A temperature controller for an electric iron

A technology of electric iron temperature controller and temperature adjustment device, which is applied in the direction of hand iron, washing device, textile and paper making, etc. It can solve the problems of complex process, high cost, difficult to guarantee product accuracy and stability, and improve the matching rate , Easy and fast assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

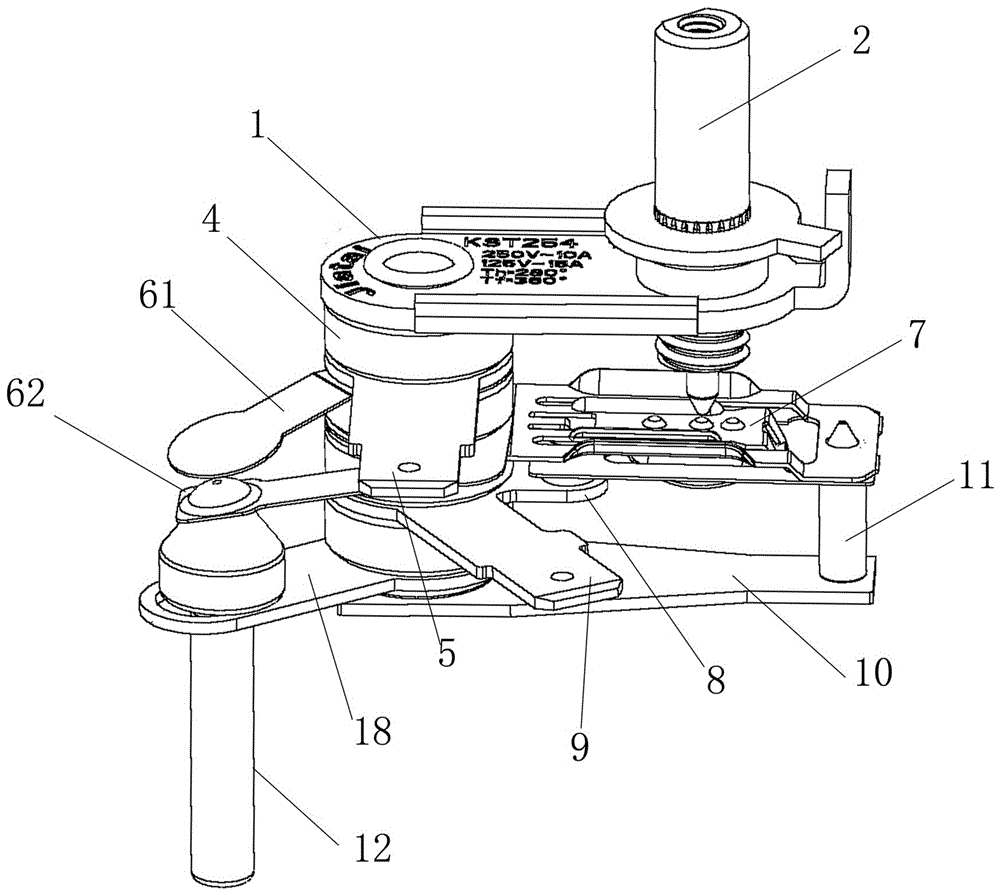

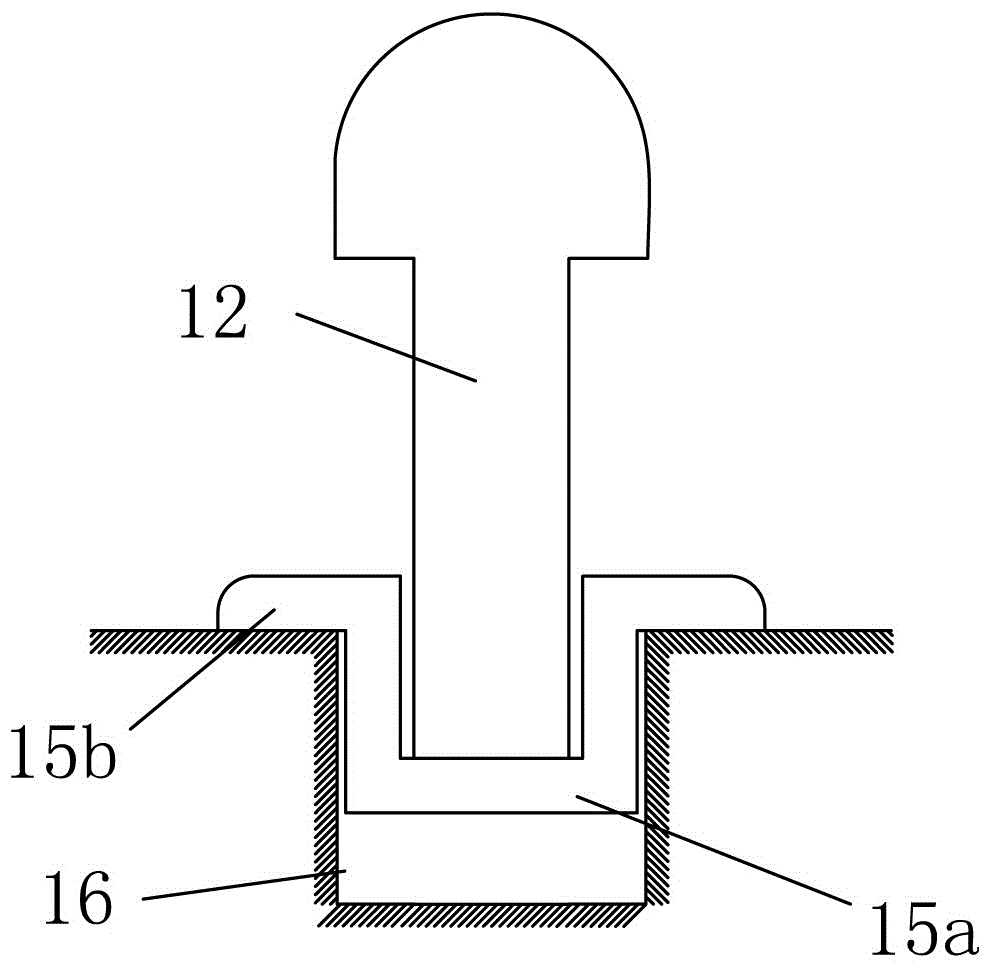

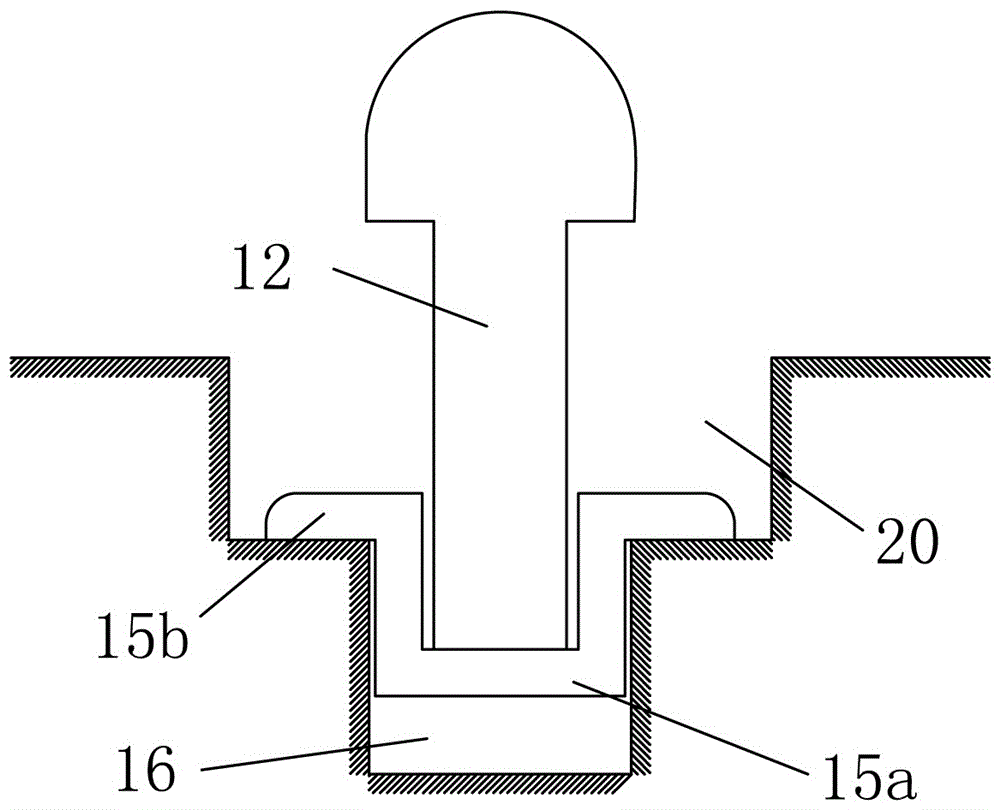

[0021] Such as figure 1 , figure 2 , Figure 6 As shown, a specific embodiment of the electric iron thermostat of the present invention is a kind of electric iron thermostat, which includes a connecting column 1, a spiral temperature regulating device 2, a fixing piece 3 of the temperature regulating device, several ceramic rings 4, and an input piece 5. The upper safety plate 61, the lower safety plate 62, the moving contact piece 7, the static contact piece 8, the output piece 9, the bimetallic piece 10, the ceramic rice 11 and the over-temperature protection ejector rod 12, the spiral temperature regulating device 2 is installed On the fixed piece 3 of the temperature regulating device, the bimetal 10 is fixedly connected to the heating base plate of the electric iron, and the bimetal 10 drives the ceramic rice 11 to control the electrical contact between the moving contact piece 7 and the static contact piece 8 . The heating base plate of the electric iron is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com