flow distribution device

A technology of distributor, mass flow, applied in the direction of separation method, fluid flow, separation of dispersed particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

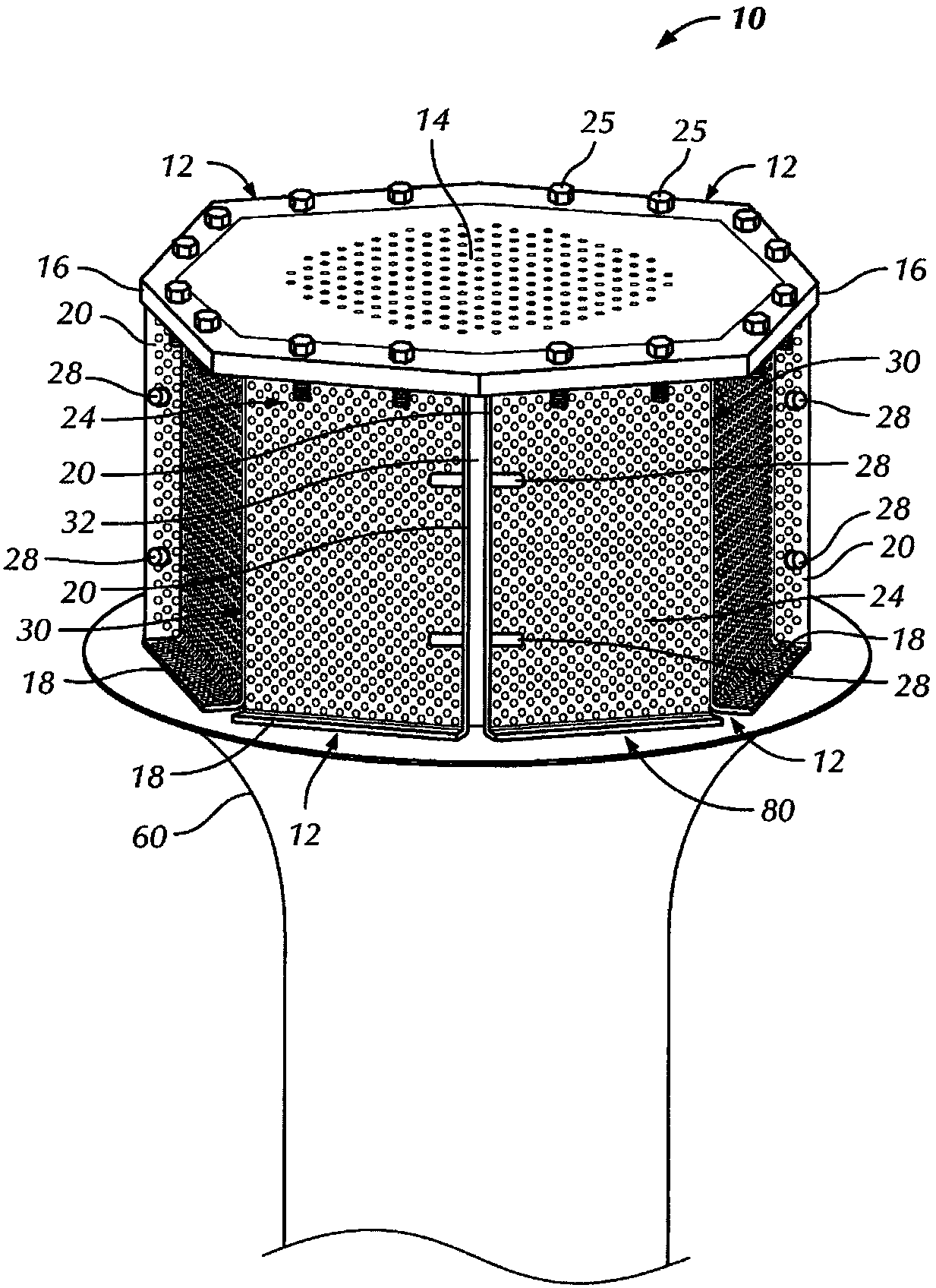

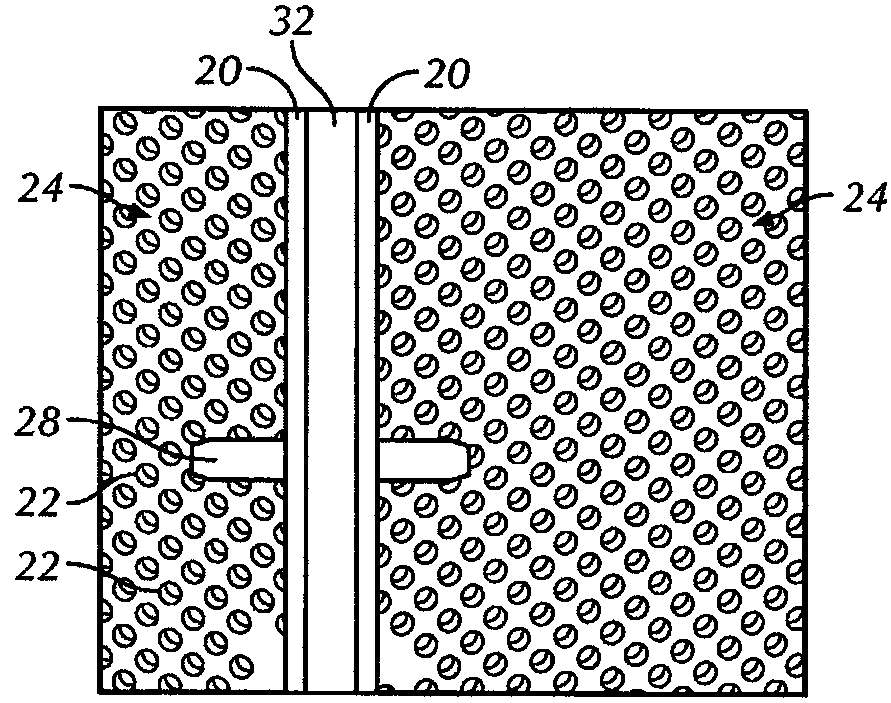

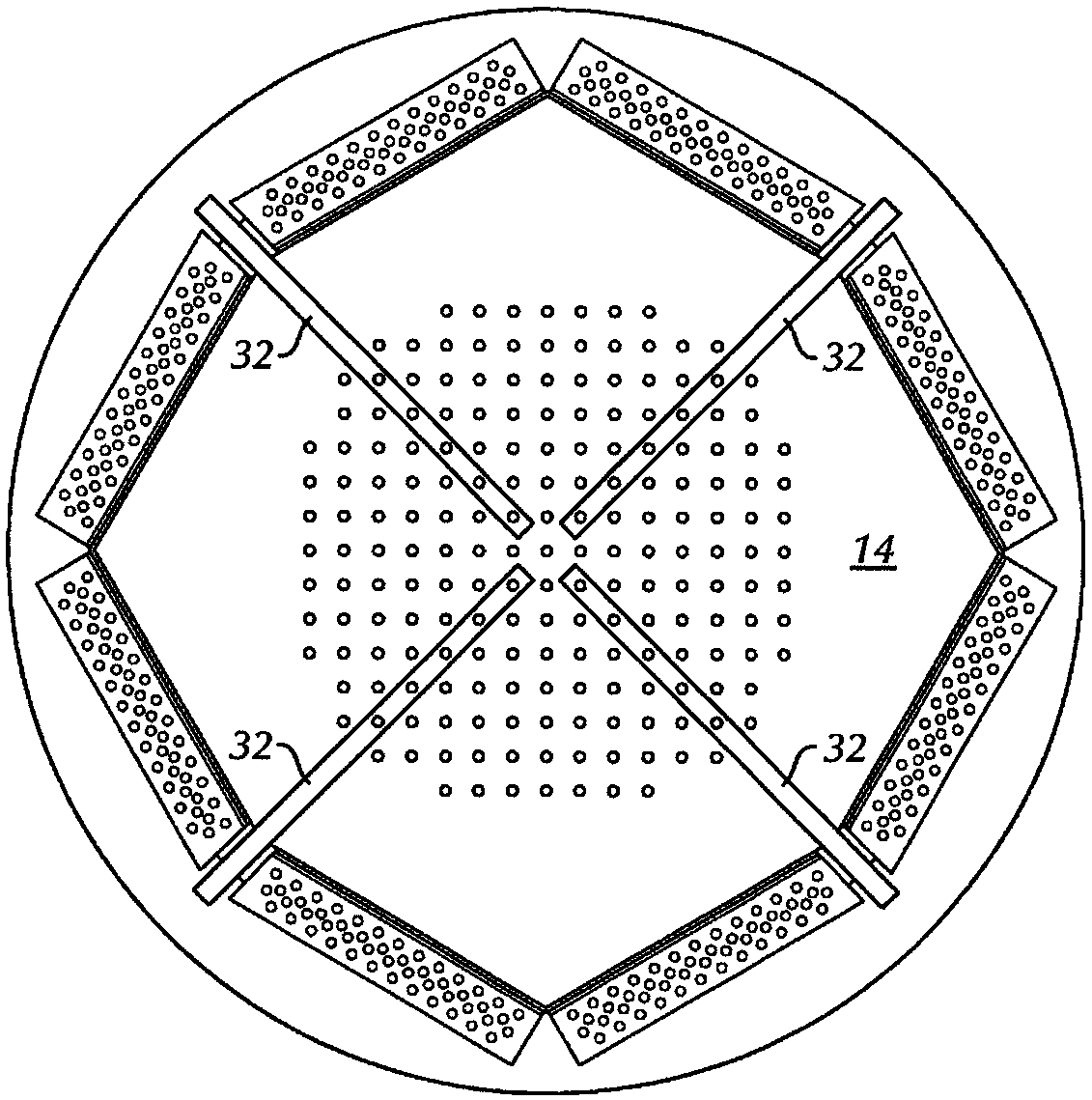

[0087] Computational Fluid Dynamics (CFD) was used to study the flow patterns within the adsorption system produced by the upper and lower distributors of the embodiments disclosed herein. The CFD studies were performed using the following conditions: all porous media were treated as laminar flow zones; the gas mixture (hydrogen and methane) was modeled as an ideal gas; the flow in the inlet and outlet pipes was modeled as turbulent flow using the standard k-e model; the vessel was considered to be in 313K isothermal; constrained porosity, inertial and viscosity tensors are both simulated isotropically (Ergun simplified); the vessel is divided into 8 regions (refer to Figure 7 Figures 1-8 shown in , and methane is linearly removed from the porous media arranged in regions 4-6 with the aid of a negative mass source term.

[0088] The inlet composition included 85.1 wt% methane and 14.9% hydrogen with a mass flow rate of 1.199 kg / s. The density of the mixture is 6.4kg / m 3 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com