Portable 360-degree video shooting instrument

A video shooting, portable technology, applied in the direction of TV, color TV, color TV parts, etc., can solve problems such as troublesome, manpower and time consumption, prone to problems, etc., and achieve the effect of low shooting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

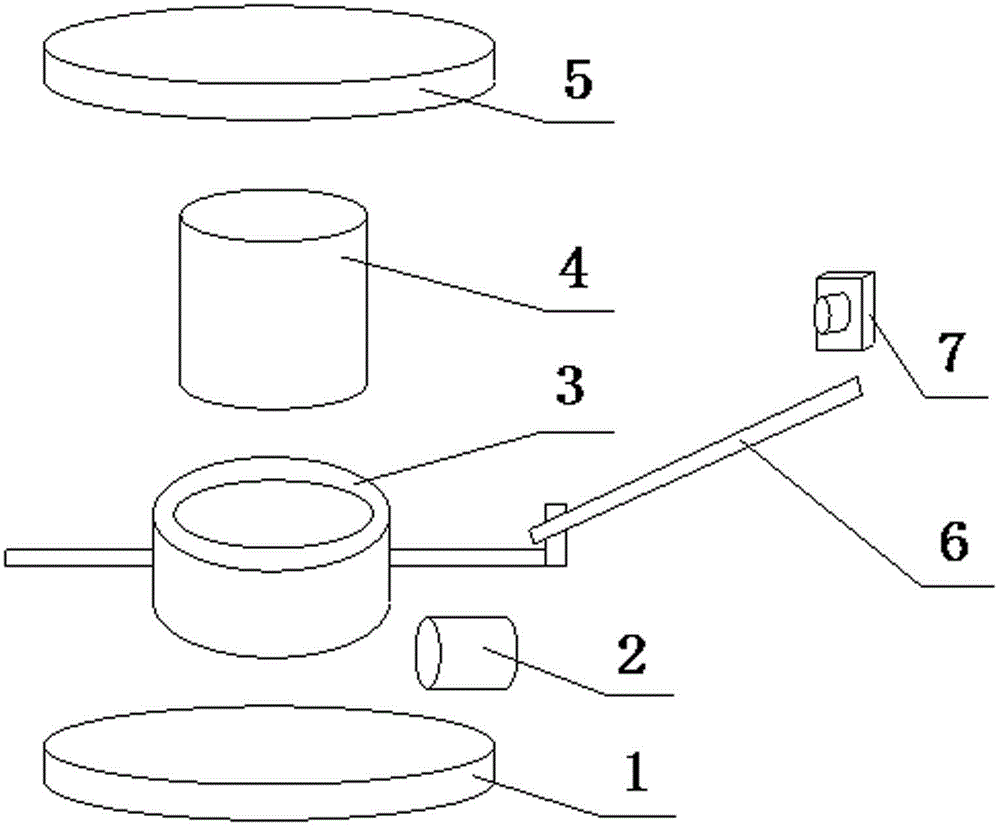

[0007] The structure of the portable 360-degree video camera of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0008] see figure 1 , the portable 360-degree video camera of the present invention comprises a chassis 1, a load-bearing shaft 4 is established in the middle of the chassis 1, and a bearing 3 driven by a motor 2 to rotate along the load-bearing shaft 4 is established on the load-bearing shaft 4, and the rotating speed of the motor 2 can be adjusted. A mechanical arm 6 whose length and angle can be adjusted is established on the bearing 3 , a video camera 7 is established at the outer end of the mechanical arm 6 , and a load-bearing disc 5 is established at the upper end of the load-bearing shaft 4 . The load-bearing plate 5 of the present invention, the load-bearing shaft 4, and the chassis 1 are combined into a load-bearing system for people to stand on, and can withstand people jumping or dancing or doing st...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap