Connecting rod type variable grasping force cooperative self-adaptive finger device

A grasping force, self-adaptive technology, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems that the device is difficult to provide a wider range of grasping force, the finger quickly collides with the object, and the locking effect is affected. The effect of fast and stable process, continuous joint angle, low assembly and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

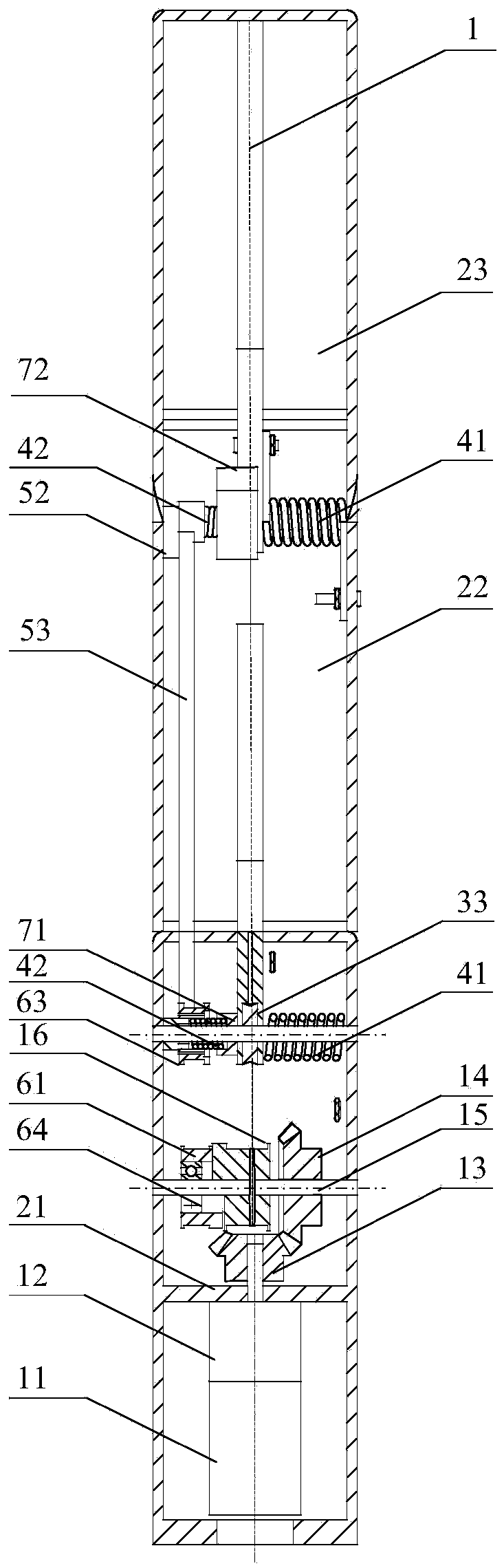

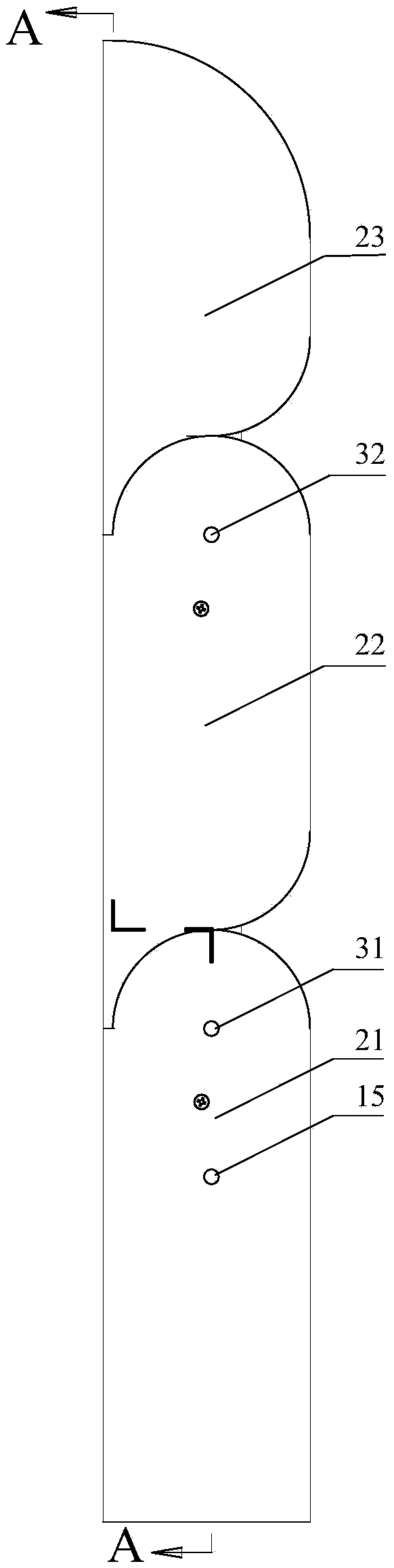

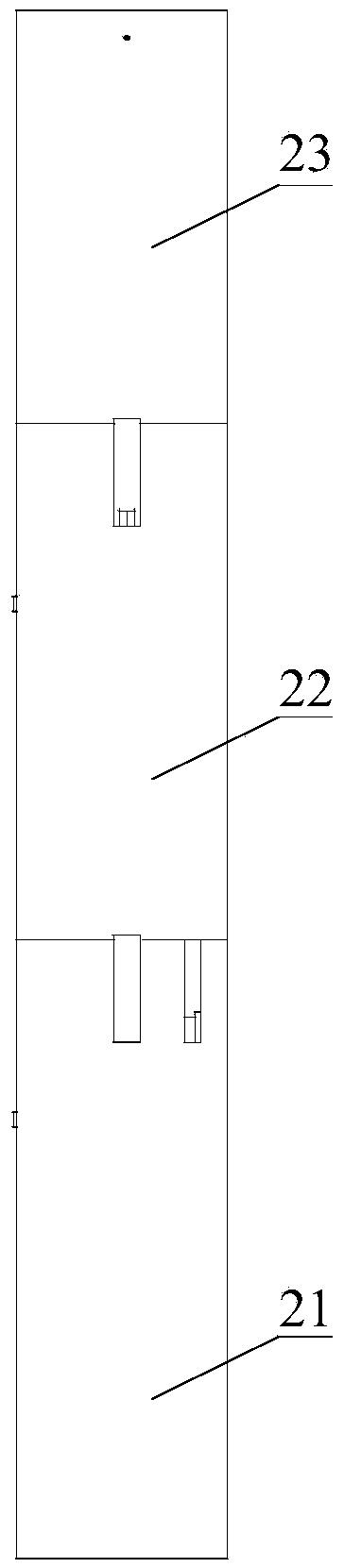

[0047] The specific structure, working principle and working process of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0048] The present invention provides a link-type variable grasping force cooperative self-adaptive finger device, which includes a motor, a reducer, a first transmission mechanism, a tendon rope, a pull rope, N finger segments, N-1 joint shafts, N-1 articulated wheels and N-1 first-type spring parts; the motor is fixedly connected to the first finger segment, the output shaft of the motor is connected to the input shaft of the reducer, and the output shaft of the reducer It is connected to the input end of the first transmission mechanism; the output end of the first transmission mechanism is connected to the pull rope, and the pull rope is fixedly connected to one end of the tendon rope, and the other end of the tendon rope is fixedly connected to the last finger segment ; The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com