Inkjet head, inkjet recording device and manufacturing method of vibration damping component

A manufacturing method and inkjet head technology, applied in printing and other directions, can solve the problems of loss of vibration damping effect, reduction of pressure wave attenuation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

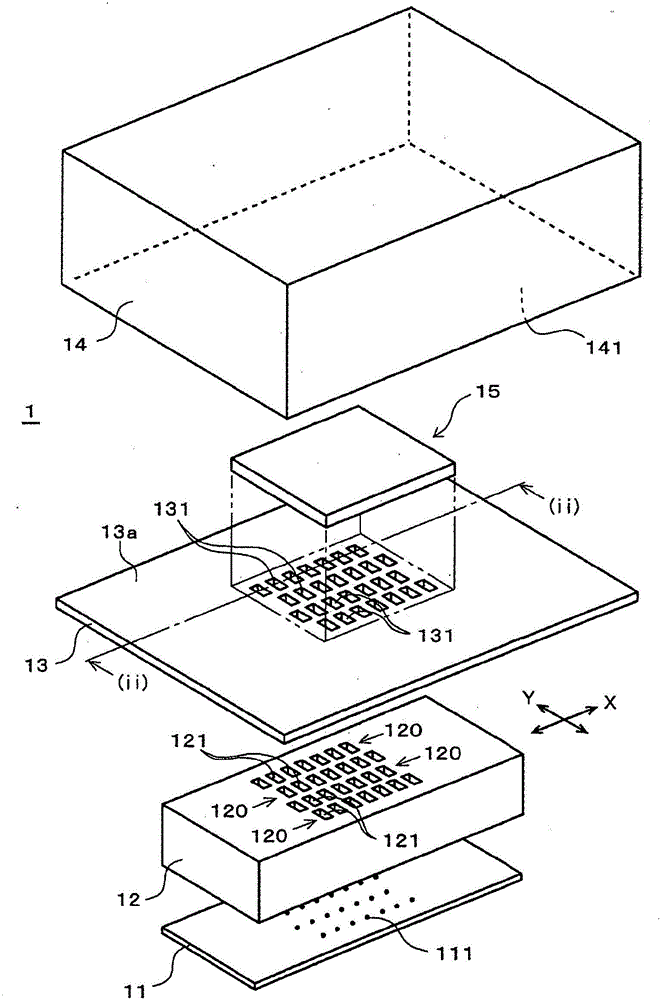

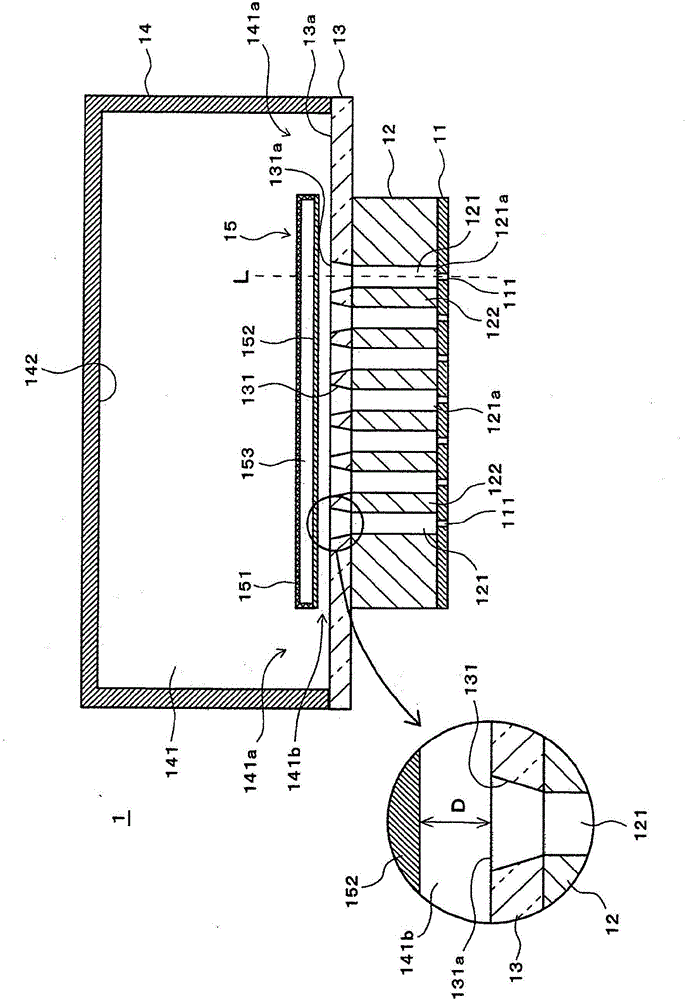

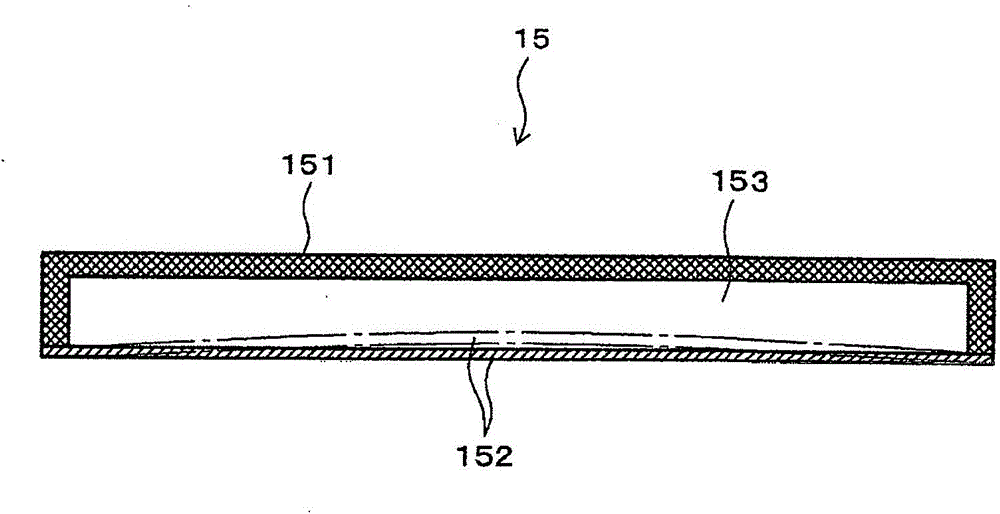

[0151] figure 1 It is an exploded perspective view showing an example of the first embodiment of the inkjet head of the present invention, figure 2 is along figure 1 The cross-sectional view of the inkjet head cut by the line (ii)-(ii), image 3 is a cross-sectional view of the damper.

[0152] Inkjet head 1 from figure 1 The nozzle plate 11 , the inkjet head chip 12 , the substrate 13 , and the ink manifold 14 are provided in this order from the lower part, and the inkjet head 1 is formed by bonding these components to each other. The damping member 15 is arranged inside the common ink chamber 141 formed by the inner space of the ink manifold 14 .

[0153] The inkjet head chip 12 shown in this embodiment has a hexahedron shape, and a plurality of pressure chambers 121 are arranged therein. Each pressure chamber 121 is formed so as to pass through in a straight line across the surface of the head chip 12 on the nozzle plate 11 side and the surface on the substrate 13 sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com