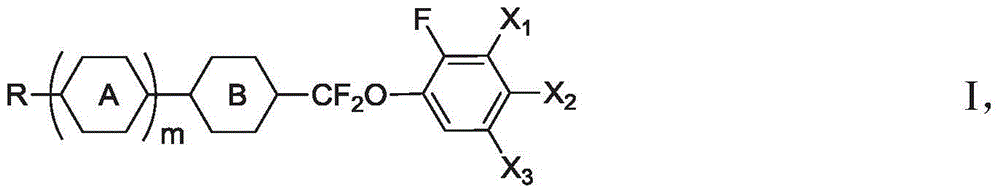

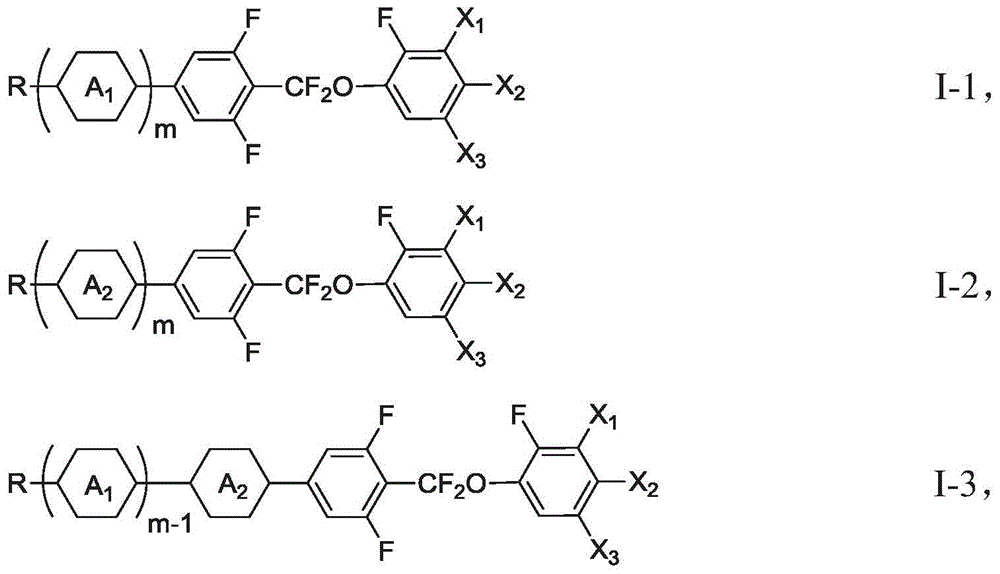

Liquid crystal compound with 2-fluorophenyl and difluoromethyleneoxy group and its preparation method and application

A difluoromethylene oxide, liquid crystal compound technology, applied in chemical instruments and methods, ether preparation, organic chemistry, etc., can solve problems such as the drop of clearing point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

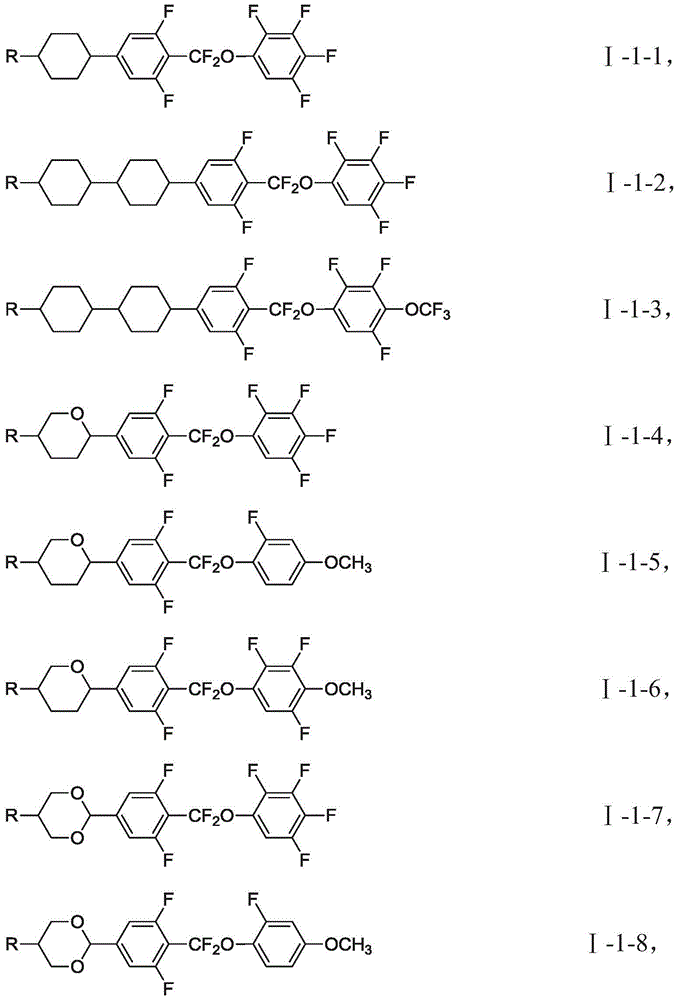

[0129] Preparation of liquid crystal compounds shown in formula I-1-1-1, the structural formula is as follows,

[0130]

[0131] The synthetic route is,

[0132]

[0133] Specifically, it includes the following five steps from Step 1-1 to Step 1-5,

[0134] 1-1) Add 0.2mol Dissolve in 100ml tetrahydrofuran for use, add 0.22mol magnesium chips and 100ml tetrahydrofuran to a 500ml three-necked bottle and heat to reflux, add a small amount of the above solution to prepare the Grignard reagent, keep reflux and add dropwise after the reaction is initiated, if it is difficult to initiate the reaction, add iodine Initiated by pellets or ethyl bromide, and refluxed for 1 hour after the addition, to obtain After the Grignard reagent, drop 0.2mol Addition, reflux for 1 hour after addition. The viscous reaction solution was obtained, then poured into 200ml of ice water and 20ml of hydrochloric acid, hydrolyzed under stirring, separated, extracted, washed with water, evaporat...

Embodiment 2

[0140] Preparation of liquid crystal compounds shown in formula I-1-2-1, the structural formula is as follows,

[0141]

[0142] According to the same steps as in Example 1, only the replace with A liquid crystal compound represented by formula I-1-2-1 was obtained.

Embodiment 3

[0144] Preparation of liquid crystal compounds shown in formula I-2-1-1, the structural formula is as follows,

[0145]

[0146] The synthetic route is,

[0147]

[0148] It specifically includes the following four steps from Step 2-1 to Step 2-4,

[0149] 2-1) Add 0.11mol Dissolve in 80ml of toluene, 20mL of ethanol, and 70mL of water, start stirring and add 0.13mol sodium bicarbonate, add 0.4g tetrakis(triphenylphosphine)palladium under nitrogen protection, heat to reflux, stop heating to keep the reaction system under slight reflux, add 50mL dropwise 16.4 g (0.1 mol) of the mixed solution dissolved in ethanol, the reaction solution turned light yellow, and was heated under reflux for 4 hours after the dropwise addition. Cool down to 50°C, pour into 100ml of water, separate the organic layer, extract, wash with water, evaporate the solvent, and recrystallize the obtained product with ethanol to obtain 18.6g of white crystals Yield 80%.

[0150] 2-2) Step 2-1) to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com