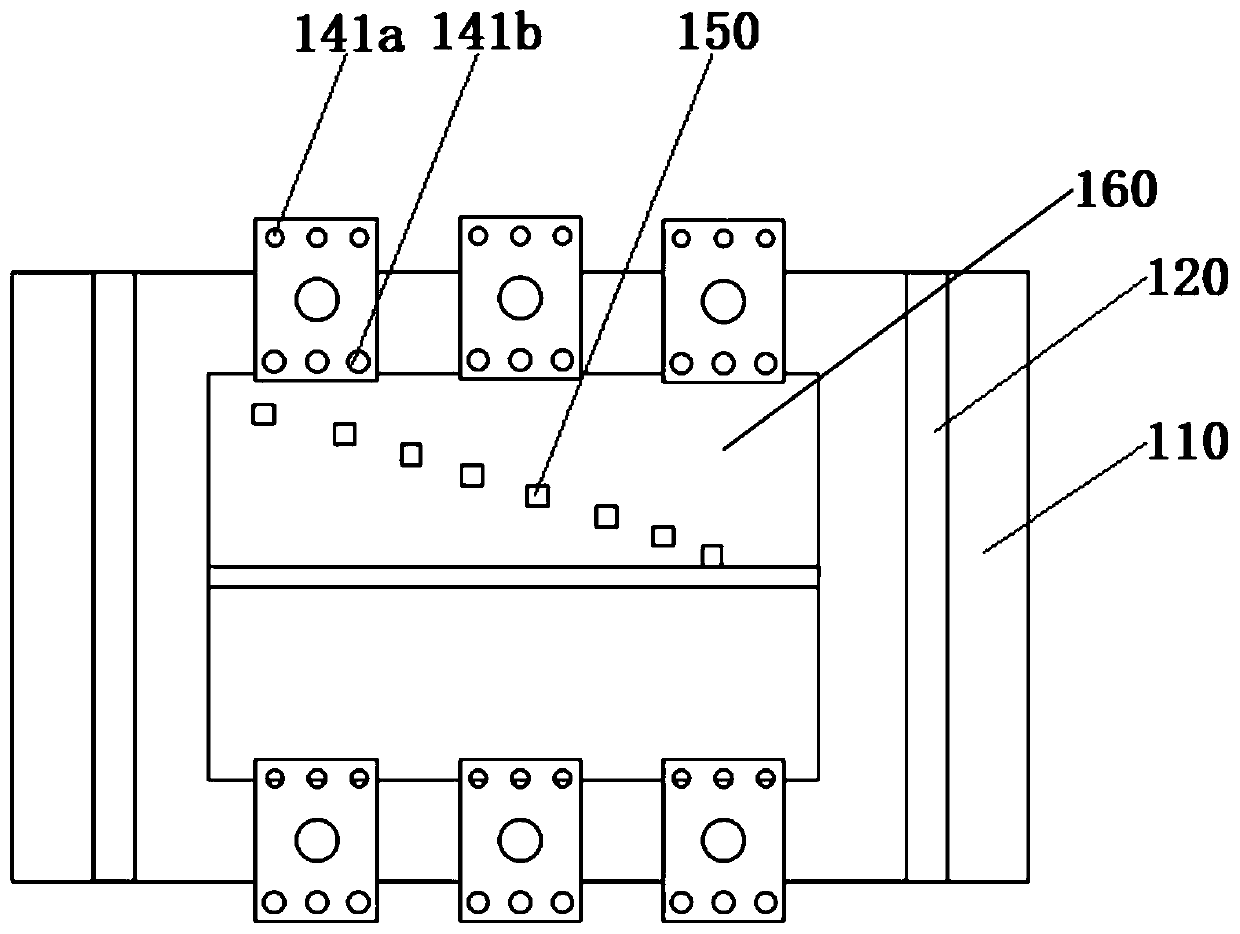

[0045] Such as Figure 1-6 As shown, the present invention provides a friction stir welding fixture, including: a base 110, a chute 120, a sleeve 130, a fixed block 140, a thermocouple 150, a unit to be welded 160, a slider 170, a side baffle 180 and a side fixing Block 181.

[0046] Such as Figure 1-3 As shown, the base 110 is placed horizontally on the ground. On the base 110, a plurality of chute 120 is provided. On the chute 120, a slider 170 is matched. The slider 170 has an external thread, and the sleeve 130 has an internal thread. , the sleeve 130 is matched and sleeved at the external thread. The fixed block 140 is provided with a circular hole, the fixed block 140 is arranged on the top of the sleeve 130, and is placed on the slide block 170, and the fixed block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com