Gasbag-type multifunctional wood board splicing machine

An airbag-type, multi-functional technology, which is used in the joining of wooden veneers, wood processing appliances, manufacturing tools, etc. Adapt to problems such as thickness changes and puzzles, so as to reduce certification and export inspection time, improve enterprise economic benefits, and reduce downtime and glue removal time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

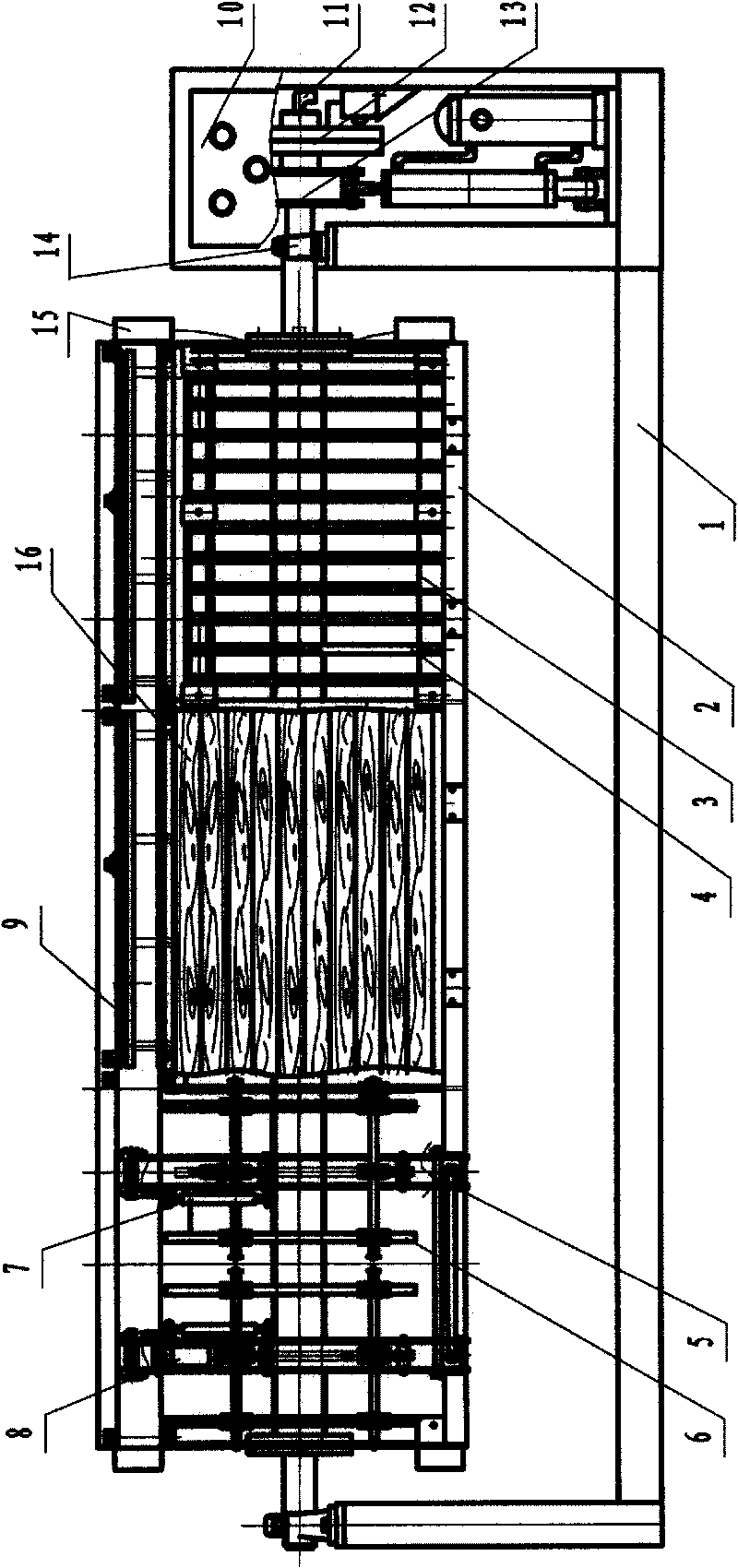

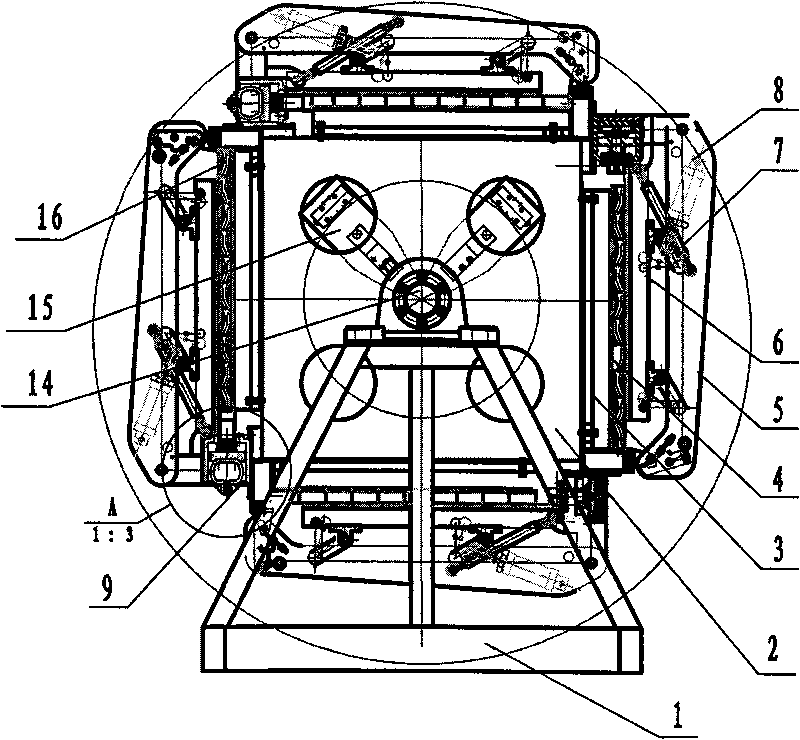

[0020] Embodiment 1, taking the four-sided workbench model as an example, see figure 1 , 2 , 4, 5, processed into a frame 1, the four-sided rotary workbench 2 is assembled into four completely identical surfaces forming an angle of 90 degrees each other, and the upper part of each workbench is processed with an aluminum alloy profile vertical rib plate 3, and Inlaid and laid polytetrafluoroethylene non-stick adhesive strips on the vertical ribs to form the bottom plane 4 of the workbench, and ensure that its flatness meets the geometric accuracy standard of the machine; install the pressure frame door 5 on the support of the rotary workbench 2 on each side, In order to open and lift the door and save effort, a door-lifting auxiliary cylinder or gas spring 7 is installed