Multi-channel air particulate matter sampler shunting device and sampler equipped with same

A technology of air particulate matter and diversion device, which is applied in the direction of sampling device, etc., and can solve problems such as error and retained particle sampling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

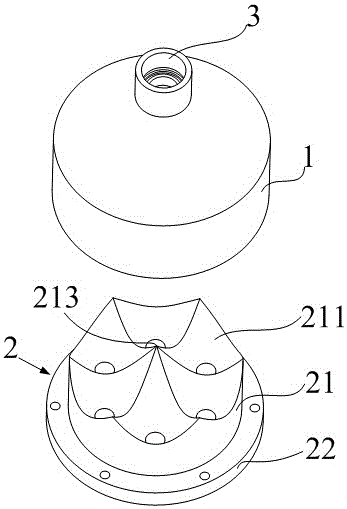

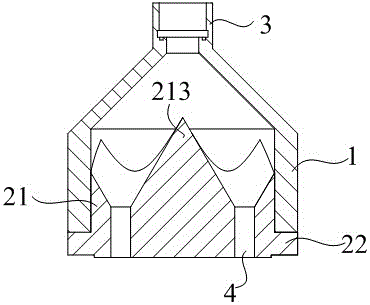

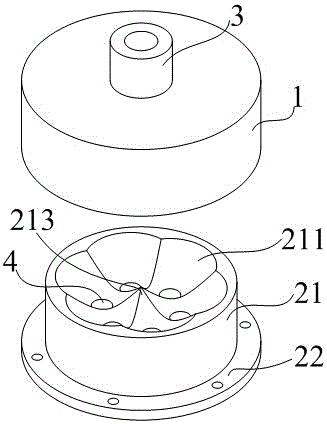

[0029] Embodiment one: if figure 1 , figure 2 As shown, a multi-channel air particle sampler flow diversion device includes an upper end cover 1 and a lower end cover 2, the top end of the upper end cover 1 is provided with an air inlet 3, and the lower end cover 2 includes a cylindrical cylinder 21 and a cylinder located on the cylinder. Flange 22 below 21. Six conical grooves 211 are evenly distributed on the upper surface of the cylinder 21 around the central axis, and the conical surfaces of the conical grooves 211 intersect at one point to form a shunt 213 with a sharp top at the center of the cylinder. The rubber parts of all the tapered grooves 211 form a quincunx groove, which serves as a common inlet for airflow to enter each air path. The bottom of the tapered groove 211 has an air outlet 4, the upper and lower end caps 2 are fastened together, the inner wall of the upper end cap 1 is closely attached to the outer wall of the cylinder 21, and the space between the...

Embodiment 2

[0031] Embodiment two: if Figure 7 and Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the conical surfaces of the tapered grooves 211 do not intersect at one point, but a central platform is formed at the center of the cylinder 21, and the central platform is further cut into a conical shape. , that is, a tip-shaped split body 213 is obtained.

Embodiment 3

[0032] Embodiment three: as Figure 9 and Figure 10 As shown, a multi-channel air particle sampler flow diversion device includes an upper end cover 1 and a lower end cover 2, the top end of the upper end cover 1 is provided with an air inlet 3, and the lower end cover 2 includes a cylindrical cylinder 21 and a cylinder located on the cylinder. Flange 22 below 21. The cylinder 21 has six tapered grooves 211 evenly distributed around the central axis, and the conical surfaces of the tapered grooves 211 intersect at one point. The bottom of the tapered groove 211 has an air outlet 4, the upper and lower end caps 2 are fastened together, the inner wall of the upper end cap 1 is closely attached to the outer wall of the cylinder 21, and the space between the upper and lower end caps 2 is sealed to form a distribution chamber. The flange 22 is provided with a threaded hole, and the lower end of the side wall of the upper end cover 1 is provided with a threaded groove correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com