A tea drying device control system

A technology of a tea drying device and a control system, which is applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problems of reducing production efficiency, production cost, difficult tea turning, quality defects, etc., and achieves easy installation and maintenance, Improved breathability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

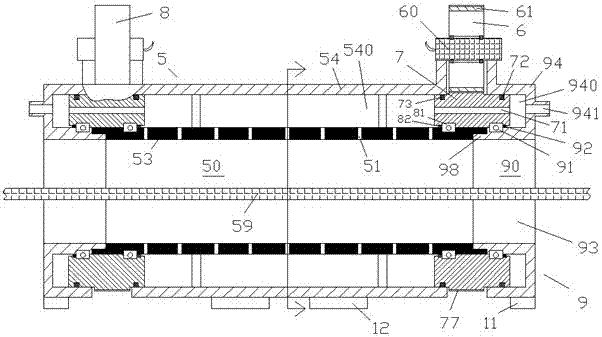

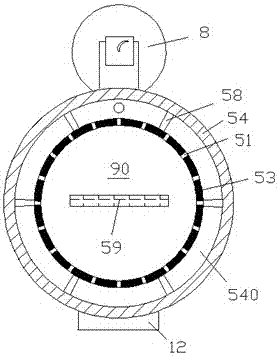

[0011] Combine below Figure 1-3 The present invention will be described in detail.

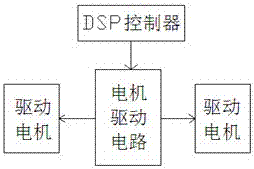

[0012] A tea drying device control system according to an embodiment includes a DSP controller, a motor drive circuit and a tea drying device, the tea drying device includes a structurally symmetrical drying air blowing device 5, the drying The airflow blowing device 5 includes an annular body part 53 provided with an axially extending cylindrical blowing and drying passage 50 and an annular body part 53 supported on the annular body part 53 by a radial support 58 and accommodating the annular body part 53. The shell part 54, the annular body part 53 is provided with a plurality of radial air blowing channels 51 uniformly distributed in the axial direction to input the air flow along the radial direction of the cylindrical blowing and drying channel 50 , the blowing and drying channel 50 is used for passing through the mesh conveyor belt 59 carrying tea leaves, and an annular air distributio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com