on the pressure frame door 5. At the same time, a side pressure clamping cylinder 8 is installed on the pressure frame door 5, and a four-link clamping mechanism 6 is connected to the piston rod. The side pres...

Embodiment 2

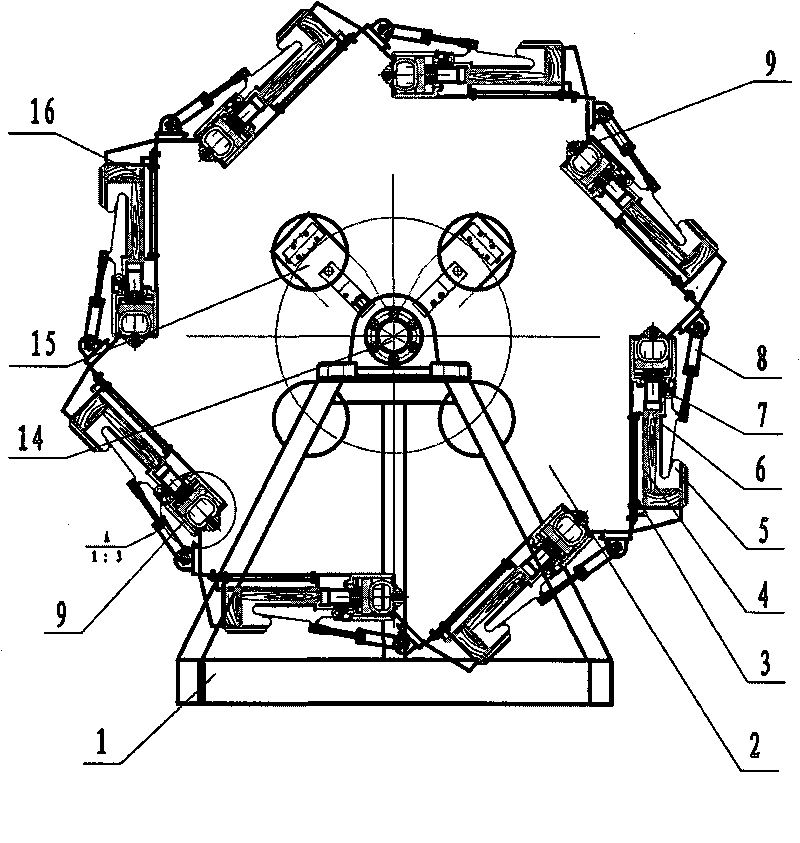

[0023] Example 2, see image 3 , with embodiment 1, difference is that rotary table 2 is 8, and what form is the airbag type multi-function plank splicing machine of eight sides workbench.

[0024] The airbag-type multifunctional plank splicing machine of the present invention is a polygonal rotating workbench composed of two to eight frame-pressing doors, the main shafts at both ends are supported on the frame, and the pneumatic indexing and rotating mechanism is used to rotate in one direction. The operator can press the button of the pneumatic control station on the frame to perform automatic rotation, inching rotation and emergency stop respectively. Each time the automatic rotation button is pressed, the processing station automatically rotates to the next worktable. The rotation angle is obtained by setting the indexing angle according to the number of worktables, and the pneumatic limit switch is assisted to ensure the positioning accuracy. After stopping, the pneumati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com