A deformation-driven solid-phase extrusion device and a method for preparing alloy rods in one step using the device

An extrusion device and deformation technology, applied in the field of powder metallurgy, can solve the problems of insufficient refinement and coarsening of the structure of alloy materials, insufficient compactness, time-consuming and energy-consuming, etc., and achieve the goal of avoiding grain growth, low cost and high efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

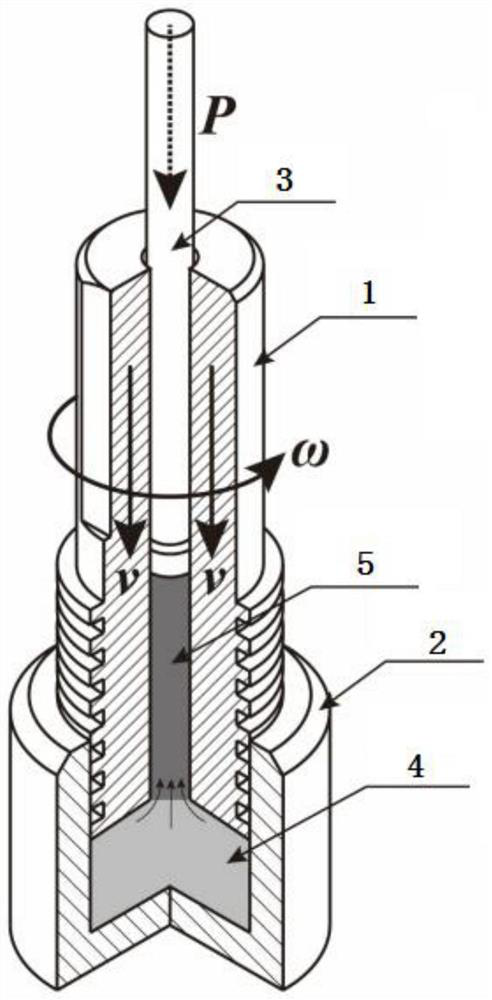

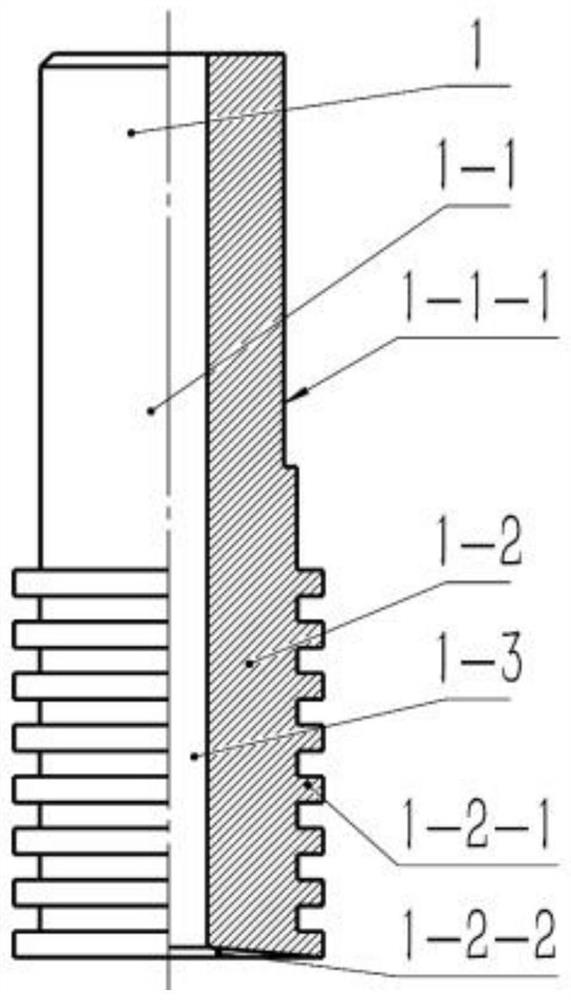

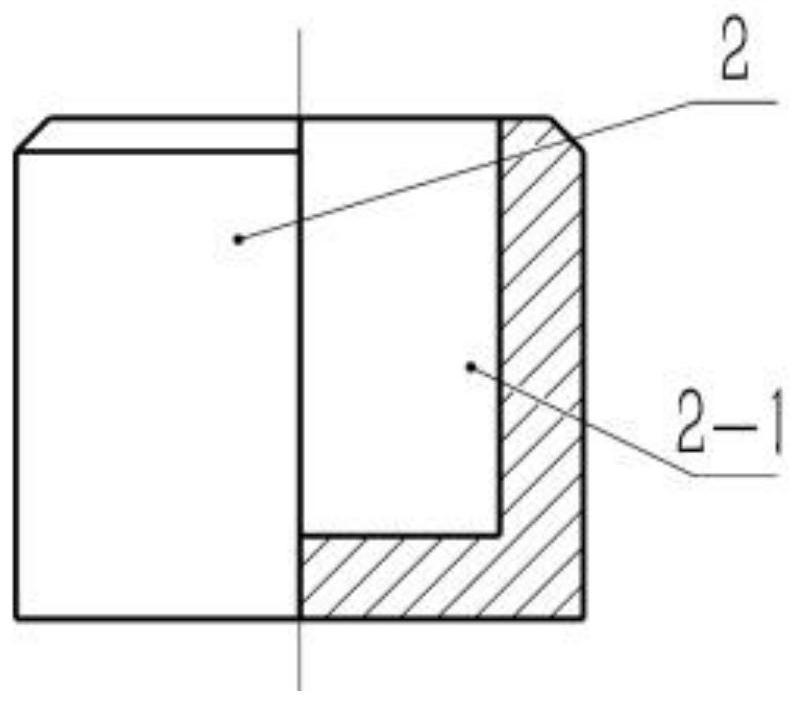

[0036] Embodiment 1: A deformation-driven solid-phase extrusion device in this embodiment includes a stirring head 1, an extrusion container 2 and a push rod 3. The stirring head 1 is composed of an upper mounting body 1-1 and a lower working body 1-2 An integrated structure with a hollow channel 1-3 is formed, the outer surface of the lower working body 1-2 is provided with a drag reducing groove 1-2-1, and the lower working body 1-2 is placed in the groove 2-1 of the extrusion container 2 , the ejector rod 3 is placed in the hollow channel 1-3 of the stirring head 1, the upper mounting body 1-1 and the lower working body 1-2 are cylinders, and the mounting surface is processed on the outer surface of the upper mounting body 1-1 1-1-1, the friction working surface 1-2-2 at the bottom of the lower working body 1-2 is a concave torus, and one end of the ejector rod 3 is an enlarged end 3-1;

[0037] The diameter of the upper mounting body 1-1 is 19.9mm;

[0038] The diameter o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com