A circulating fluidized bed reactor device

A circulating fluidized bed and reactor technology, which is applied in the field of circulating fluidized bed reactor devices, can solve the problems of uncompact reactors, and achieve the effects of low cost, easy manufacture, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

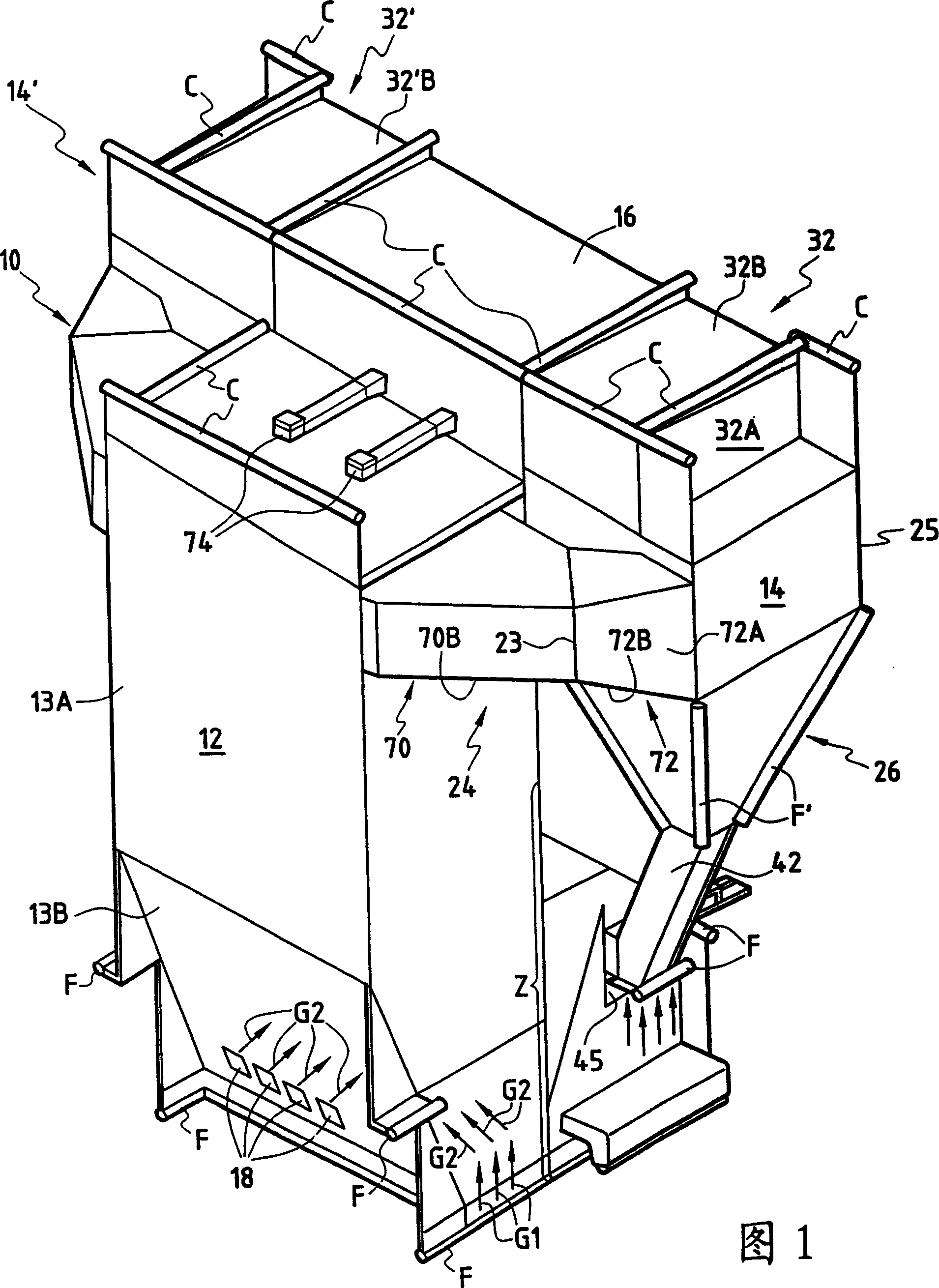

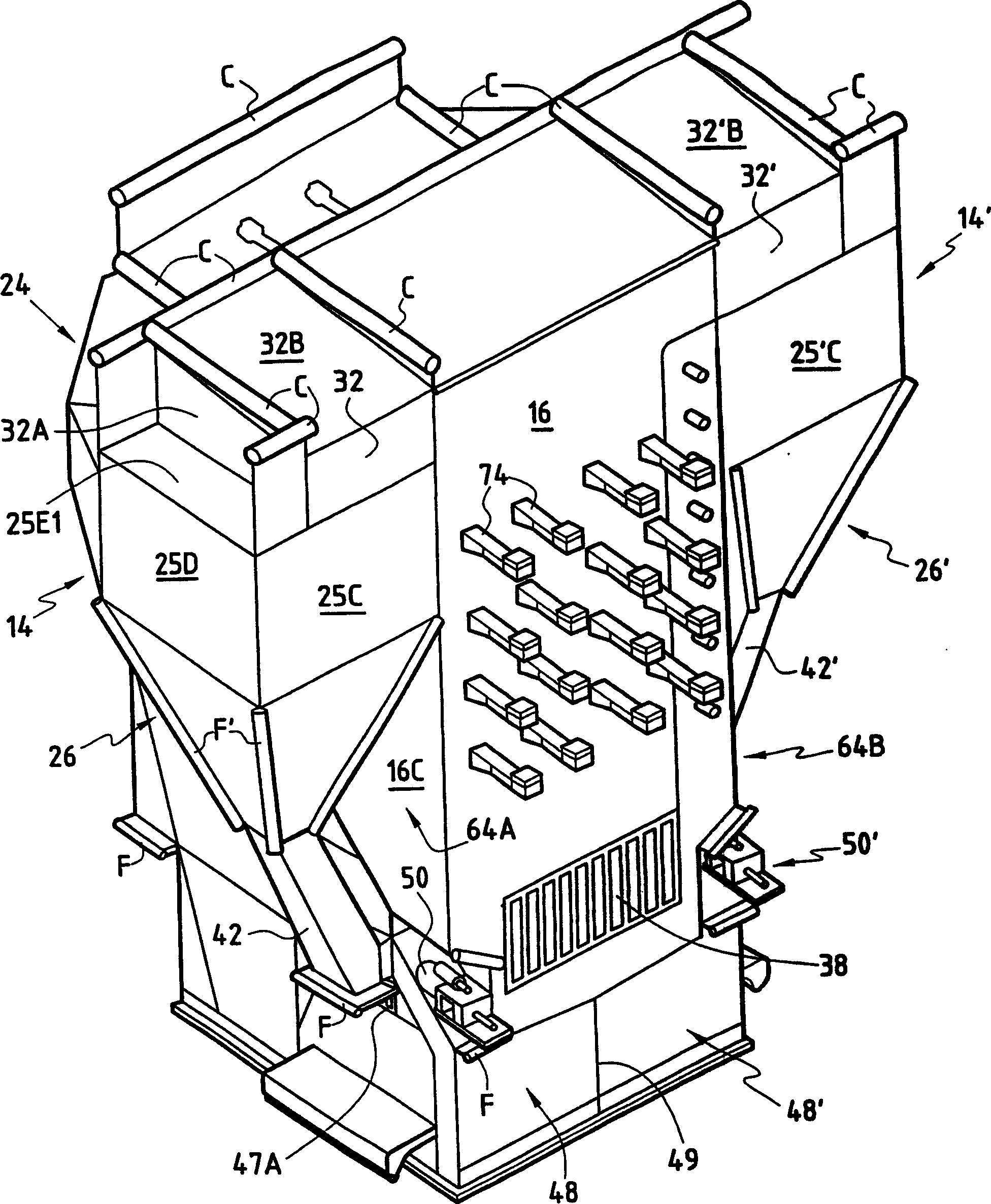

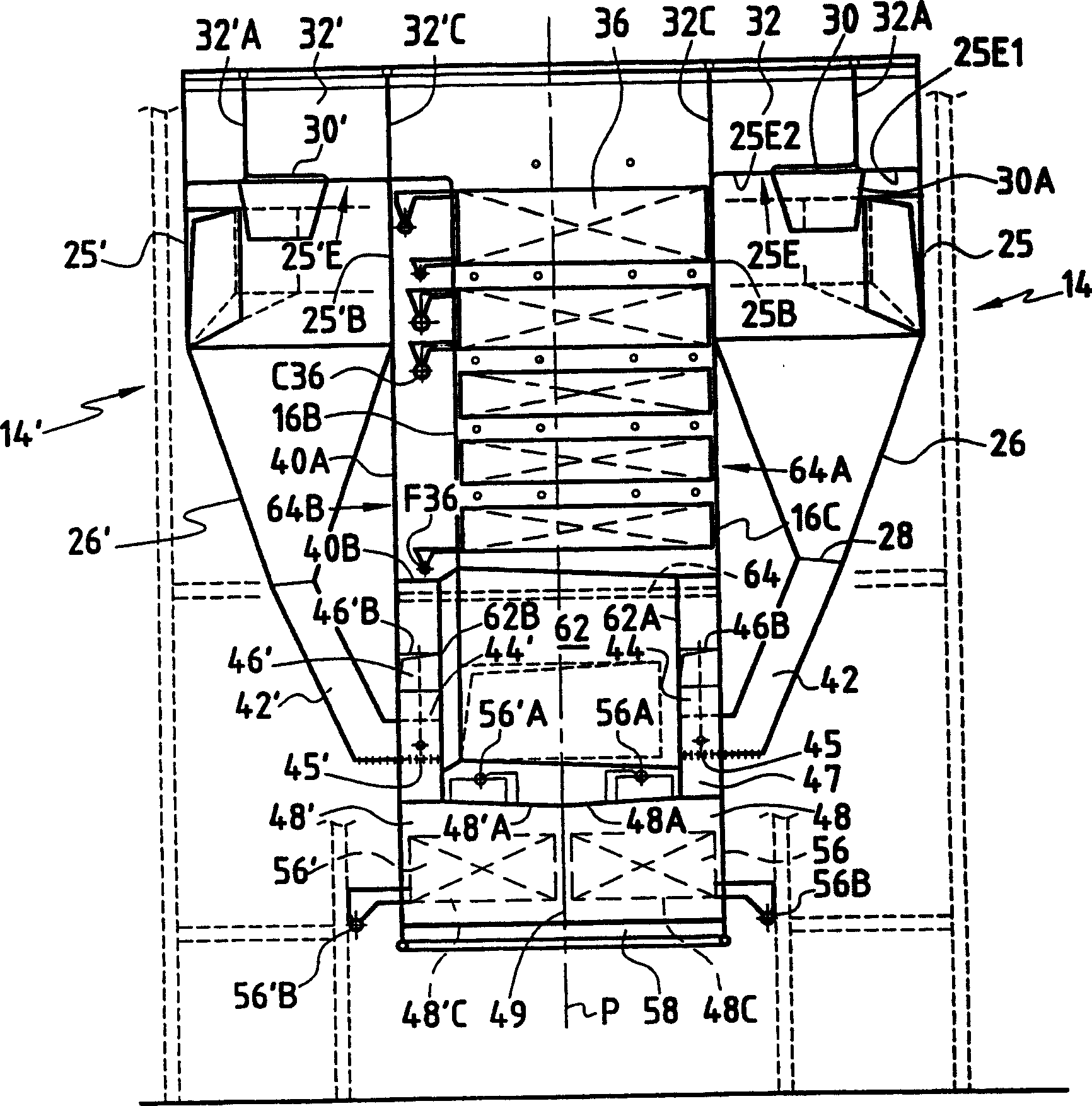

[0059] 1 to 6 show a fluidized bed reactor unit 10 having an upright combustion reaction chamber 12 , a centrifugal separator 14 and a rear channel 16 .

[0060] In the horizontal direction, reaction chamber 12 is delimited by walls 12A, 12B, 12C and 12D. As shown in FIG. 3 , the horizontal section of the reaction chamber 12 is substantially rectangular. In the example shown in the figures, the side walls 12B, 12D and the rear wall 12C are planar walls extending in the vertical direction.

[0061] The front wall 12A has an upper vertical planar portion 13A and a lower planar portion 13B which is inclined relative to the vertical so that the cross-sectional area of the reaction chamber 12 increases upward. The inclination angle α between the lower planar portion 13B and the vertical is approximately 15° to 30° (see Figure 5 ).

[0062] The reaction chamber 12 has several inlets 18 located below one third of the lower planar portion 13B for the entry of solid materials suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com