Automatic guardrail plate stacking device

A guardrail and automatic technology, which is applied in the direction of transportation, packaging, and object stacking, etc., can solve the problems of time-consuming and laborious manual handling, easy injury to workers, poor cooperation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

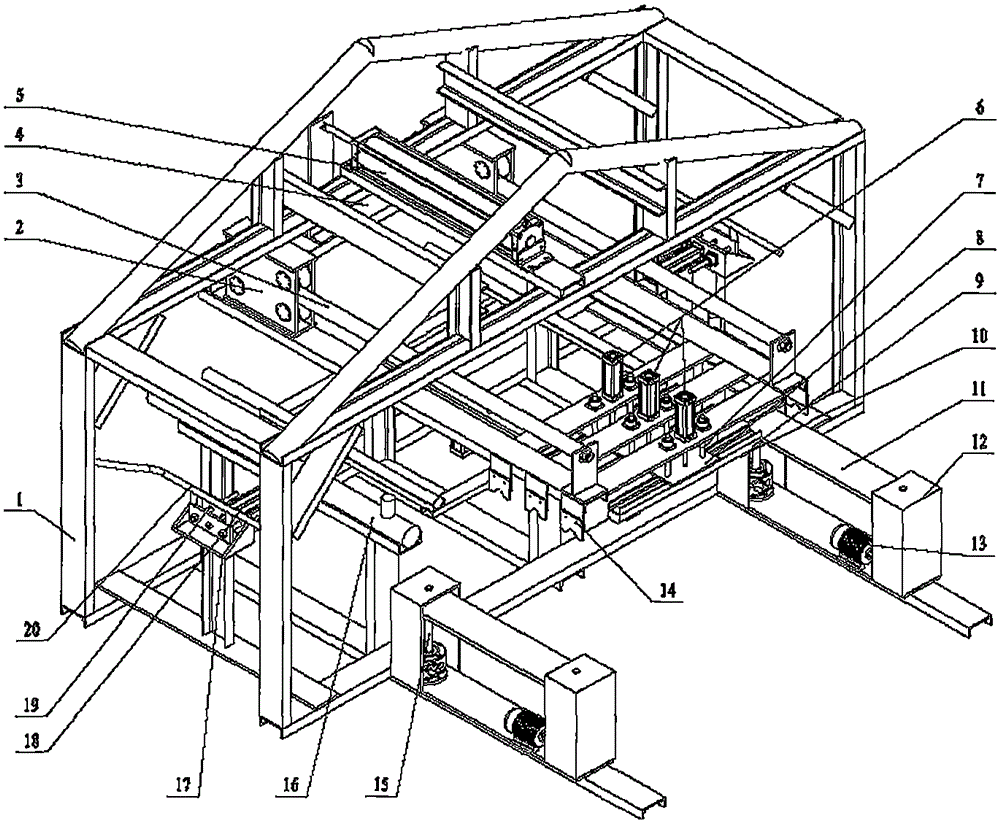

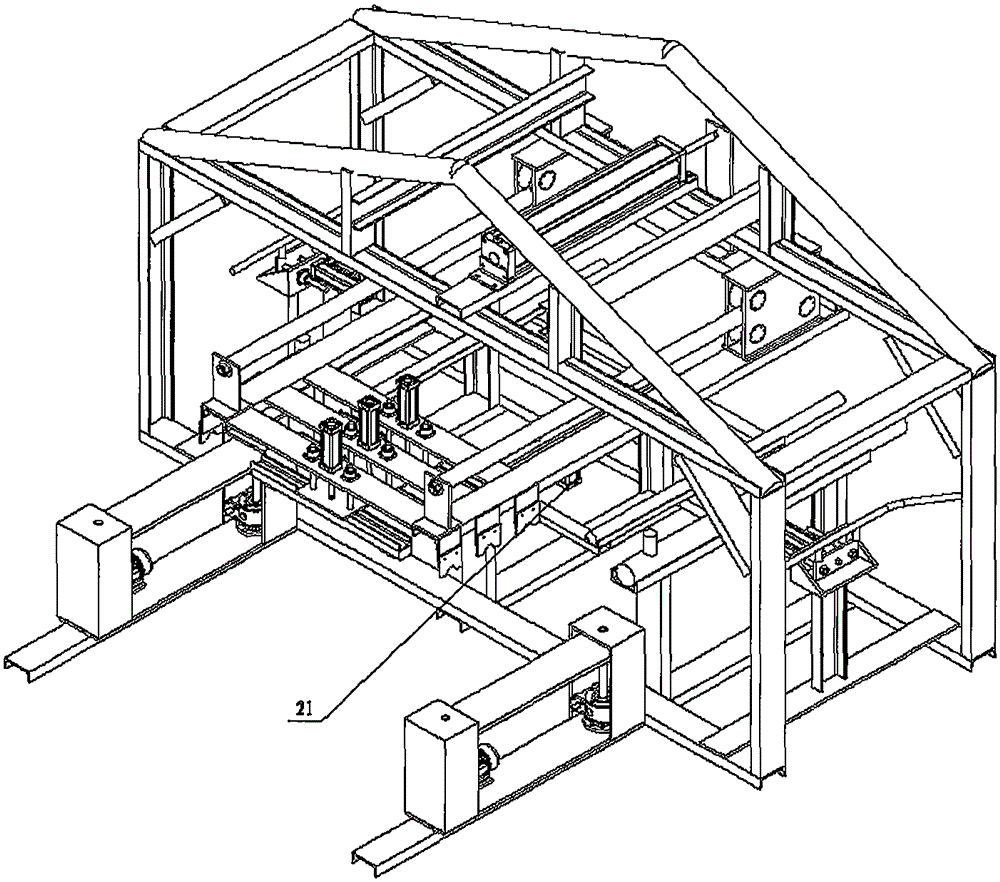

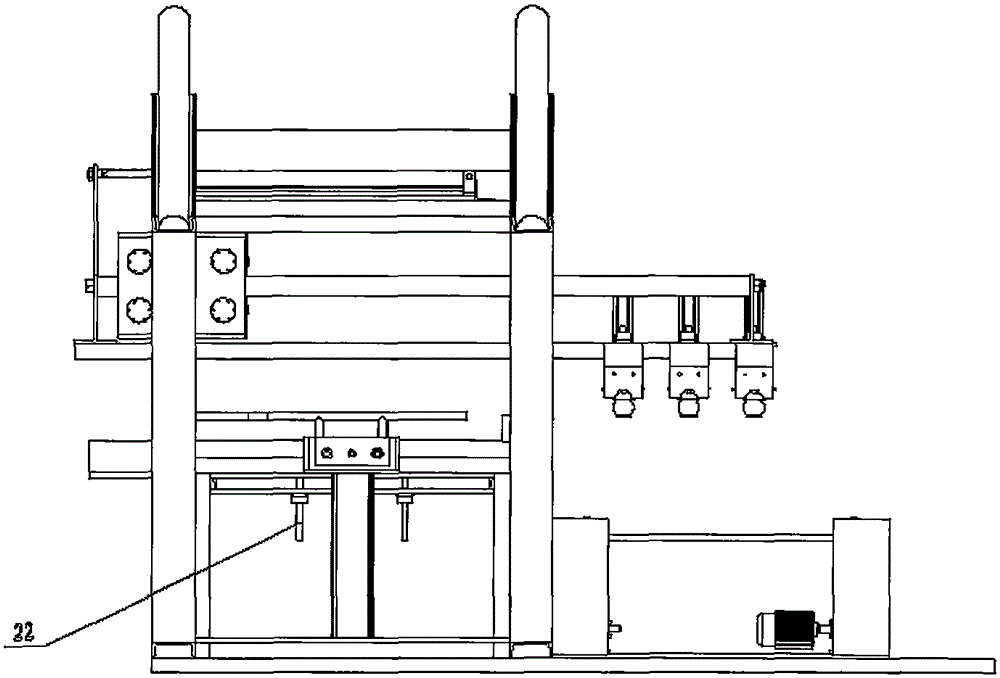

[0008] An automatic stacking guardrail board device is composed of a main support 1, a translation guide 2, a translation guide rod 3, a front and rear translation support 4, a front and rear translation cylinder 5, an up and down translation cylinder 6, an up and down translation guide rod 7, and an up and down translation connecting plate 8, Rubber rod 9, magnet 10, supporting plate 11, shield 12, motor reducer 13, pressure plate 14, lead screw 15, slideway 16, left and right positioning bracket 17, left and right positioning cylinder 18, left and right positioning cylinder guide rod 19, left and right positioning Rod 20, jacking cylinder 21, jacking cylinder guide rod 22, jacking bracket 23, fixed bracket 24, lead screw nut 25, left and right positioning plates 26 are characterized in that: the translation guide 2 is fixed on the main bracket 1, Front and rear translation support 4 is connected with translation guide 2 through translation guide rod 3, front and rear translat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com