A kind of detection method of array substrate

A technology of array substrate and detection method, applied in nonlinear optics, instruments, optics, etc., can solve the problems of insufficient time for design modification, long period, low TFT switching threshold current level, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

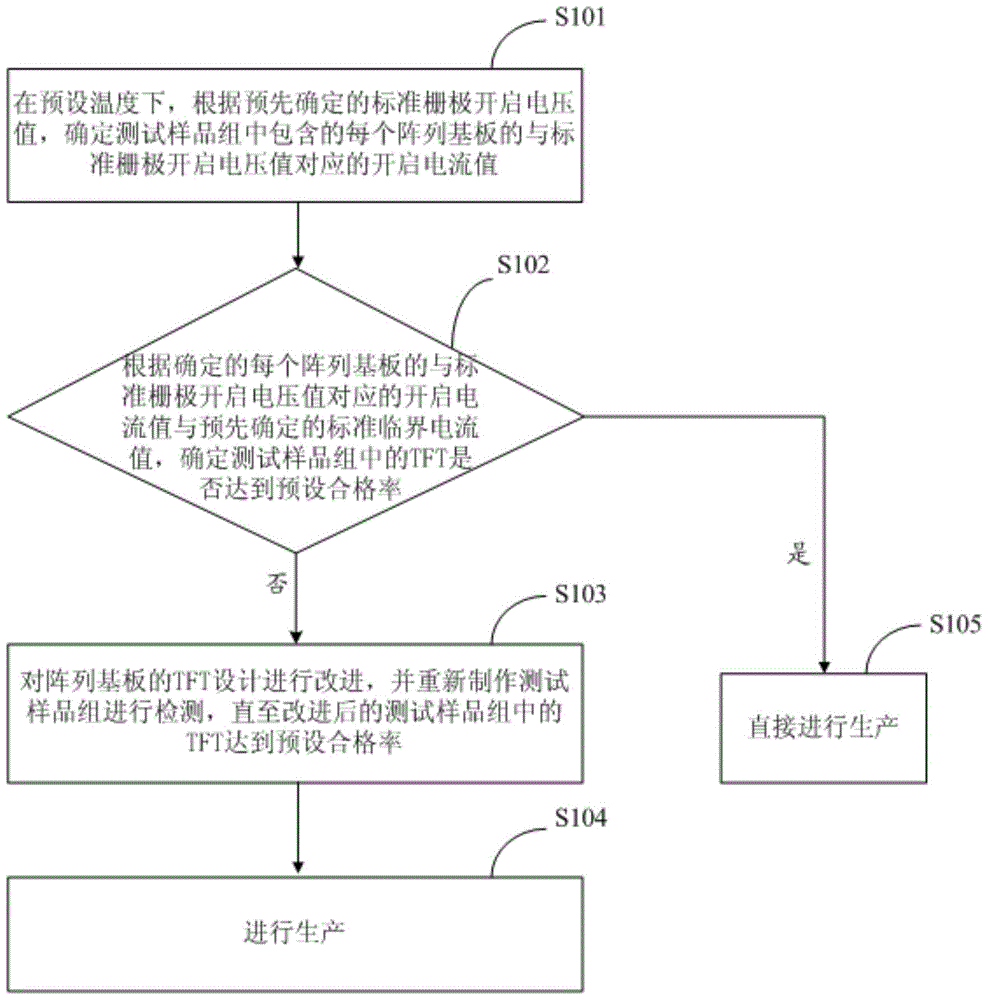

[0038] The specific implementation manner of the detection method for the array substrate provided by the embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0039] An embodiment of the present invention provides a detection method for an array substrate, such as figure 1 As shown, the following steps may be included:

[0040] S101. Determine the turn-on current value corresponding to the standard gate turn-on voltage value of each array substrate contained in the test sample group according to the predetermined standard gate turn-on voltage value at a preset temperature;

[0041] S102. According to the determined turn-on current value corresponding to the standard gate turn-on voltage value of each array substrate and the predetermined standard critical current value, determine whether the TFTs in the test sample group reach the preset pass rate; if not reach the preset When the pass rate is high, step S103 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com