Automatic nut replacing mechanism

A nut, automatic technology, applied in the field of automatic nut changing mechanism, can solve the problems of wasting human resources and unfavorable automatic production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

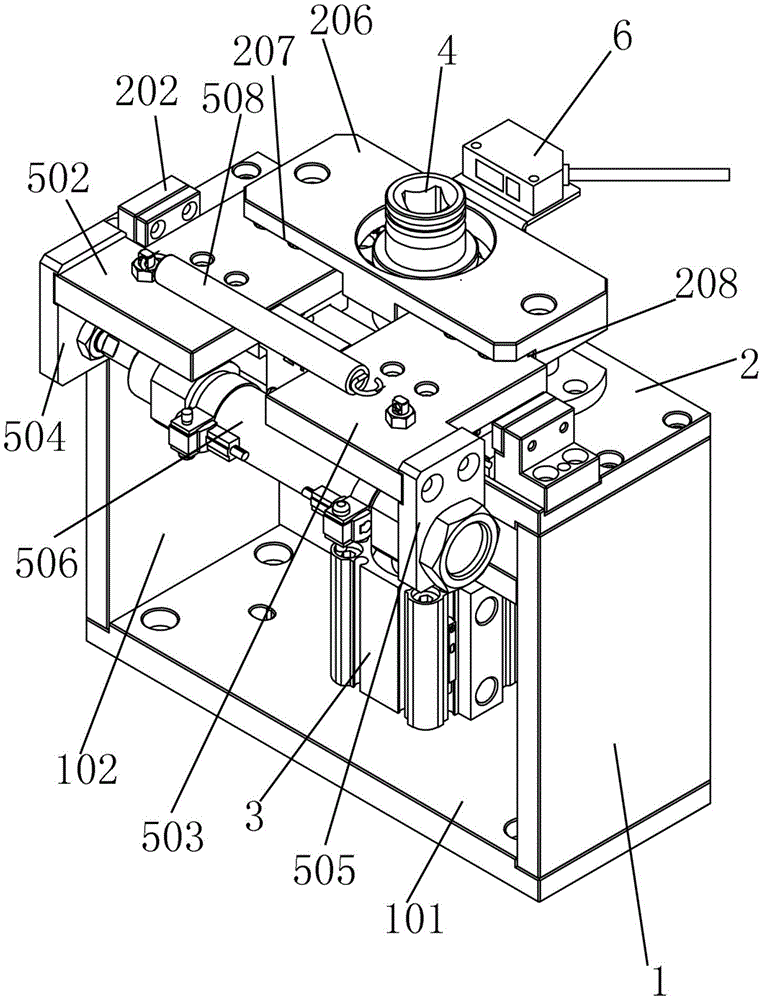

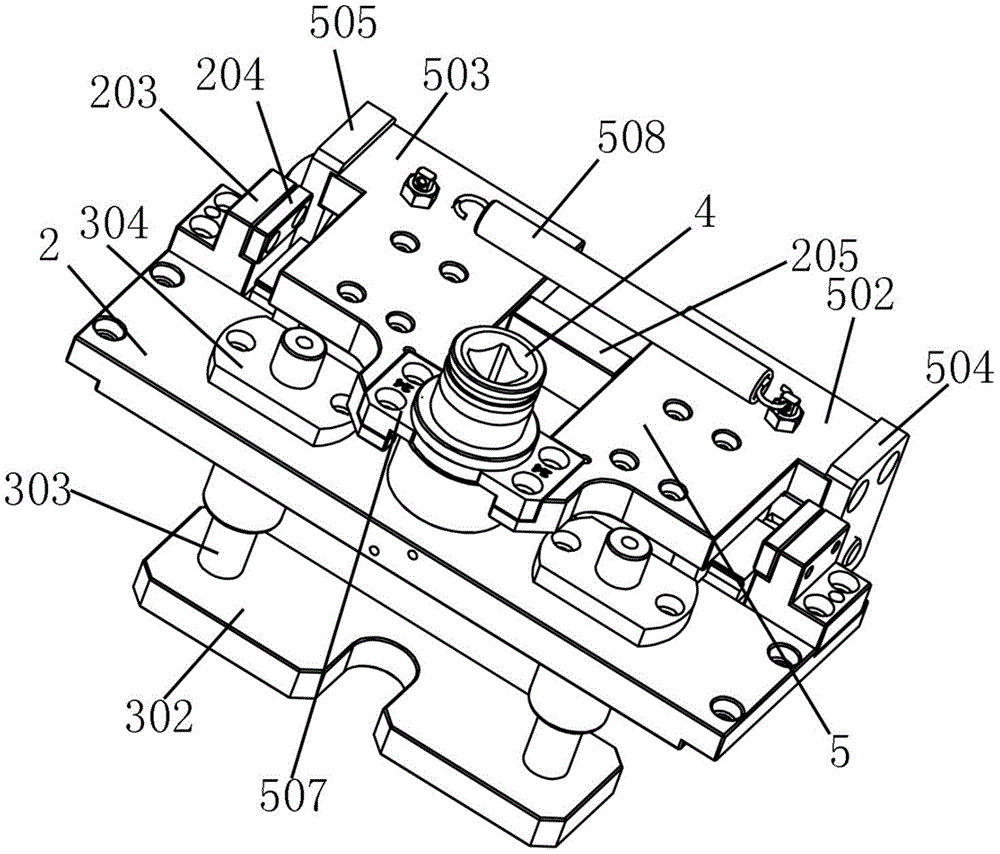

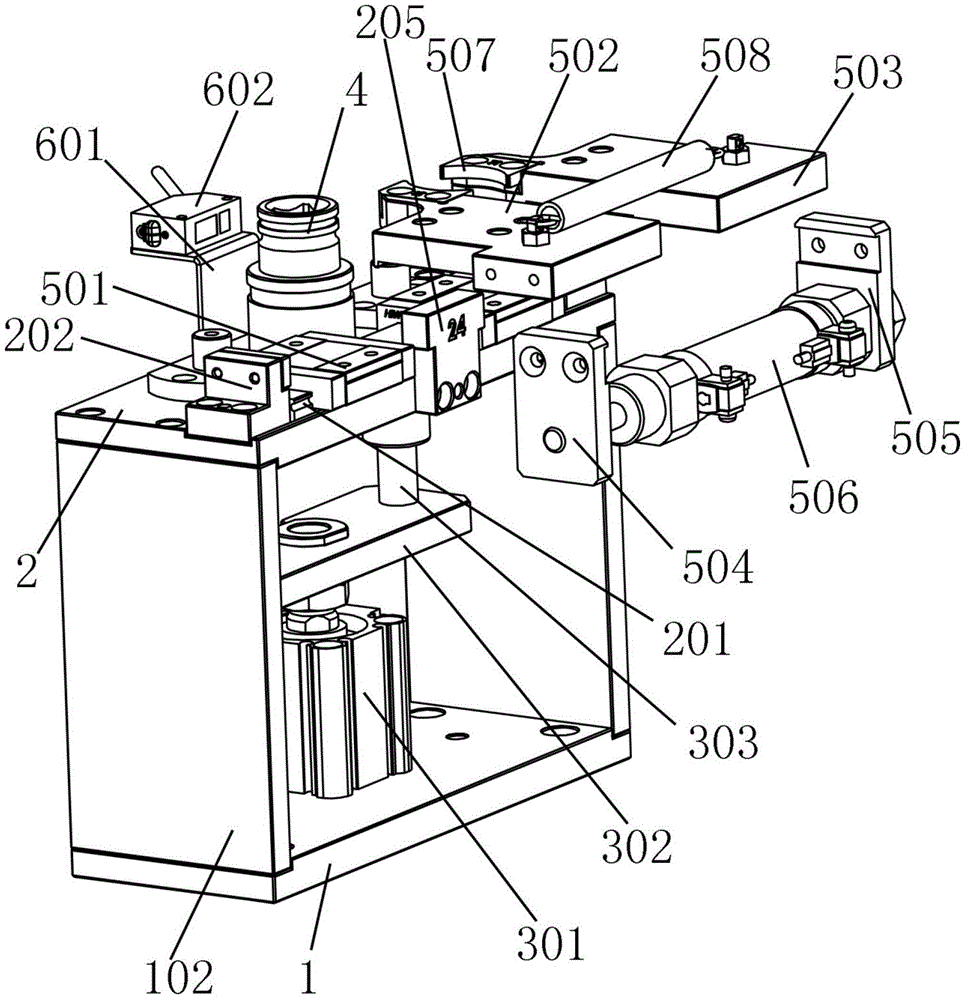

[0029] refer to Figure 1-Figure 3 , the present embodiment provides an automatic nut changing mechanism, including a mounting frame 1, a support seat 2 disposed on the mounting frame 1, a first cylinder assembly 3 disposed on the mounting frame 1 for jacking the support seat 2, The nut bit 4 set on the upper end of the support base 2, the slide rail 201 set on the support base 2, and the splint assembly 5 set on the slide rail 201 for clamping the nut bit 4;

[0030] The mounting frame 1 includes a base plate 101 and vertical plates 102 respectively arranged at the left and right ends of the base plate 101;

[0031] The first cylinder assembly 3 includes a first cylinder 301 fixedly arranged on the bottom plate 101, a cylinder connecting plate 302 connected to the cylinder shaft of the first cylinder 301, and guides connected to the cylinder connecting plate 302 and the support base 2 at both ends respectively. shaft 303;

[0032] Clamping plate assembly 5 comprises the sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com