Fresh food pick-up machine

A self-pickup and fresh food technology, which is applied in the direction of instruments, coin-operated equipment for distributing discrete items, coin-operated equipment for distributing discrete items, etc. Troublesome problems such as goods, to achieve the effect of reducing the generation of kitchen waste, efficient delivery, and reducing delivery costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

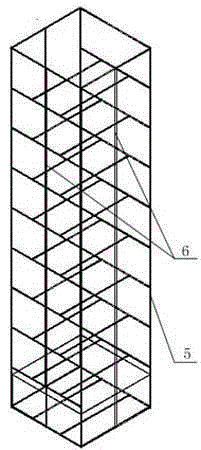

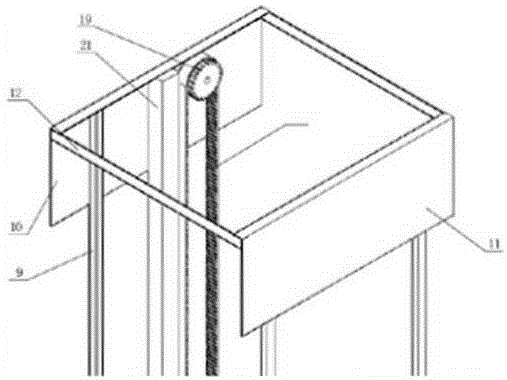

[0027] Such as figure 1 -7, figure 1 0, A kind of fresh self-lifting machine, using a brand-new frame structure, including the cabinet body 1 and the cabinet door set on one side of the cabinet body, the cabinet body is equipped with a cargo supply unit, a pick-up unit, a delivery unit, a barcode scanning module 2, a refrigeration system, a temperature control module, Camera display communication module 3, control system, the goods supply unit is arranged on both sides of the cabinet body, the pick-up unit is arranged between the two goods supply units, and is arranged along the height direction of the cabinet body, the delivery unit, barcode scanning module 2 , camera and display communication modules 3 are all arranged on the upper top plate 4 of the cabinet. It is a device that automatically picks up goods from both sides in the middle and then ships from the top, and can be refrigerated and kept fresh for 24 hours to realize the items ordered by users, such as semi...

Embodiment 2

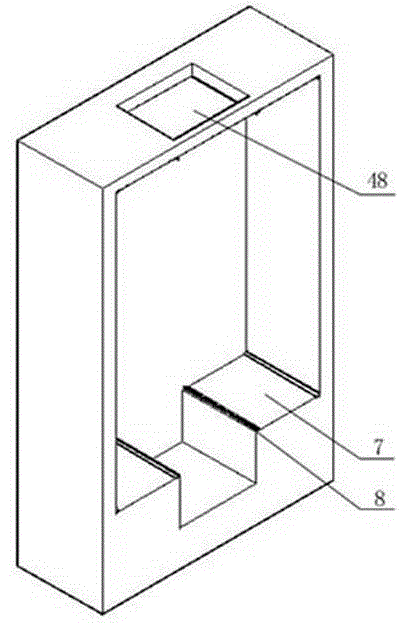

[0035] Such as Figure 8 As shown in -9, the overall structure of this embodiment is the same as that of Embodiment 1, the difference is that in this embodiment, at least two groups of item grids are respectively arranged on the left and right sides of the cabinet, therefore, the fresh self-lifting machine The mobile mechanism also includes a front and rear movement mechanism, and the front and rear movement mechanism includes a rectangular iron plate 42 arranged on the inverted L-shaped support and a sensor stopper arranged under the middle part of the rectangular iron plate. The third slide rail 43 below the fluent bar and the third slide block 44 arranged on the third slide rail drive the third motor 45 and the third synchronous wheel 46 of the third slide block, and the third synchronous wheel 46 arranged on the third synchronous wheel Three synchronous belts 47, the third slide rail is arranged along the direction of the front and rear walls of the cabinet.

[0036] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com