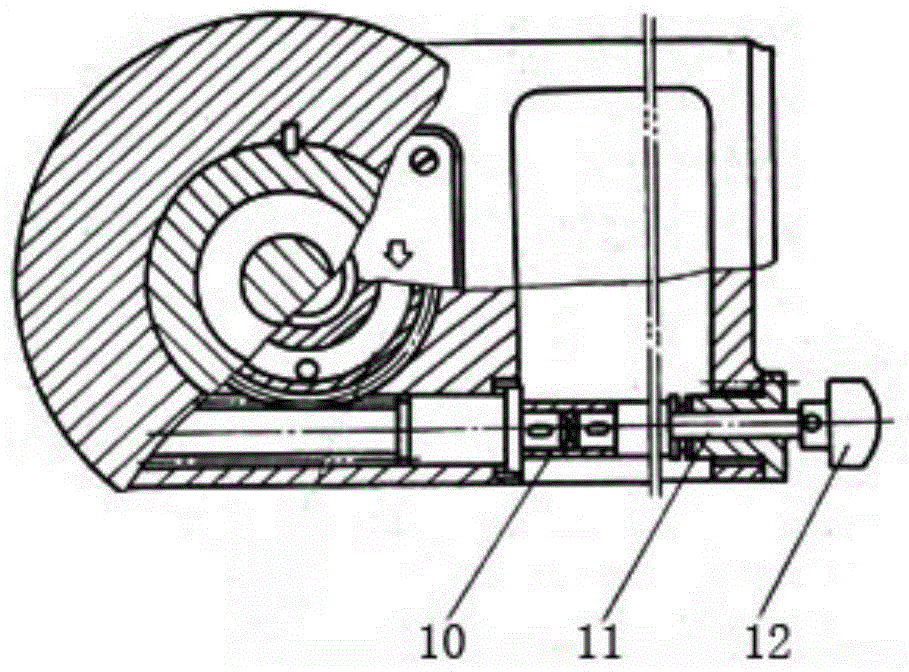

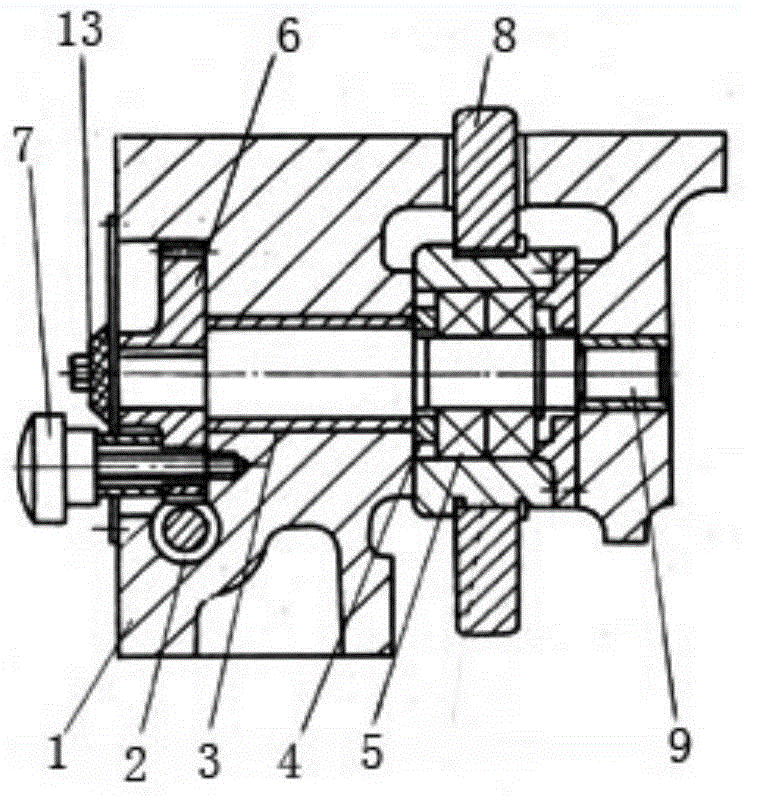

Pressure adjusting mechanism of downwards-pressing wheel

A technology for adjusting mechanisms and pressure rollers, applied to presses, manufacturing tools, etc., can solve problems such as low machining accuracy, rising production costs, and easy shaking of pressure rollers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0008] A pressure adjustment mechanism for the lower pressure wheel, comprising an eccentric shaft 9, the middle part of the eccentric shaft 9 is connected to the lower pressure wheel 8 through a bearing 5, and a worm wheel 6 is connected to the end of the eccentric shaft 9, and the worm wheel 6 Connected with a worm shaft 2, through the transmission of the worm shaft 2, the worm wheel 6 can be driven to rotate, so that the eccentric shaft 9 can rotate smoothly, thereby driving the lower pressure wheel 8 to rotate. In this embodiment , because the eccentric shaft 9 can drive the lower pressing wheel 8 to be adjusted up and down in the process of circular motion. As we all know, there is a forming mold on the tablet press, and through the change of the upper and lower positions of the lower pressing wheel 8, Different pressures can be given to the forming mold to meet the processing requirements of products with different thicknesses. In order to play a protective role, in this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com