Swinging bag-type dust collector

A bag filter and swing type technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of bag damage, affecting the service life of the bag, etc., to achieve simple structure, improve dust removal efficiency, improve The effect of cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

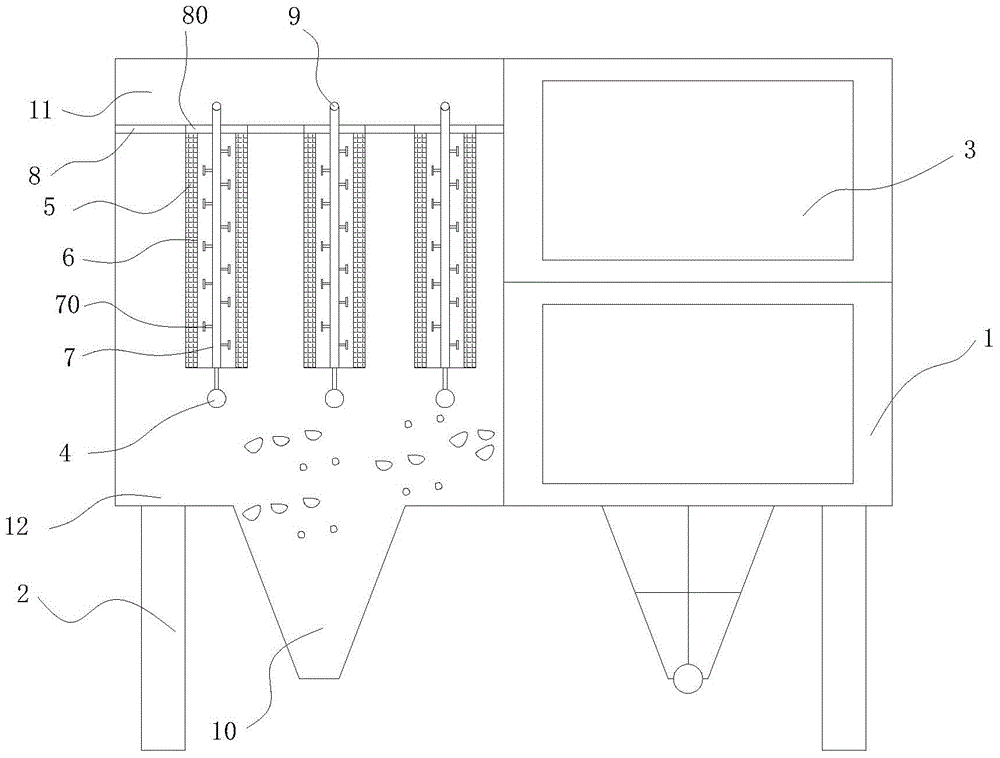

[0011] The invention as figure 1 As shown: The bag filter is set in the collection box 1, the collection box 1 is set on the column 2, the bottom of the collection box 1 is a collection hopper 10 for collecting dust, and the bag filter includes A cloth bag 5 and a ring frame 6, the cloth bag 5 is sleeved on the ring frame 6; the collection box 1 has a partition 8 that divides the collection box 1 into an upper cavity 11 and a lower cavity 12 A plurality of bag holes 80 are evenly distributed on the partition 8, and the bag 5 communicates with the bag holes 80 and is arranged in the lower cavity 12;

[0012] The upper cavity 11 of the collection box 1 is provided with several crossbeams 9, and the evenly distributed connecting rods 7 are movable on the crossbeams 9, and the connecting rods 7 are arranged in the ring-shaped framework 6. The bottom of the rod 7 is provided with a counterweight ball 4 .

[0013] Blades 70 are evenly distributed on the connecting rod 7 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com