Vacuum cleaner nozzle comprising a light source

A vacuum cleaner and light source technology, applied in the installation of suction nozzles and electrical equipment, etc., can solve the problems of cost increase, broken, and cost increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

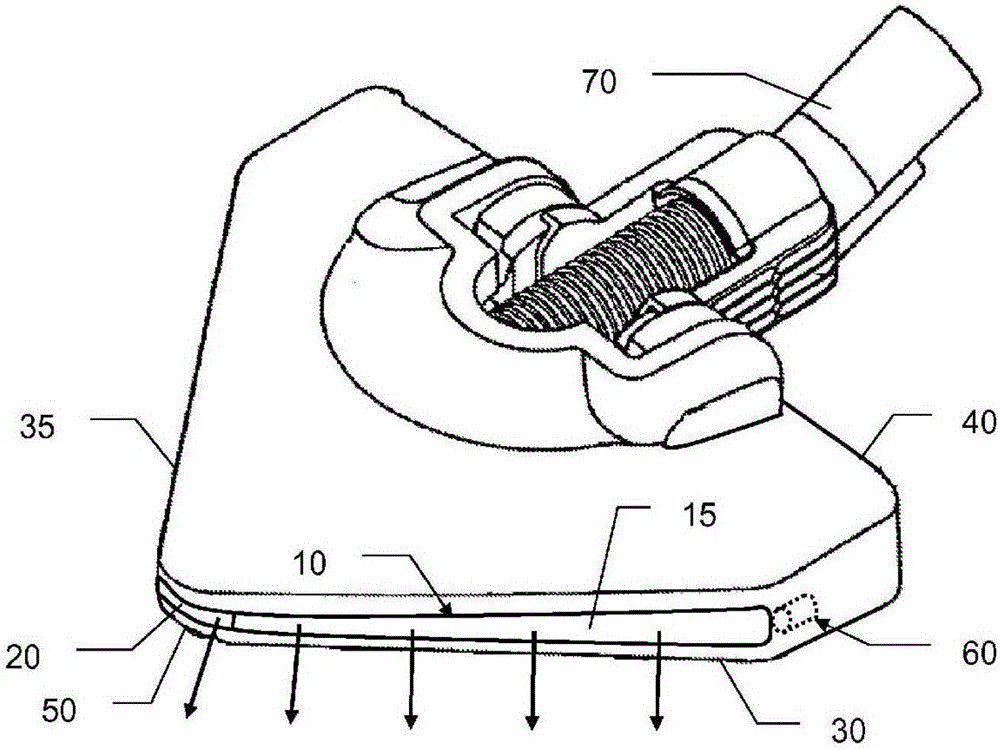

[0035] figure 1 A vacuum cleaner head is shown having a triangular shape. The vacuum cleaner head includes a left front edge 30 and a right front edge 35 which join forwardly to form a tip 50 . At the rear, the leading edges 30 and 35 are connected by a rear face 40 . In addition, the vacuum cleaner head comprises a connection 70 for allowing connection with the duct of the vacuum cleaner.

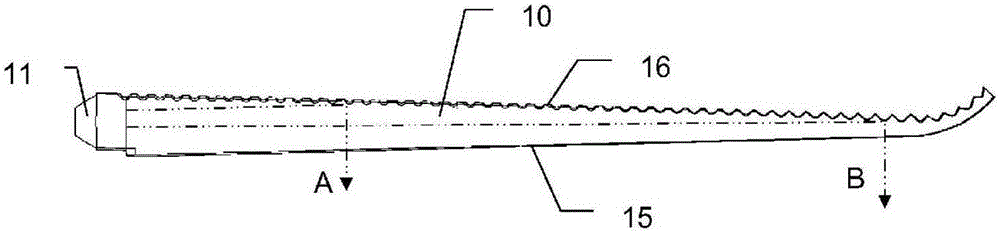

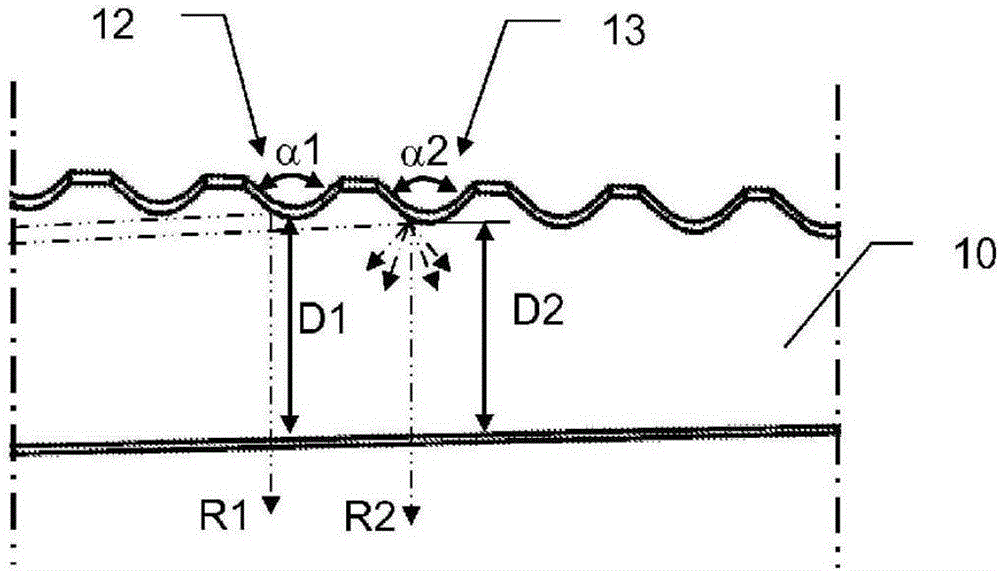

[0036] The vacuum cleaner head comprises a light guide 10 whose outer face forms a projection surface 15 . The projection surface 15 is arranged for projecting a beam of light on the floor to be cleaned as indicated by the arrows shown. The light beam projected by the projection surface 15 is formed by the light source 60, which is shown by dashed lines since it is arranged inside the housing of the main body of the vacuum cleaner head. The light guide 10 collects at one of its ends the light emitted by the light source 60 and transmits this emitted light over its entire length towards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com