Universal LED headlamp

A general-purpose technology for headlights, applied in the field of headlights, can solve the problems of large overall size, high cost and high energy consumption of headlights, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings of the description.

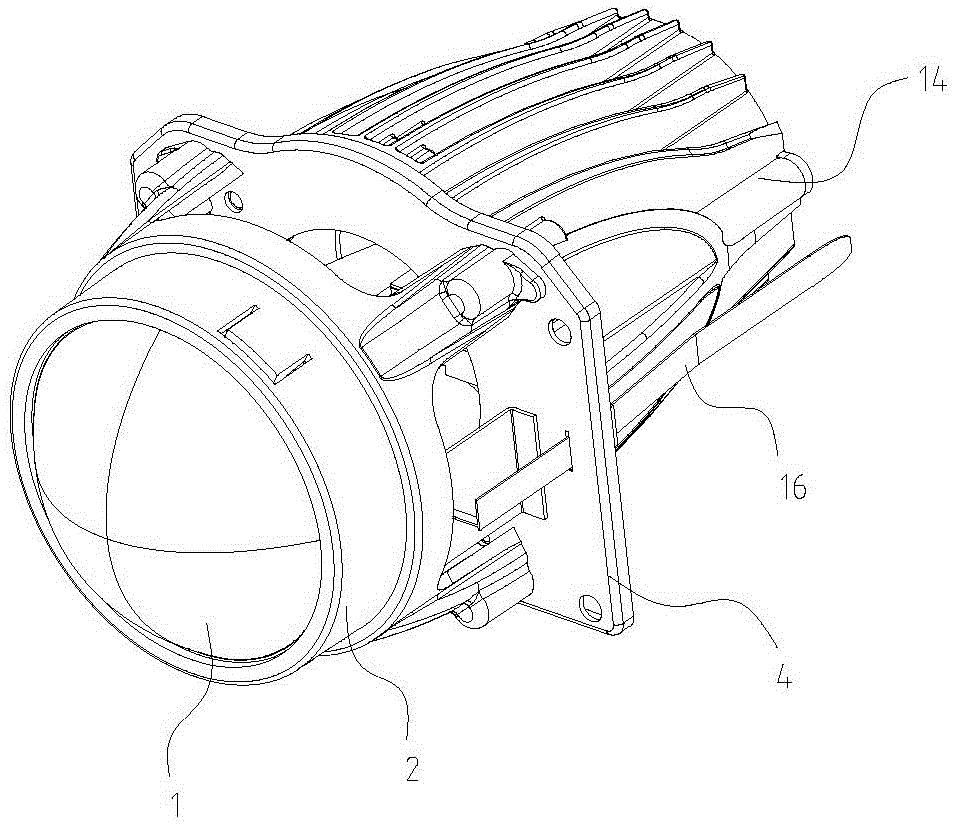

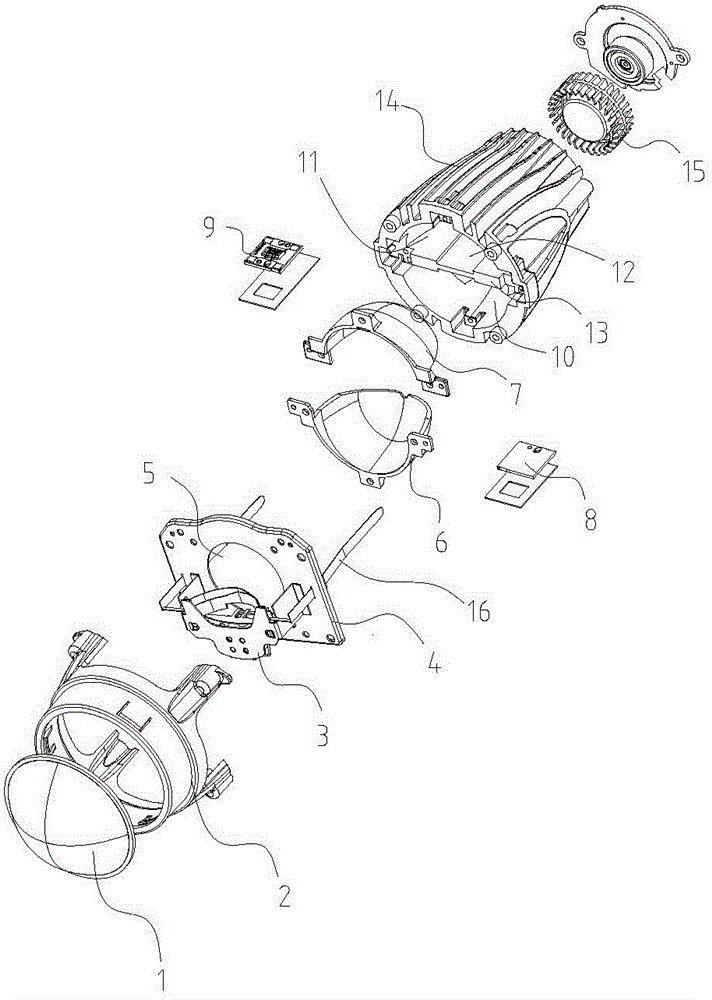

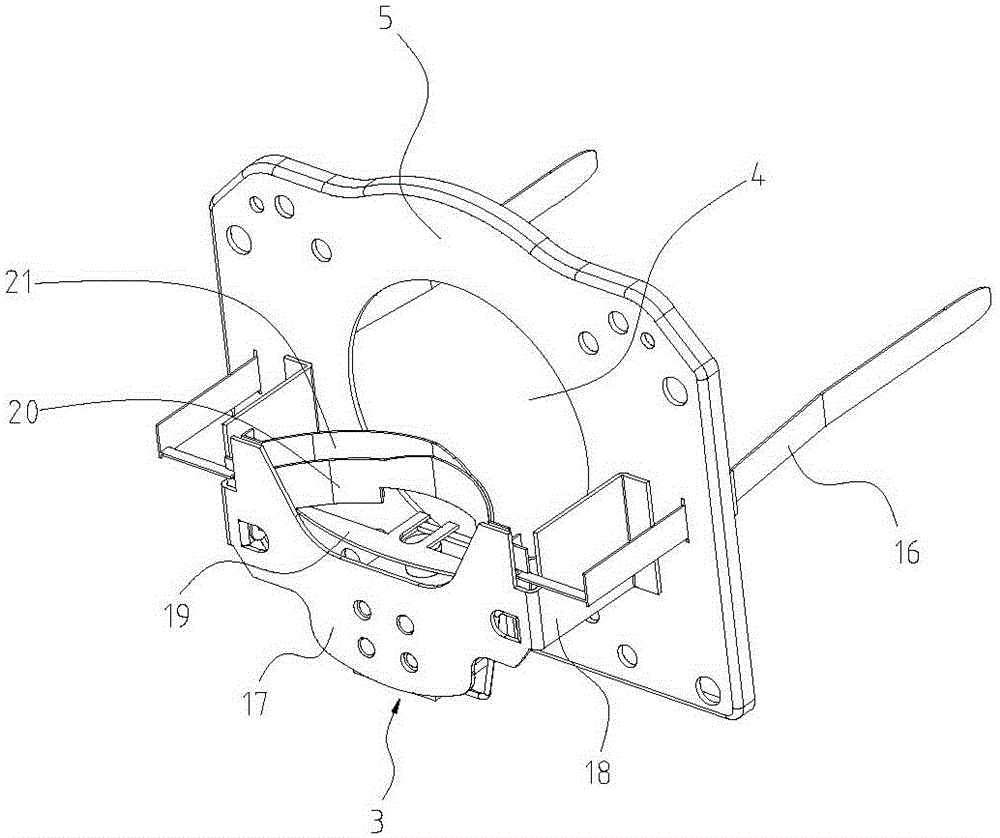

[0025] Such as figure 1 , 2 As shown, a general-purpose LED headlight includes an LED substrate 13, a first LED light source 9 located on the upper surface of the LED substrate 13, a second LED light source 8 located on the lower surface of the LED substrate 13, and a first LED light source located on the upper surface of the LED substrate 13. The upper reflector 7 for light distribution of the LED light source 9, the lower reflector 6 for light distribution with the second LED light source 8, the radiator 14, the lens 1 and the light blocking mechanism positioned in front of the light source.

[0026] Such as figure 2 As shown, the heat sink 14 has a cup-shaped structure, the surface of the heat sink 14 is provided with a number of cooling fins, the head of the heat sink 14 is provided with a cavity, and the LED substrate 13 is arranged on the I...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap