Space extrusion normal-pressure accumulating leak detecting system and method

A leak detection and space technology, applied in the field of space extrusion atmospheric pressure cumulative leak detection system, can solve the problems of reduced leak detection efficiency, increase of the minimum detectable leak rate of the leak detection system, leakage, etc., so that the total gas volume does not decrease , Reduce the detectable leak rate and improve the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

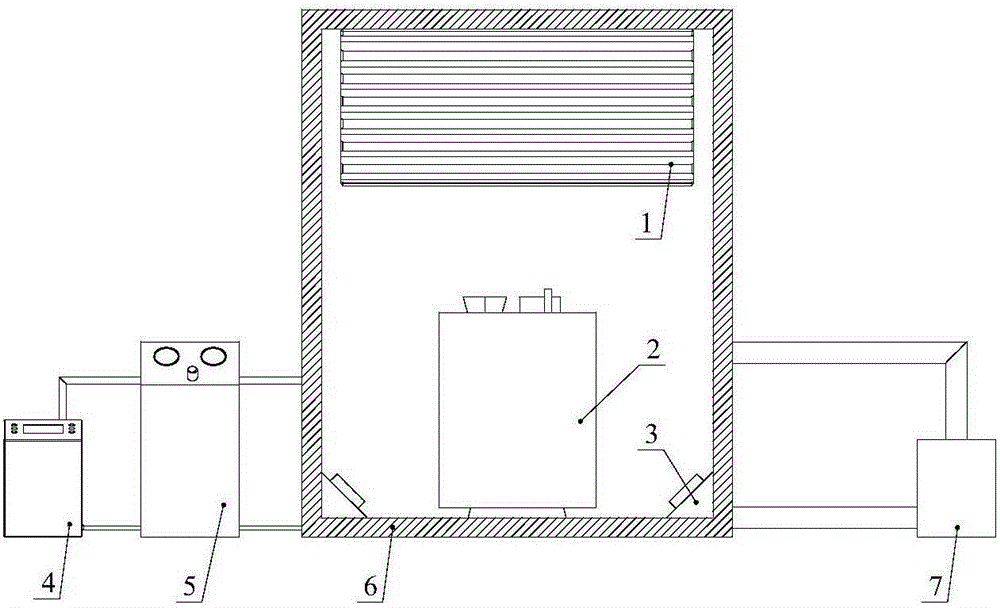

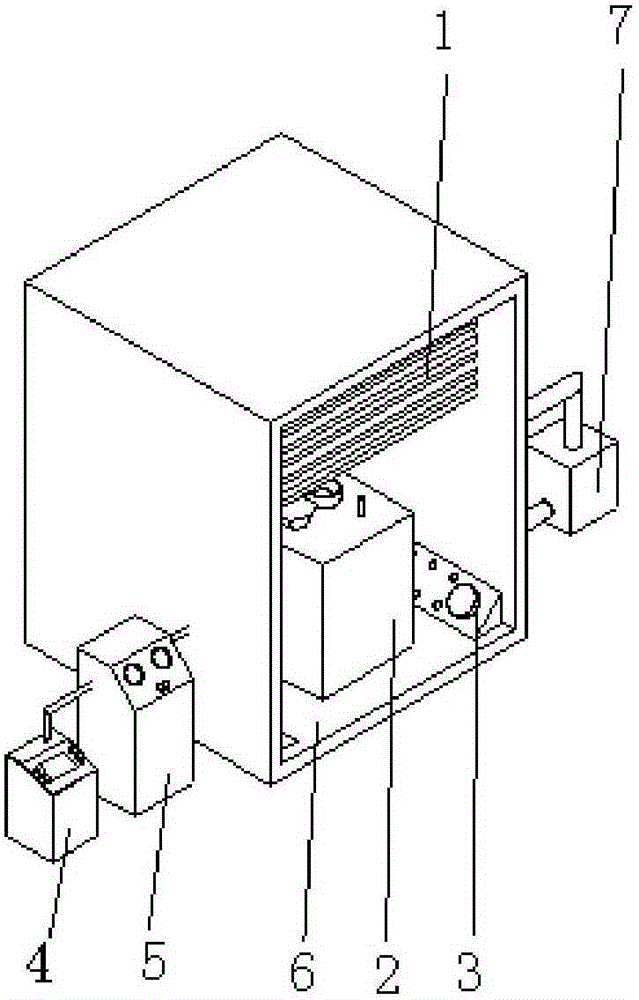

[0088] (1) Install the inspected product filled with the leak-indicating medium in the collection container;

[0089] (2) Install a fixed space extrusion device in the collection container to squeeze out the excess space. The volume of the extrusion space device remains unchanged during the detection period, and the volume of the collection container also remains unchanged;

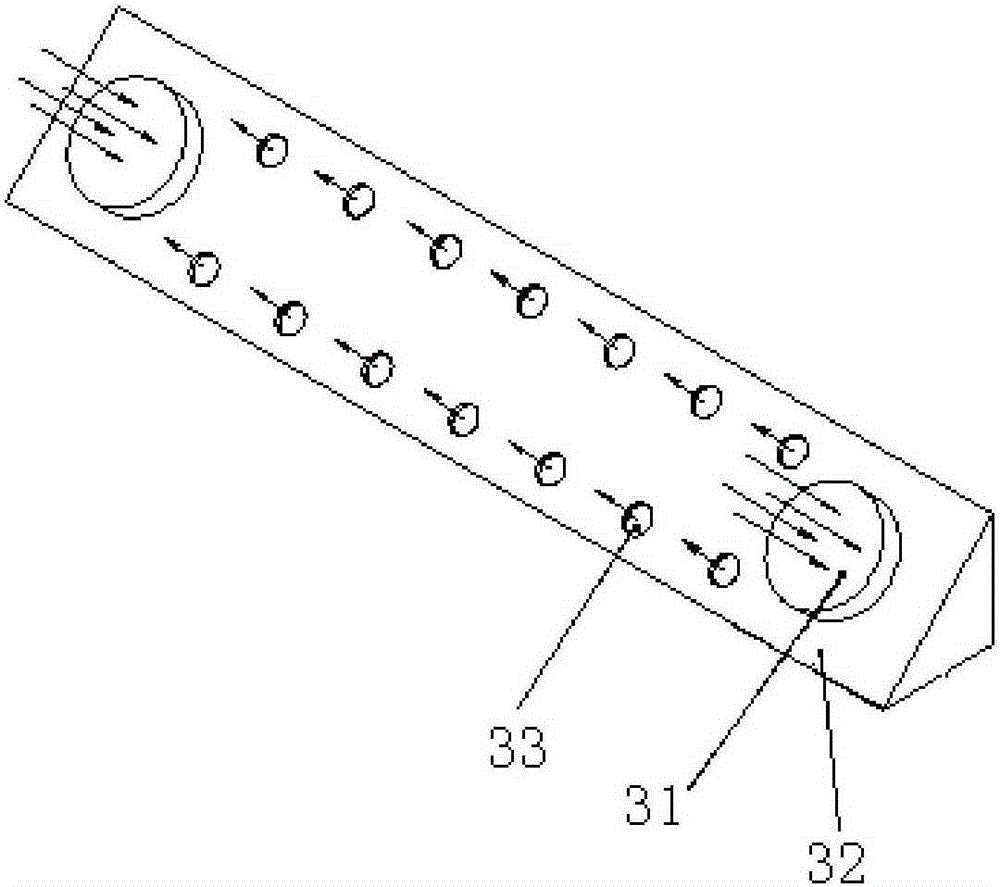

[0090] (3) Seal the collection container, and stir the gas in the collection container in a circular array to form a uniform circulating air, so that the gas in the collector can be mixed quickly and evenly;

[0091] (4) Collect and accumulate the leaking working medium leaked from the inspected product through the collection container, and the minimum accumulation time is calculated according to the following formula:

[0092] t m = I n p c ...

Embodiment 2

[0120] (1) Install the inspected product filled with the leak-indicating medium in the collection container;

[0121] (2) Install a retractable space extrusion device in the collection container, operate and extend the device, and squeeze out the excess space. The volume of the space extrusion device remains unchanged during the detection period, and the volume of the collection container also remains unchanged;

[0122] (3) Seal the collection container, and stir the gas in the collection container in a circular array to form a uniform circulating air, so that the gas in the collector can be mixed quickly and evenly;

[0123] (4) Collect and accumulate the leaking working medium leaked from the inspected product through the collection container, and the minimum accumulation time is calculated according to the following formula:

[0124] t m = I n p ...

Embodiment 3

[0152] (1) Install the inspected product filled with the leak-indicating medium in the collection container;

[0153] (2) Install a fixed space extrusion device in the collection container to squeeze out the excess space. The volume of the extrusion space device remains unchanged during the detection period, and the volume of the collection container also remains unchanged;

[0154] (3) Seal the collection container, and stir the gas in the collection container in a circular array to form a uniform circulating air, so that the gas in the collector can be mixed quickly and evenly;

[0155] (4) Collect and accumulate the leaking working medium leaked from the inspected product through the collection container, and the minimum accumulation time is calculated according to the following formula:

[0156] t m = I n p c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com